Novel vegetable greenhouse fixing device

A vegetable greenhouse and fixing device technology, applied in the agricultural field, can solve the problems of users' economic loss, easy deformation of the skeleton, waste of resources, etc., and achieve the effects of low production cost, reduction of economic loss, and resource protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

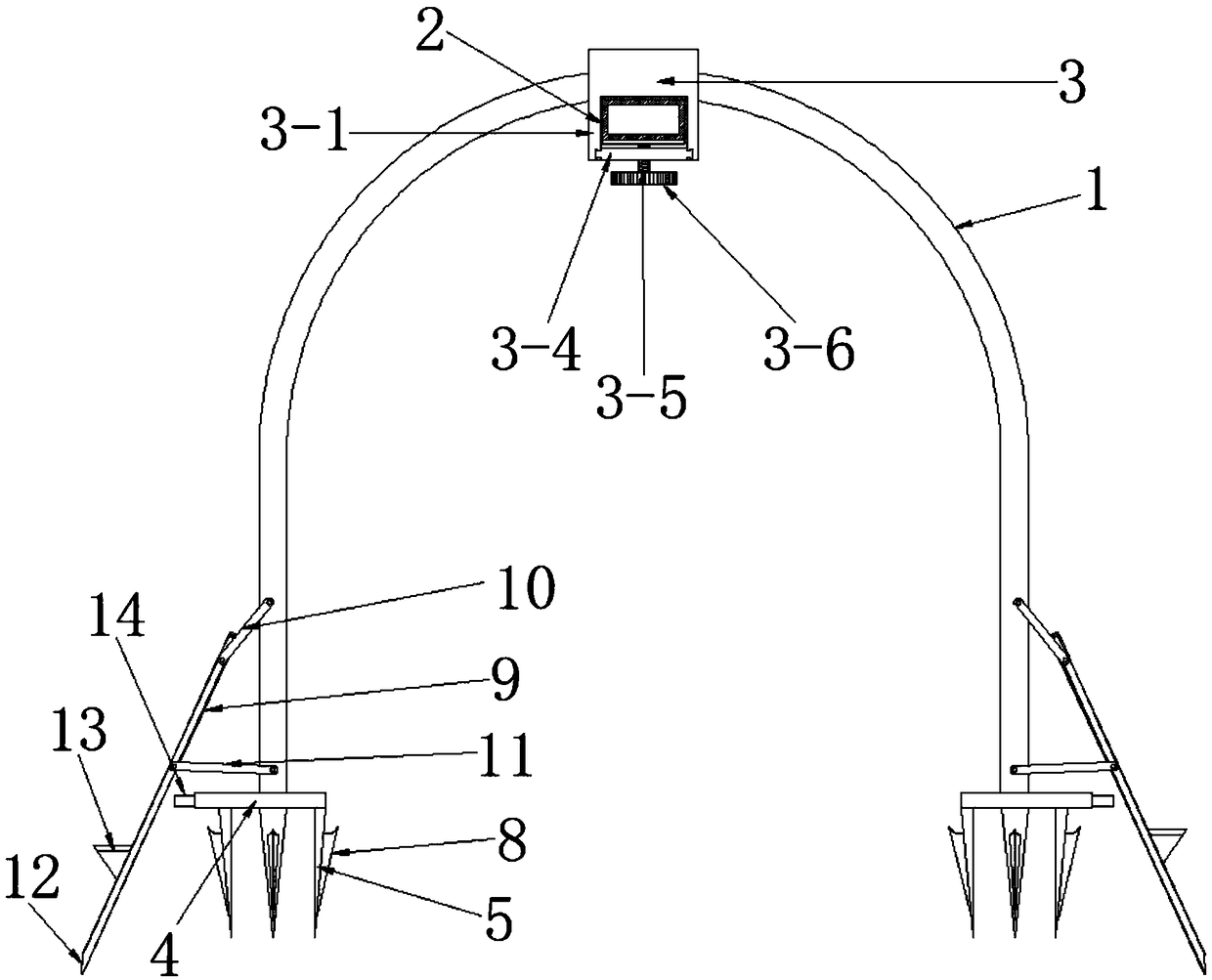

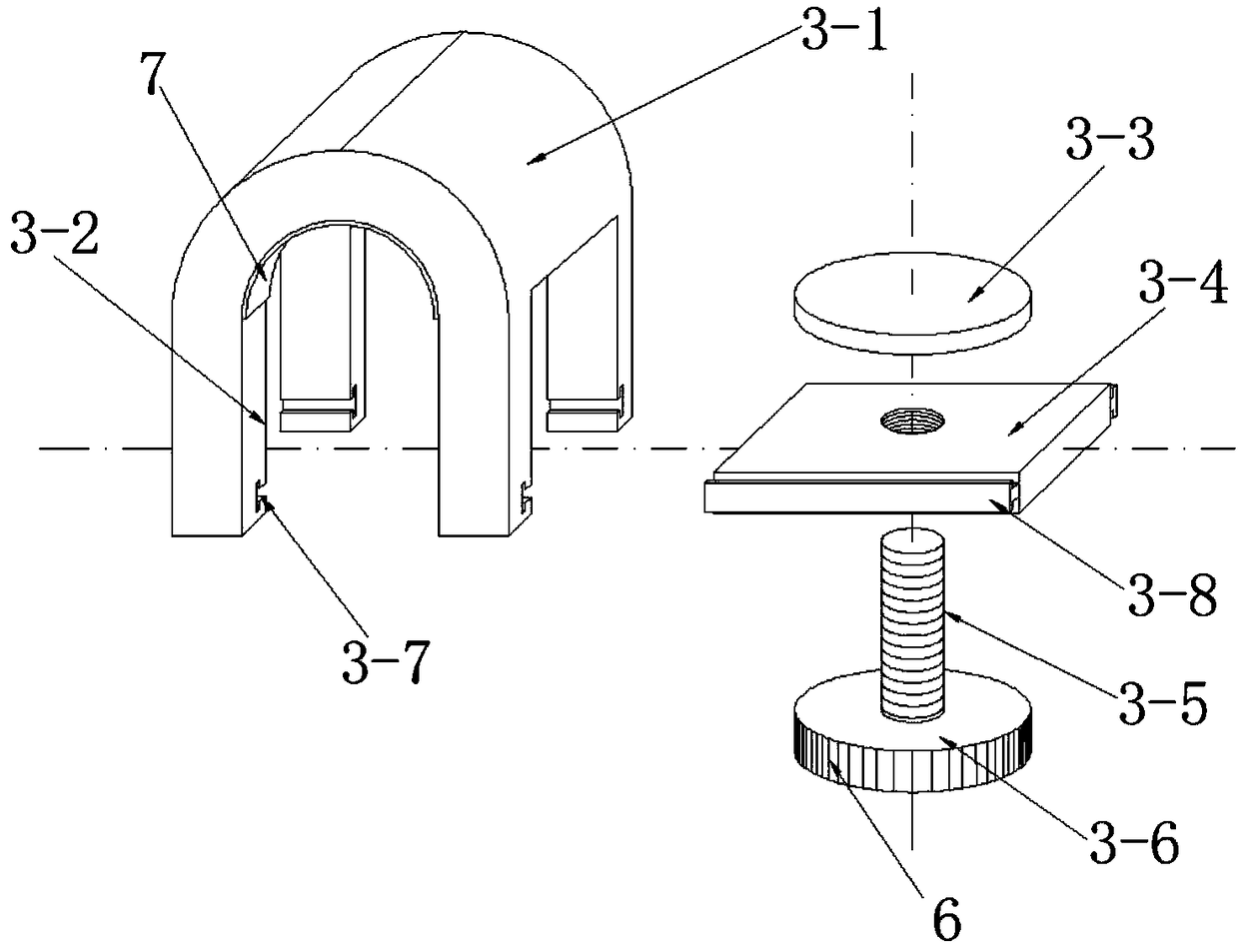

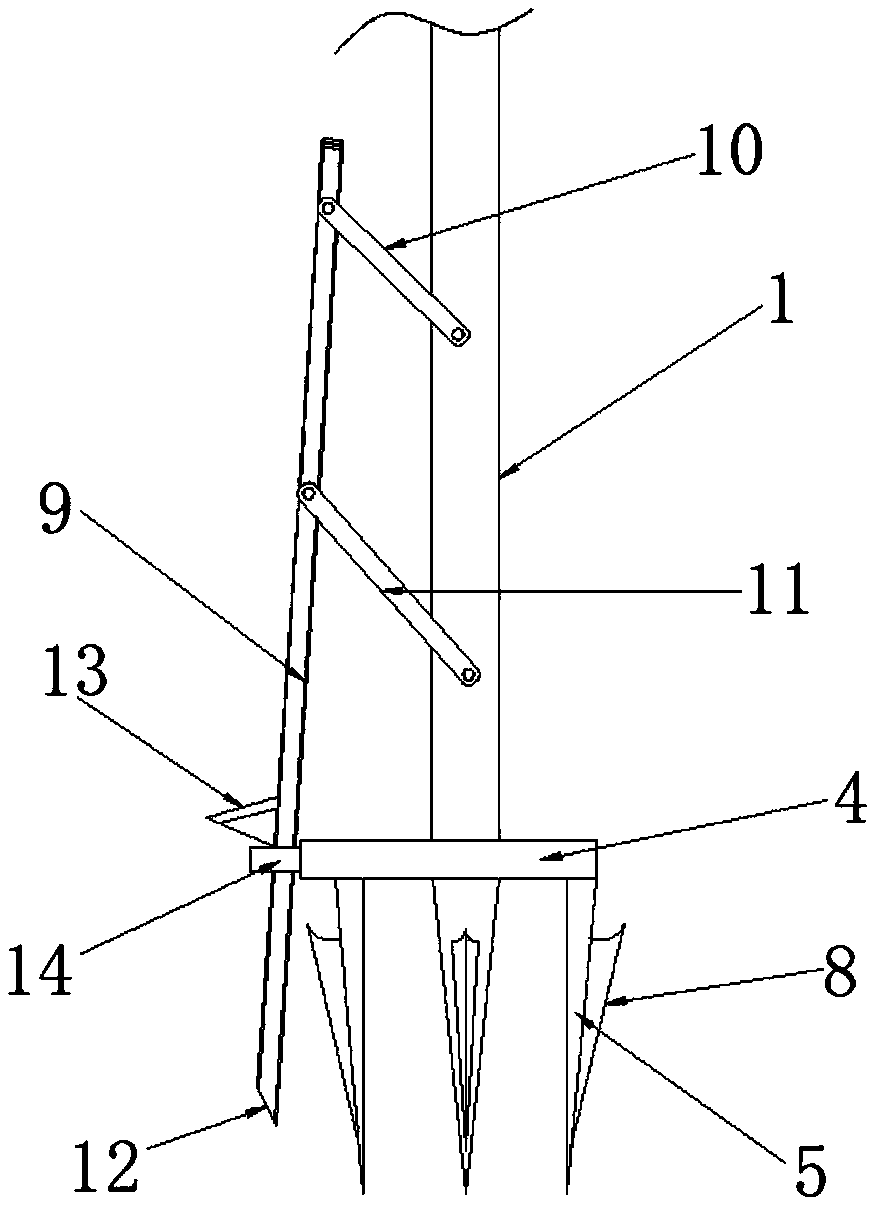

[0018] see as Figure 1-Figure 3 As shown, the technical solution adopted in this specific embodiment is: it includes a supporting frame 1, a connecting device 3, a base 4, a fixing nail 5, and a connecting cross bar 2; the bottom sides of the upper ends of two adjacent supporting frames 1 pass through the connecting device 3 A connecting cross bar 2 is fixedly installed; the connecting device 3 includes a U-shaped card 3-1, a card slot 3-2, a spacer 3-3, a block 3-4, a spacer 3-3, a screw rod 3-5, a hand-tightened 3-6; the upper part of the supporting frame 1 is installed in the card slot 3-2 on the left and right side walls of the U-shaped card 3-1; the connecting cross bar 2 is vertically installed at the bottom of the card slot 3-2; A chute 3-7 is fixedly provided on the inner side wall of the 3-1, and a slider 3-8 is fixedly arranged on both sides of the clamping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com