Fan assembly of tea seed processing shucking device

A tea seed shell and fan technology, which is applied in the direction of shelling, solid separation, and separation of solids from solids with airflow, can solve the problems of poor shelling rate and separation effect, complex structure, etc., and achieve product structure design Reasonable, the effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

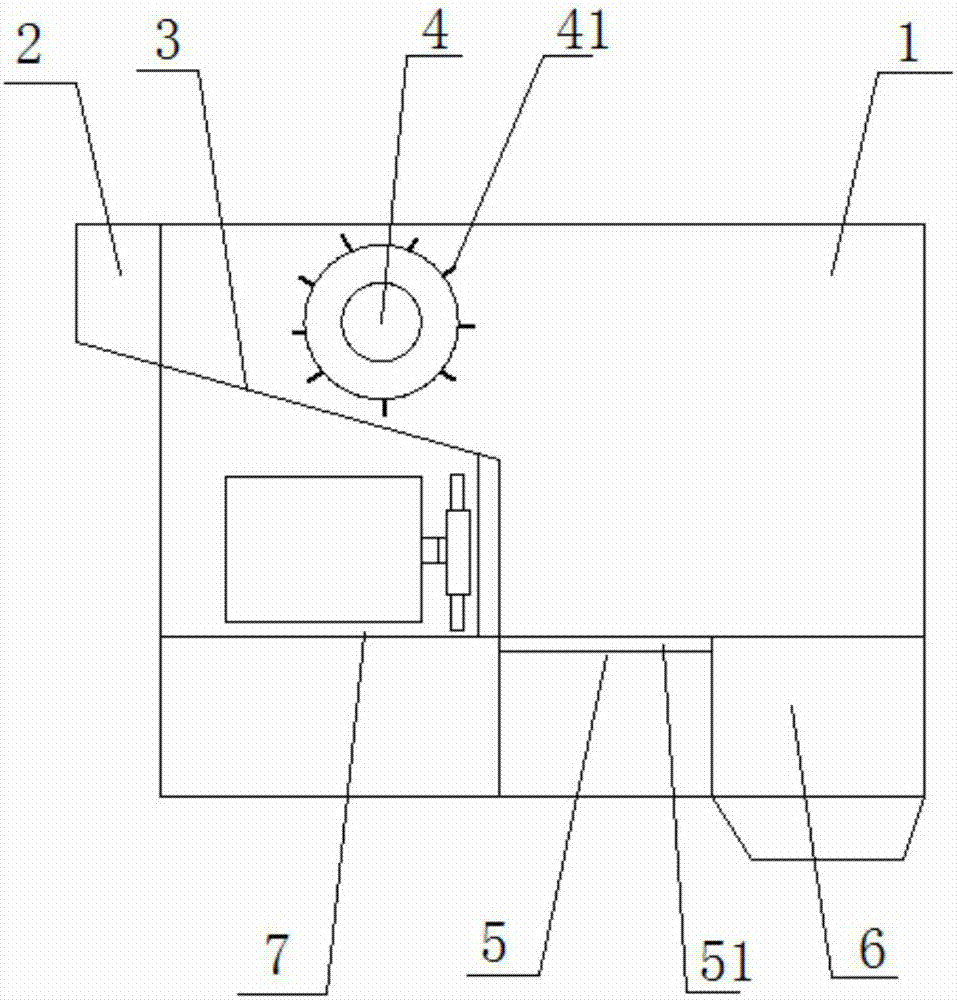

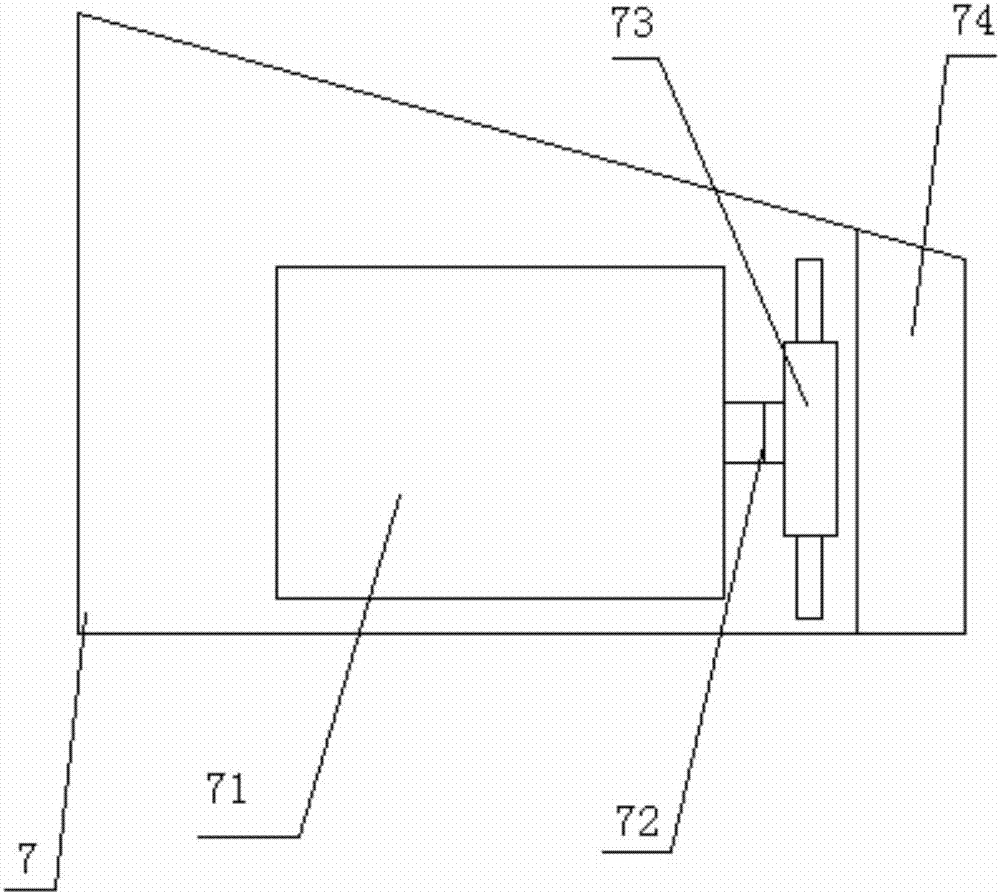

[0026] like Figure 1 to Figure 2 As shown, the present invention provides a tea seed processing and shelling device, comprising: a casing 1, a feed inlet 2 arranged above the end of the casing 1, and a feed inlet 2 arranged inside the casing 1 and connected downwards. Inclined inclined channel 3, turntable 4 located above the inclined channel 3, fan 7 located below the inclined channel 3, separation platform 5 arranged on one side of the fan 7 along the feeding direction, and a separation platform arranged on the side of the fan 7 along the air supply direction of the fan 7 The lower shell 6 on one side of the platform 5. The 4 peripheral surfaces of the rotating disk are provided with shelling rods 41 . A vibration platform 51 is provided below the separation platform 5 . The tea seeds enter the inclined channel 3 from the feed port 2, and the shelling rod 41 dehulls the tea seeds through the rotation of the turntable 4. After shelling, the tea seeds and tea seed shells sl...

Embodiment 2

[0029] A method for processing a fan assembly of a tea seed processing and shelling device, the steps are as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com