A highway life safety system and its construction method

A technology of safety system and construction method, applied in road safety devices, roads, roads and other directions, can solve the problem that the guardrail cannot play a good protective effect, can no longer play a buffering role, etc., and achieve the effect of good protection effect and long buffering distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

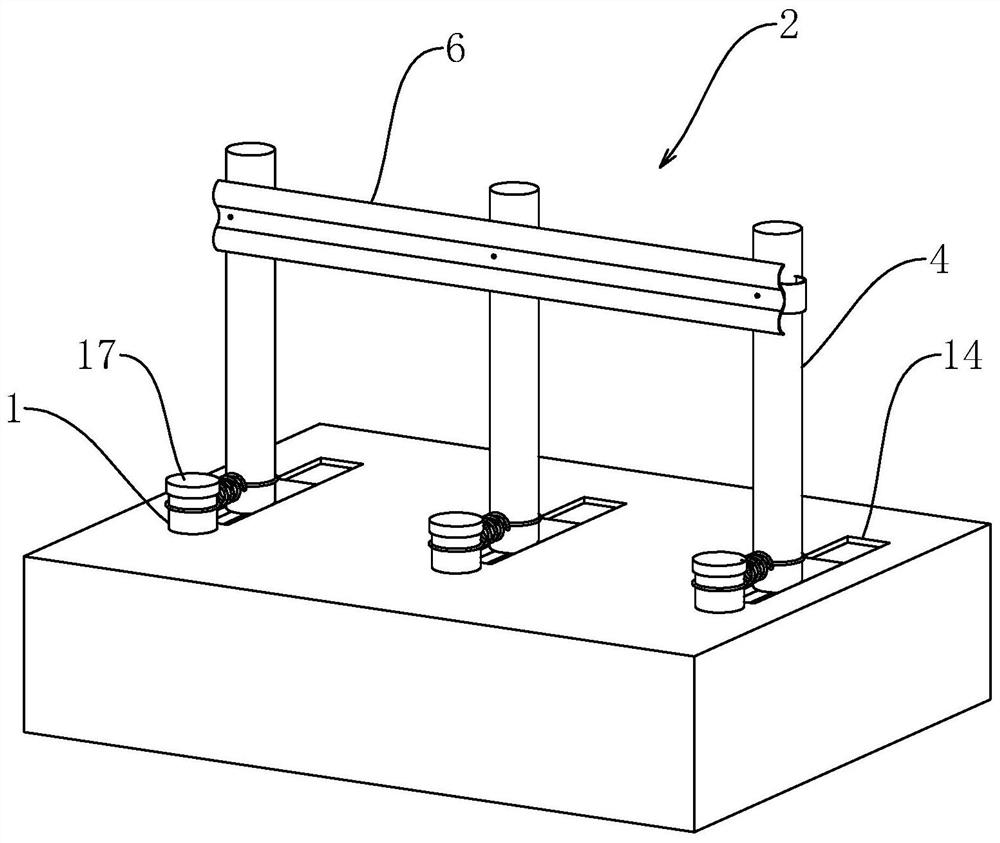

[0046] Such as figure 1 As shown, a highway life safety system includes a plurality of fixed piles 1 for fixing on the road and a buffer mechanism 2 connected to the fixed piles 1 .

[0047] Such as figure 1 As shown, the fixed pile 1 is a cylinder, and the lower end of the fixed pile 1 is inserted into the road and closely connected with the concrete road. The height of the fixed pile 1 beyond the road part is 10-15cm, which is lower than the chassis height of general automobiles.

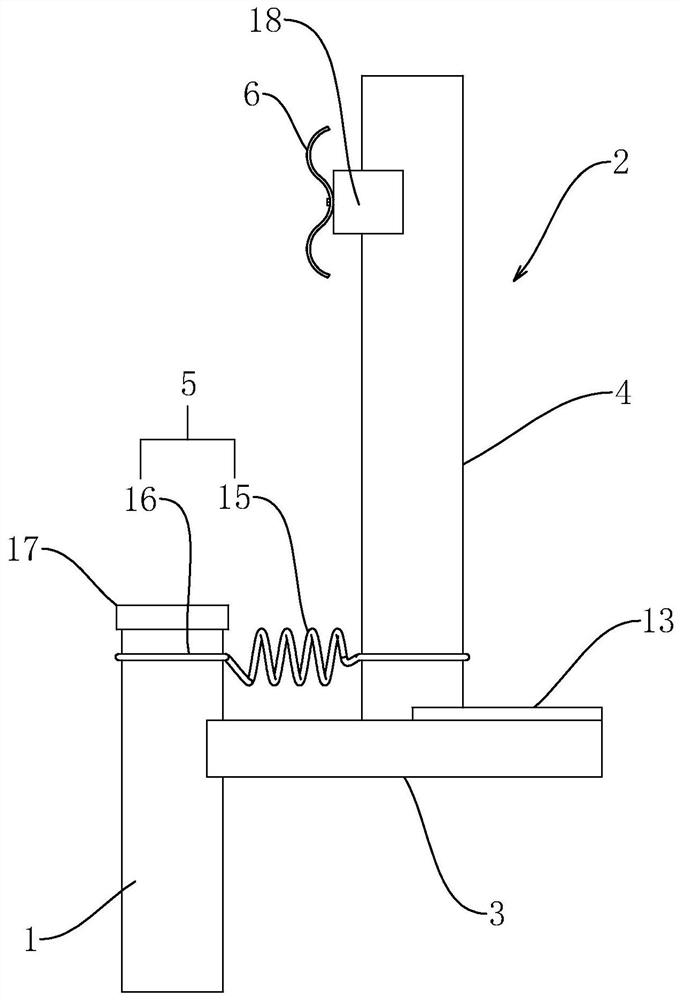

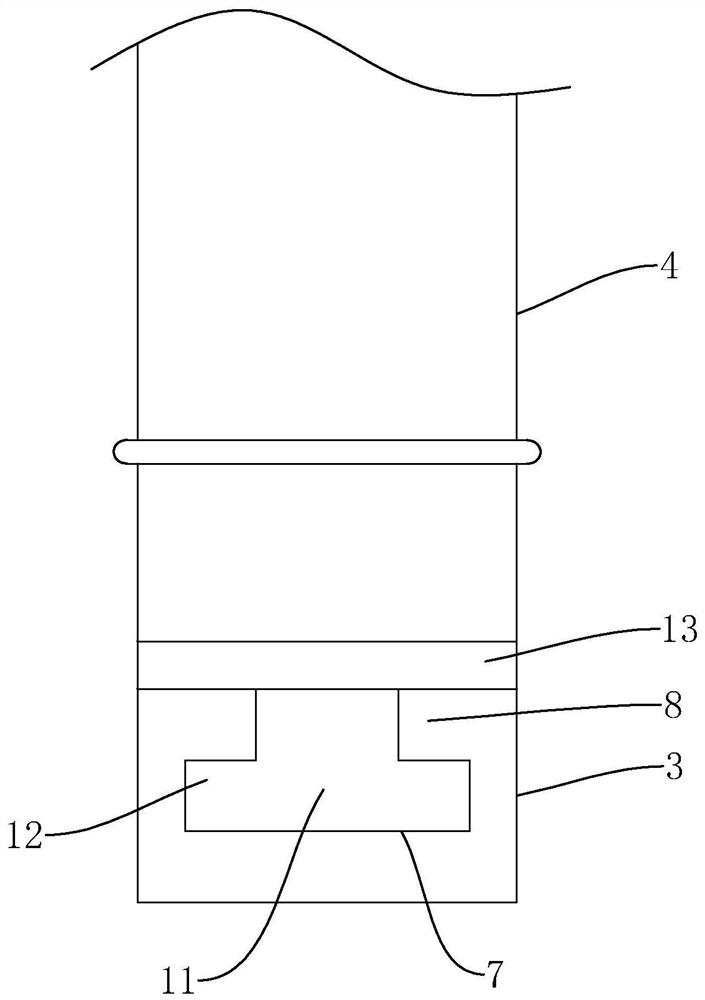

[0048] Such as figure 2 and image 3As shown, the buffer mechanism 2 includes a slide rail 3 welded on the side of the fixed pile 1, a movable column 4 moving along the slide rail 3, an elastic assembly 5 connecting the fixed pile 1 and the movable column 4, and connecting between adjacent movable columns 4 The bar 6. The slide rail 3 is fixed along the horizontal direction, and the upper surface of the slide rail 3 is provided with a slide groove 7, and the two side walls of the slide groov...

Embodiment 2

[0053] A construction method for the above highway life safety system, comprising:

[0054] A. Excavation of foundation pit

[0055] Excavate a foundation pit every 3 meters on both sides of the road. The foundation pit is excavated from both sides of the roadway to the sidewalk side with a length of 1 meter. The width of the foundation pit is 0.2 meters.

[0056] B. Buried fixed pile 1, slide rail 3 and movable column 4

[0057] The movable column 4 is snapped into the slide rail 3 through the slide block 11, and the fixed pile 1, the slide rail 3 and the movable column 4 are buried together in the foundation pit. The gravel cushion is filled through the bottom of the foundation pit so that the upper surface of the shielding plate 13 is flush with the upper surface of the road.

[0058] C. Building wooden formwork

[0059] The first wooden template comprises a horizontal section and a vertical section connected to the lower side of the horizontal section middle part, the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com