Equipment and method for preparing columnar amalgam in use for fluorescent lamp

A technology for cylindrical and fluorescent lamps, applied in the field of alloy materials for fluorescent lamps, can solve the problems of poor size consistency and irregular shape of cylindrical amalgams, and achieve the effect of consistent diameter and regular shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

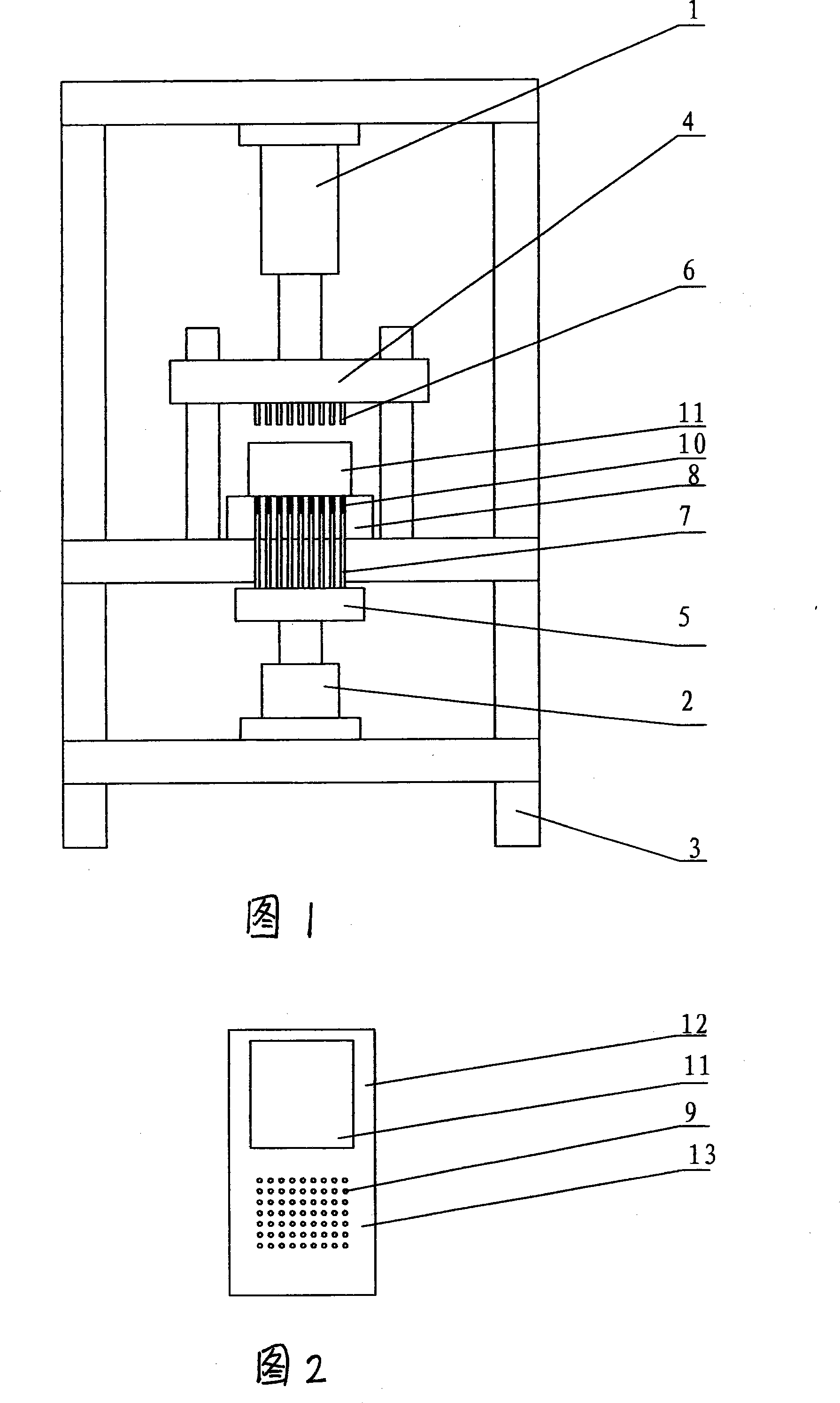

[0010] As shown in accompanying drawing 1 and accompanying drawing 2, the equipment for preparing cylindrical amalgam for fluorescent lamps according to the present invention includes stamping cylinder 1, top cylinder 2 and frame 3, and upper template 4 is fixedly installed on stamping cylinder 1 , the lower formwork 5 is fixedly installed on the top cylinder 2, the punch pin 6 is fixedly installed on the upper formwork 4, the thimble 7 is fixedly installed on the lower formwork 5, and the bottom mold 8 is provided with several bottom mold holes 9, and the upper part of the thimble 7 is In the die hole 9 of the bottom mold. Under the action of the upper cylinder 2, the thimble 7 can move up and down in the die hole 9 of the bottom die.

[0011] Mix mercury and metal powder evenly according to a certain ratio, then put it into a container, evacuate the container into a vacuum or fill it with argon gas of 0.01-0.05MPa, heat it to 90-250°C, and wait for the mercury and metal to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com