A mechanical anti-theft lock for automobile

A mechanical anti-theft lock and automobile technology, applied in the field of automotive mechanical anti-theft locks, can solve the problems of simplification of functions, difficulty in fixing, and poor practicability, and achieve the effects of diversified functions, full use of space, and low installation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

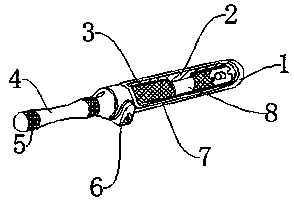

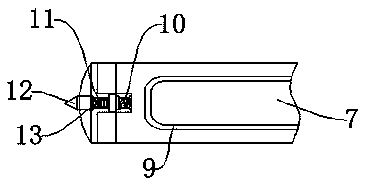

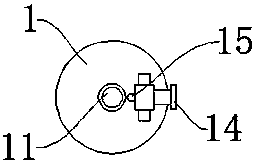

[0037] Such as Figure 1-Figure 7As shown, a kind of automobile mechanical antitheft lock of the present invention comprises antirust lock body 1, and the surface of antirust lock body 1 is provided with steering wheel placement groove 7, and the side wall of steering wheel placement groove 7 is provided with protective rubber cover 9, and antirust lock body 1. A flexible protective pad 3 is provided on the inner wall. A lock tongue 2 is provided inside the anti-rust lock body 1. A rubber-coated stopper 8 is provided on the lock tongue 2. A locking device 6 is provided at the bottom of the anti-rust lock body 1. The locking device 6. One side is provided with a metal handle 4, and the outer wall of the metal handle 4 is provided with anti-slip lines 5. The end of the anti-rust lock body 1 is provided with a safety hammer nail head 12, and a transmission rod 11 is arranged below the safety hammer nail head 12. The transmission rod 11 One side is provided with a first limiting b...

Embodiment 2

[0039] The difference between this embodiment and Embodiment 1 is:

[0040] In this embodiment, the depth range of the limiting groove 13 is not less than 5 mm, and the lock tongue 2 is provided with a through hole for fixing with the lock core 16 at a position close to the lock core 16 . This setting can improve the fixing effect of the device and increase the anti-theft capability of the device. There are two support seats 34, and the two support seats 34 are symmetrically distributed on both sides of the transmission gear 28. The anti-tilt gear 32 is fixed inside the support seat 34 by a pin, and the anti-tilt gear 32 is meshed with the rack 30, so that The setting can ensure that the rack 30 can move smoothly.

[0041] The working principle of the anti-theft lock in the present invention is: when carrying out anti-theft measures for automobiles, the operator can align the steering wheel placement groove 7 on the antirust lock body 1 with the steering wheel and embed it in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com