Welding and shaping mechanism of brake shoes

A brake shoe and welding machine technology, applied in the direction of manufacturing tools and other manufacturing equipment/tools, can solve the problems of occupying human resources, occupying production space, and low production efficiency, so as to save human resources, improve production efficiency, Reduce the effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

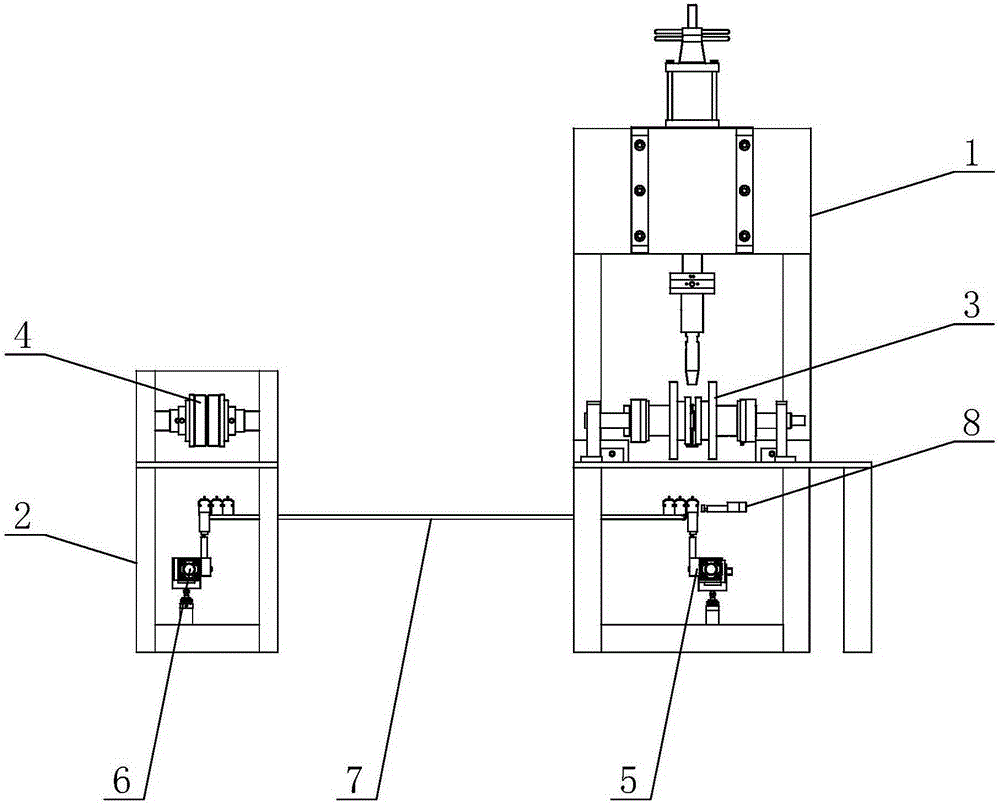

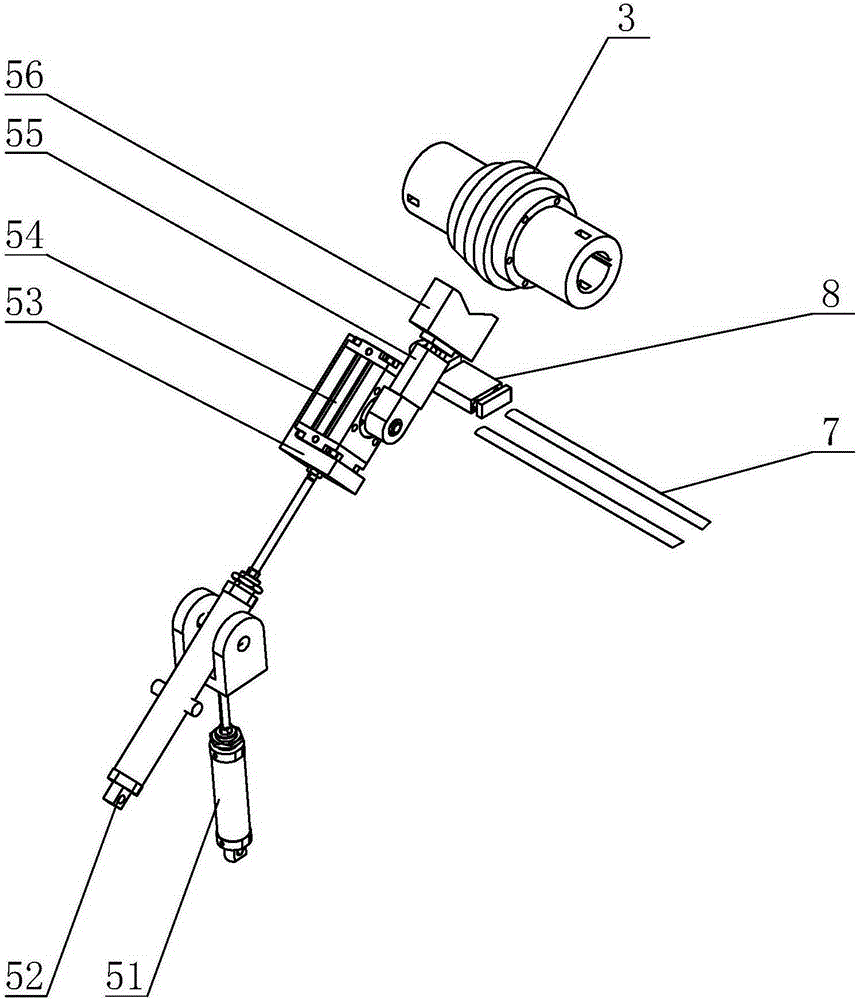

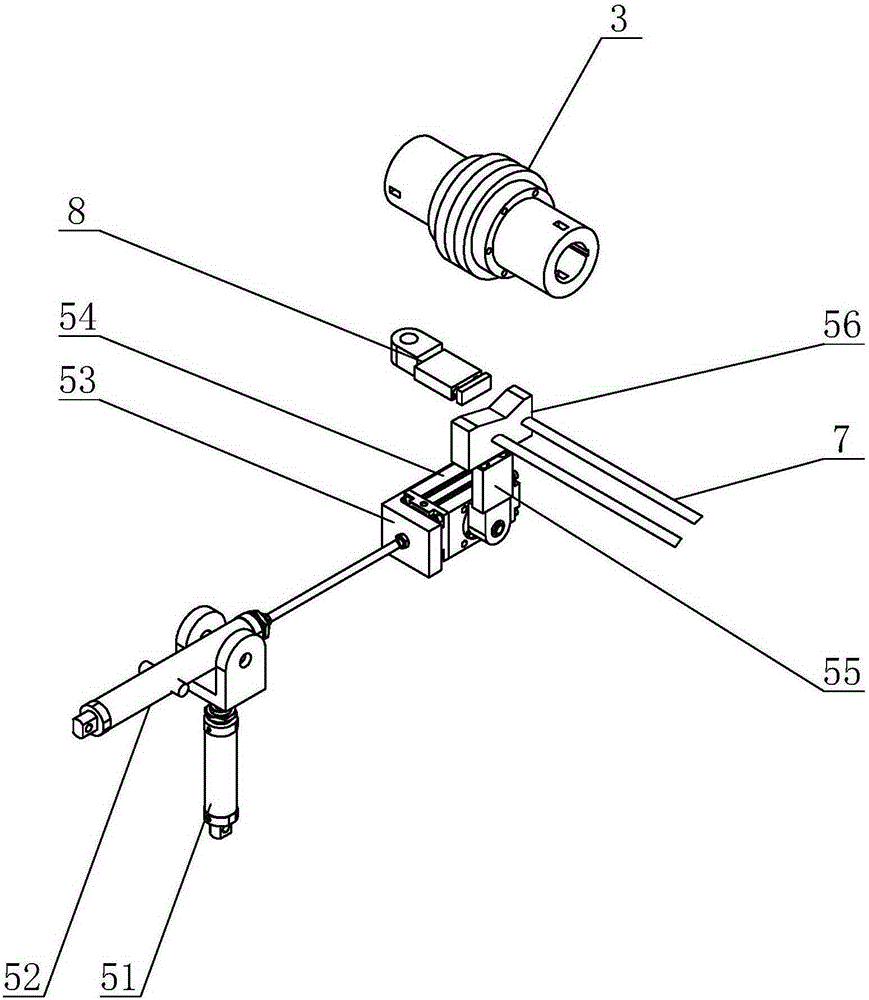

[0040] Embodiment: The present invention is a welding and shaping mechanism for a brake shoe, including a welding machine and a shaping machine. The welding machine can complete the welding of the brake shoe, and the shaping machine can complete the shaping of the brake shoe. A welding chuck is set on the welding machine, and a shaping chuck is set on the shaping machine. A transfer mechanism is set between the welding machine and the shaping machine, and the transfer mechanism can transfer the welded brake shoes to the shaping machine, which can reduce the use of turnover boxes, reduce the occupation of production space, and can combine welding and shaping into one One process can save human resources. The transfer mechanism includes a material receiving device arranged under the welding chuck and a feeding device arranged under the shaping chuck. A transfer guide rail is arranged between the material receiving device and the feeding device. The transfer guide rail adopts two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com