Rotor assembly of centrifugal machine

A centrifuge and rotor technology, applied in centrifuges and other directions, can solve the problems of poor corrosion resistance, poor mechanical strength performance, and prone to noise, etc., achieve reasonable product structure design, improve mechanical strength performance and corrosion resistance performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

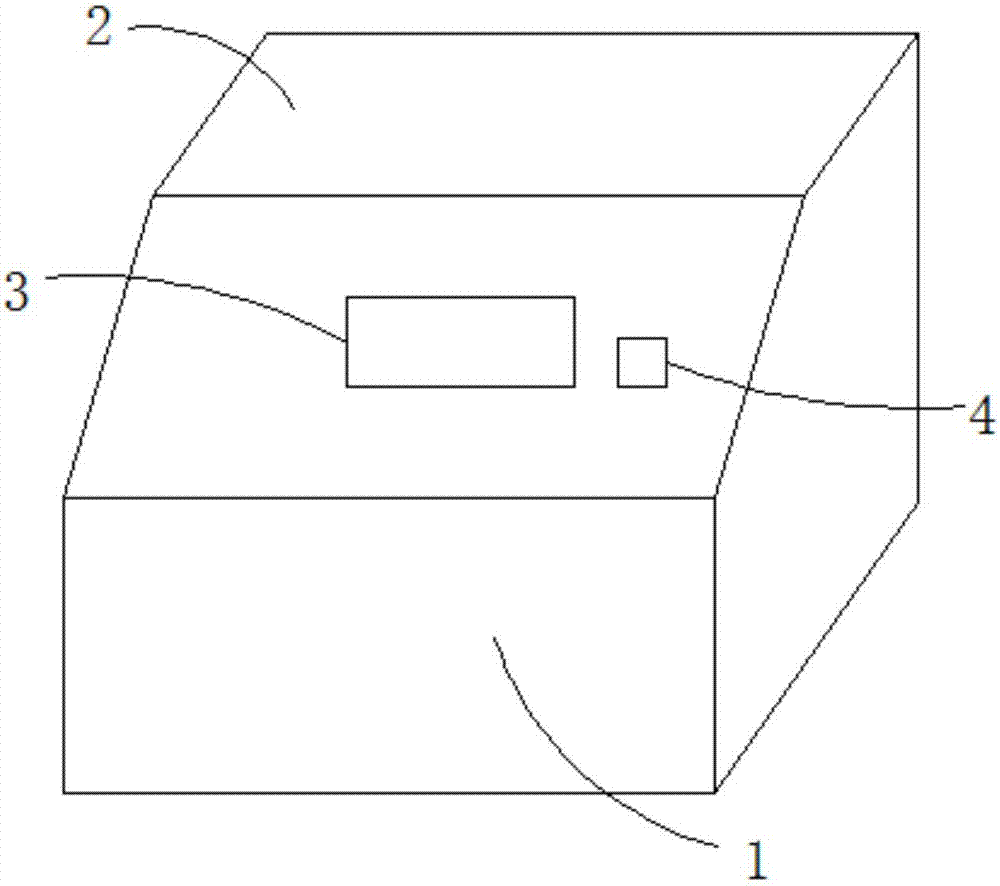

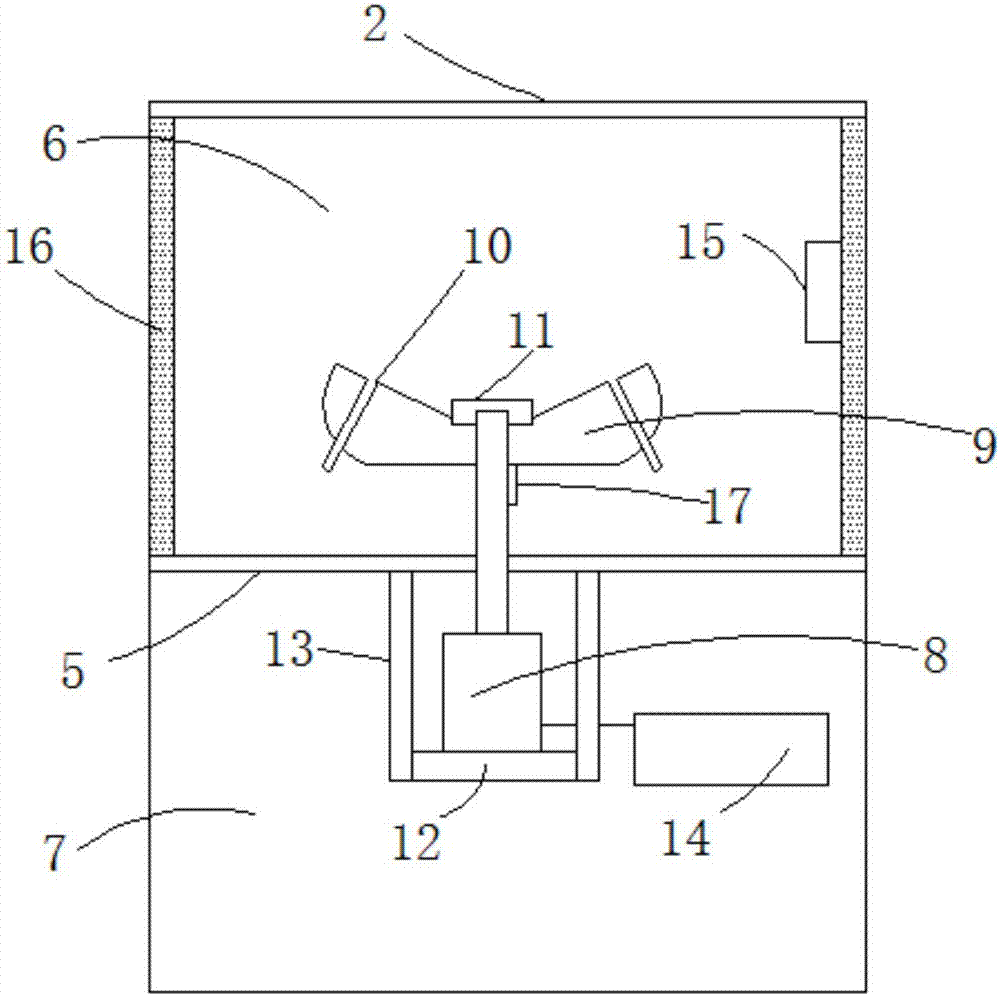

[0028] see figure 1 and figure 2 , the present invention provides a centrifuge, comprising: a housing 1, a cover plate 2 connected to the housing 1, a display screen 3 and a switch 4 arranged on the housing 1, a The centrifugal cavity 6 and the motor cavity 7 inside, the partition plate 5 that separates the centrifugal cavity 6 and the motor cavity 7 in the housing 1, is set in the motor cavity 7 and its drive shaft extends to the centrifugal cavity 6 The drive motor 8 inside, the rotor 9 that is located in the centrifugal cavity 6 and links to each other with the drive shaft of the drive motor 8, a plurality of centrifuge tube jacks 10 that are located on the rotor 9, and that are located in the drive The support frame 12 below the motor 8, the connecting rod 13 connecting the support frame 12 and the partition plate 5, the sound-absorbing material 16 provided on the side wall of the centrifugal chamber 6, and the drive shaft provided at the drive motor 8 The positioning k...

Embodiment 2

[0033] A method for processing a rotor assembly of a centrifuge, the steps are as follows:

[0034] ①, structure and molding

[0035] The rotor assembly includes a rotor connected to the drive motor through a drive shaft. Positioning keys are provided on the peripheral surface of the drive shaft, and fixing bolts are provided at the end of the drive shaft. The rotor is circular, and a connecting hole is provided at the center of the rotor. The drive shaft Through the connection hole, the rotor is fixed on the drive shaft through positioning keys and fixing bolts; the rotor is provided with a plurality of centrifuge tube sockets, and the multiple centrifuge tube sockets are symmetrically distributed about the center of the rotor;

[0036] The rotor is cast by carbon steel, and the centrifuge tube socket and the rotor are integrally formed;

[0037] The material of the drive shaft is Q235 steel, and the processing technology is forging;

[0038] Positioning keys, fixing bolts,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com