Foam sheet machine pre-storage material device capable of effectively preventing particle damage

A technology of pre-storage and granules, which is applied in the field of pre-storage devices of foam board machines, can solve the problems such as the destruction of foam regular gaps, affecting the thermal insulation performance of insulation boards, and the inability of foam particles to ensure a near-circular shape, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

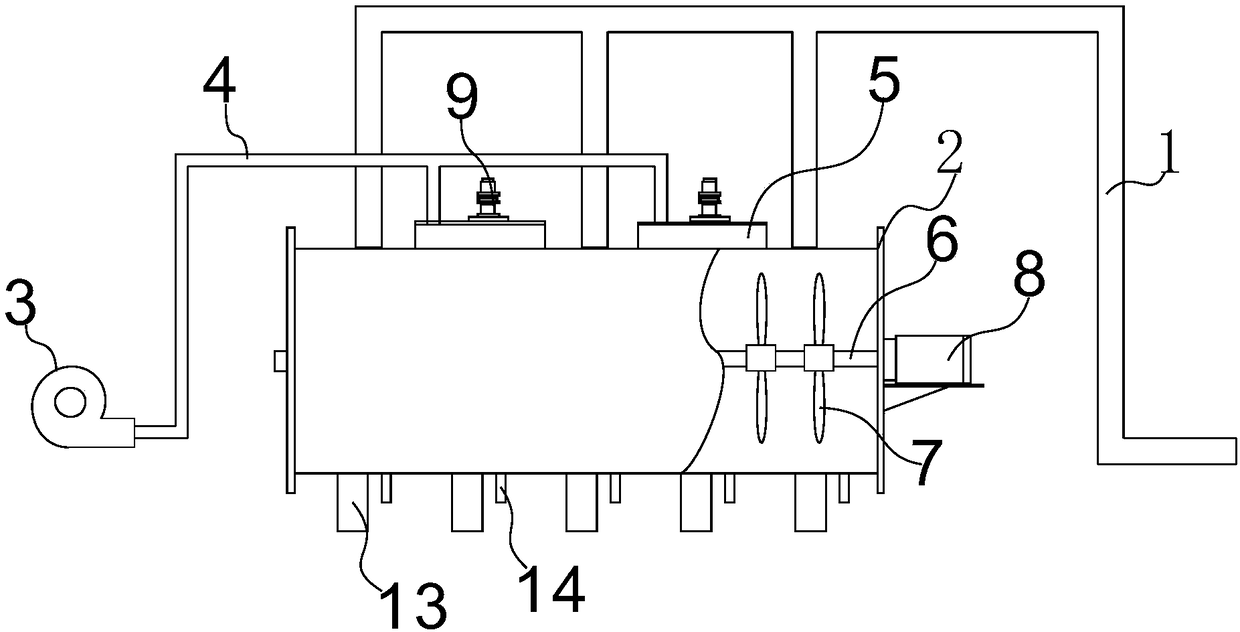

[0016] As shown in the figure, the present invention includes a feeding pipe 1, a pre-storage hopper 2 and a fan feeding mechanism whose top communicates with the feeding pipe, wherein,

[0017] Described blower blower feeding mechanism comprises induced draft fan 3, and the air inlet pipe 4 that is communicated with induced draft fan and is located at the filter box 5 of pre-stored hopper top, and the bottom of described filter box is communicated with pre-stored hopper, is provided with filter screen (Fig. Not shown in), the top of the filter box communicates with the air inlet pipe;

[0018] The feeding pipe can be provided with multiple branches at the front end, and the multiple branches are connected to the feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com