Cigarette filter structure with built-in negative pressure drive fitting

A filter and cigarette technology, applied in tobacco, tobacco pipe, application, etc., can solve the problems of cigarette butt deformation, waste of smoke, difficulty in restoring the original shape, etc., and achieve the effects of reducing nicotine gas, filtering harmful substances, and improving airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

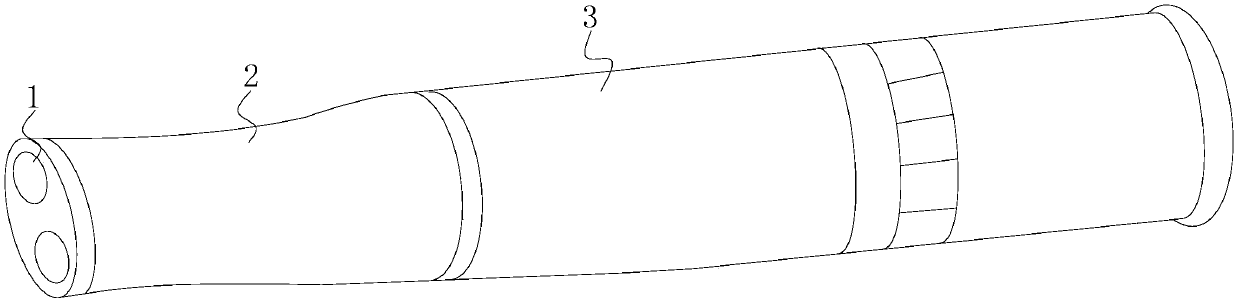

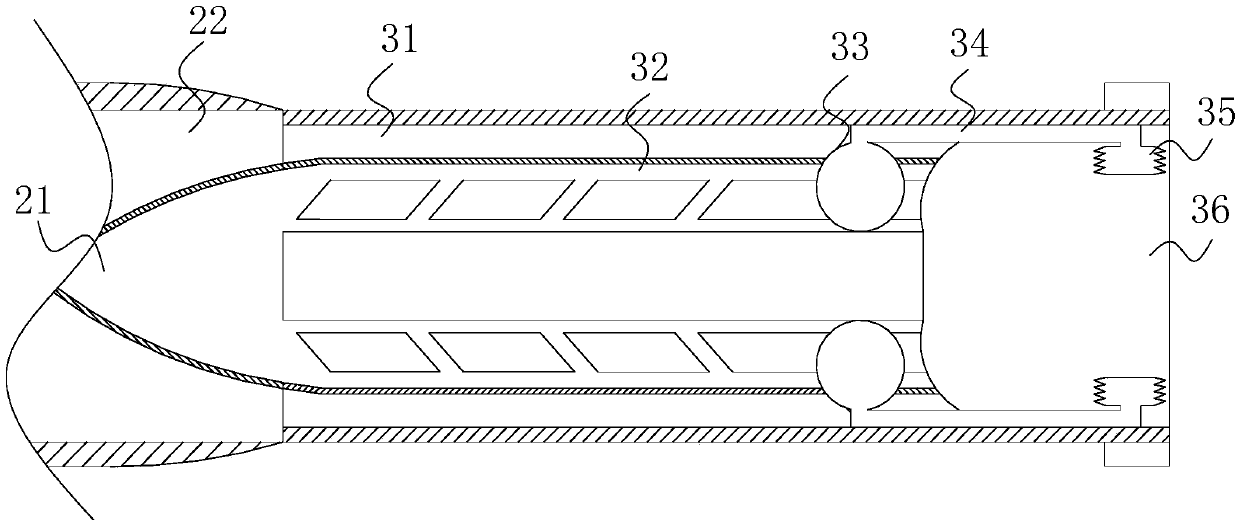

[0026] Such as Figure 1-Figure 4 As shown, the present invention provides a cigarette filter tip structure with a built-in negative pressure drive fit, the structure includes a suction tip 1, a filter area 2, and a cigarette area 3, and the inside of the filter area 2 is provided with a suction port 21 and a filter element 22. The suction nozzle 1 is sleeved at the port position of the filter area 2. The filter area 2 and the cigarette area 3 are integrated to form a cylindrical structure. The suction port 21 runs through the filter element 22 and cooperates with the suction nozzle 1. The suction port 21 is a rhombus structure with a through hole on the outside of one end, and the suction nozzle 1 is provided with double ports.

[0027] One end of the filter element 22 opposite to the suction nozzle 1 is in contact with the interior of the cigarette area 3 .

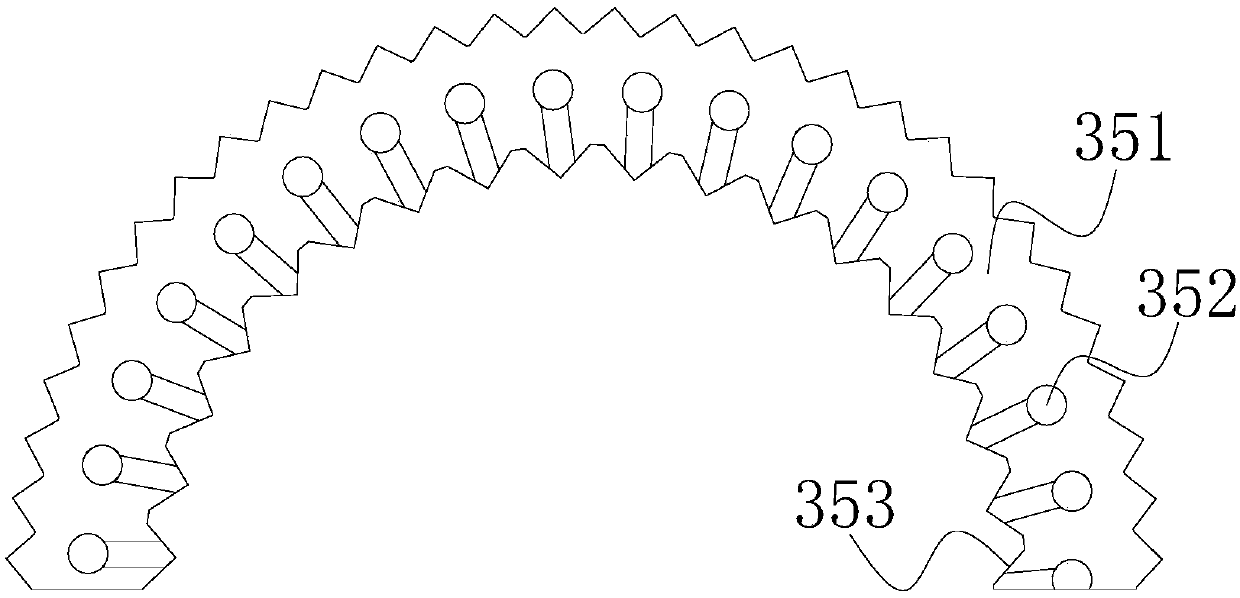

[0028] The interior of the cigarette area 3 includes a cavity 31, a suction channel 32, a negative pressure ball 33,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com