Industrial soft body capturing robot

An industrial and robotic technology, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problem of difficult work of rigid manipulator devices, and achieve the effects of fast response speed, high power density and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

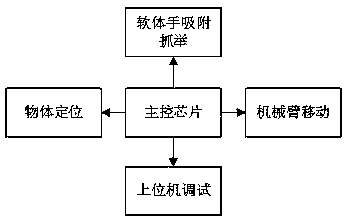

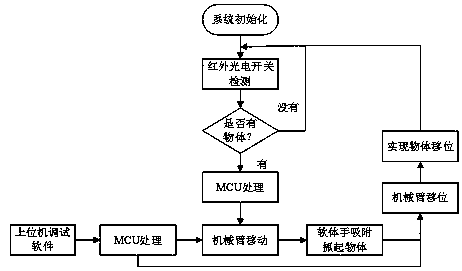

[0022] The invention provides an industrial software grabbing robot. The robot uses a spherical soft gripper. By inflating the structure, the air pressure causes the structure to deform or move, thereby realizing driving grabbing. It is mainly used in industrial production and can be suitable for For grasping objects of different shapes.

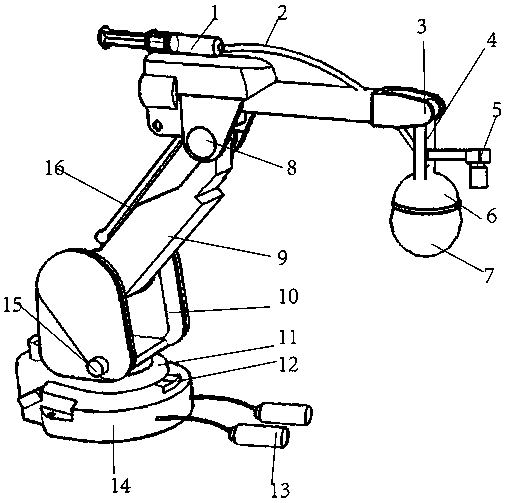

[0023] As an embodiment of the present invention, the present invention provides an industrial soft grasping robot, including a vacuum pump 1, a connecting pipe 2, a mechanical arm 3, a soft hand connecting frame 4, a camera 5, a soft hand fixing frame 6, a spherical soft Hand 7, mechanical arm motor 8, mechanical arm two 9, mechanical arm fixed mount 10, bottom rotating bearing 11, control panel 12, base 14 and mechanical arm cylinder 16, bottom rotating bearing 11 is arranged in the described base 14, so A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com