Transfer trolley used for stacking and destacking of bagged materials

A transfer vehicle and stacking technology, which is applied to trolleys, motor vehicles, single-axis trolleys, etc., can solve the problems that the frame is easy to fall forward, and achieve the effects of convenient and flexible use, improved production efficiency, and reduced workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

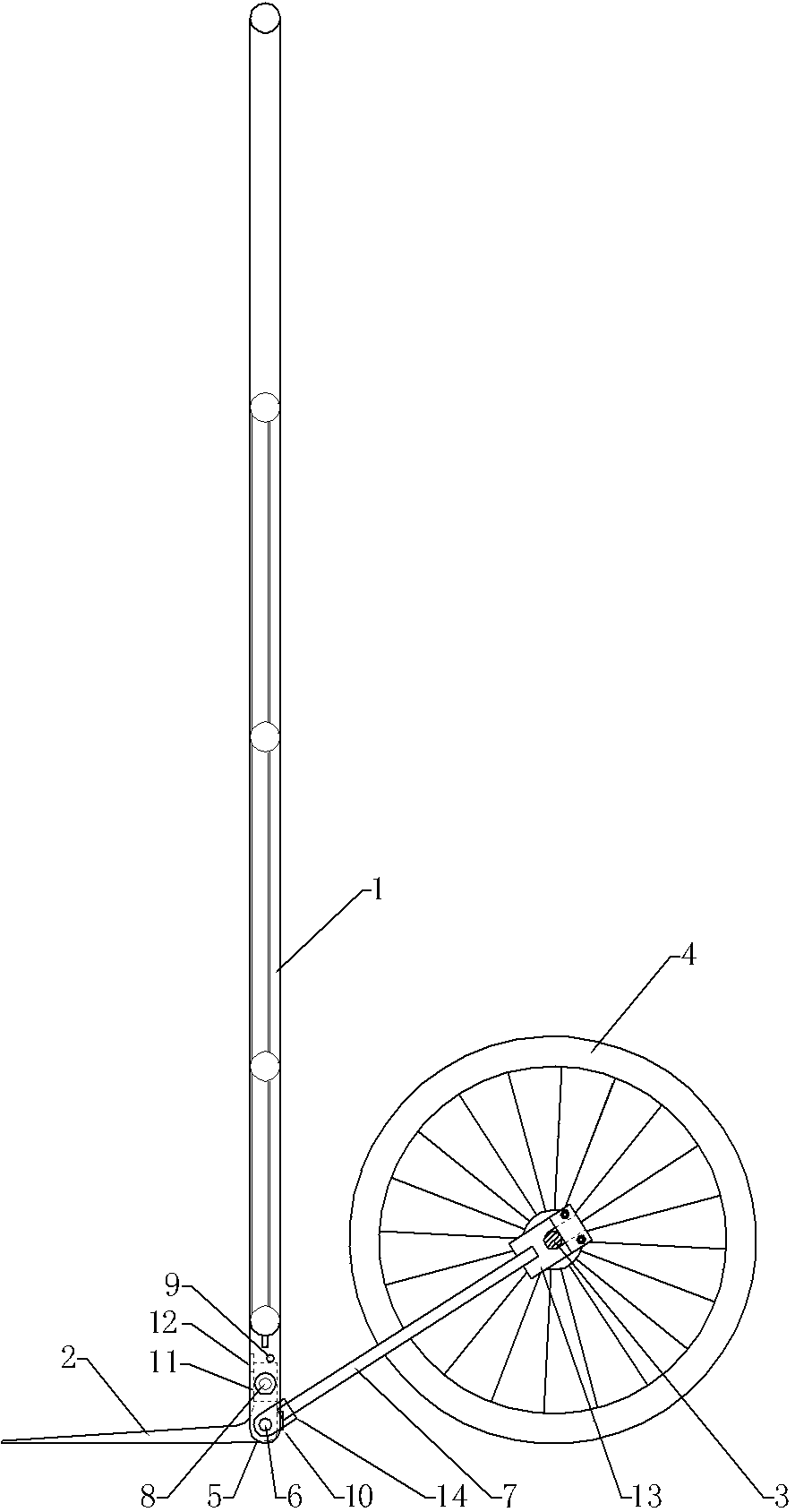

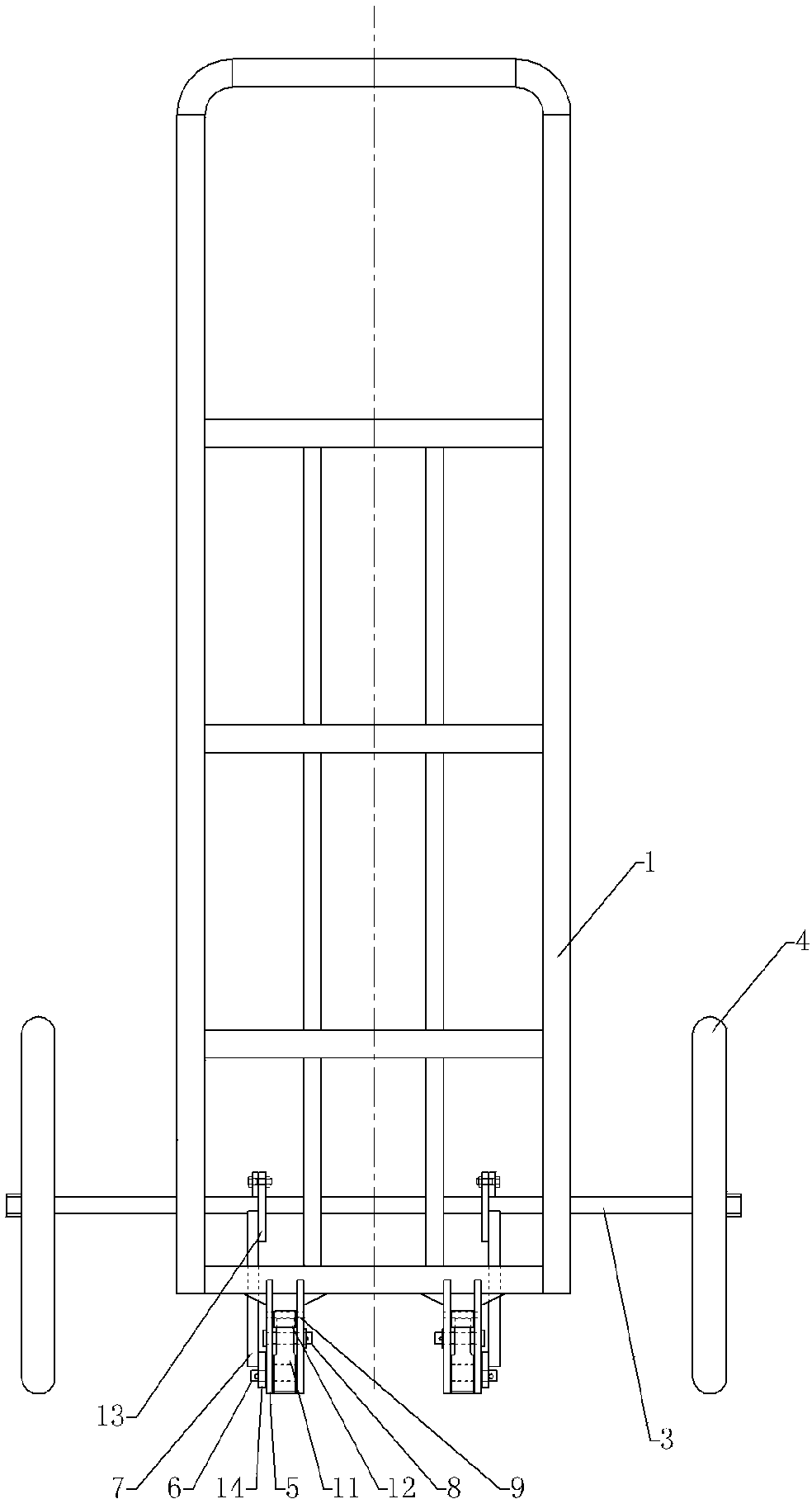

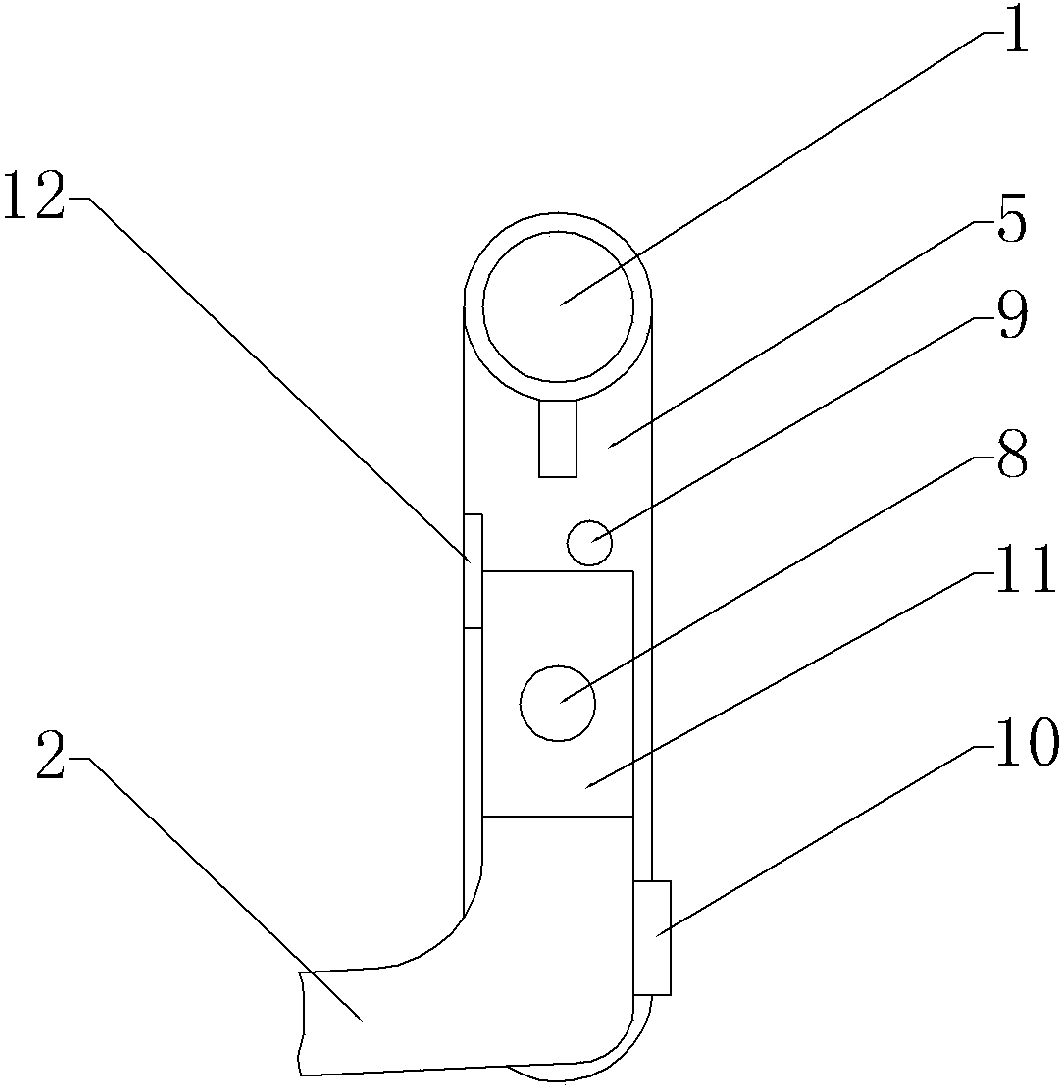

[0030] The bagged material stacking of embodiment 1, unstacking transfer vehicle such as figure 1 , 2 Shown in and 3, comprise vehicle frame 1, flashboard 2, wheel connecting rod 7 and two wheels 4 that are connected by axle 3, the lower end of described vehicle frame 1 and one end of flashboard 2 are connected through the rotation of flashboard turning pin 8 One end of the wheel connecting rod 7 is rotatably connected to the lower end of the vehicle frame 1 through the connecting rod revolving pin 6, and the other end is rotatably connected to the wheel shaft 3. Parallel; the vehicle frame 1 has two working positions, an overturning loading space at an acute angle with the inserting plate 2 and a transporting position at a 90° angle, and a vehicle frame 1 is arranged between the vehicle frame 1 and the inserting plate 2 Rotate counterclockwise with the pin 8 as the axis to locate the first limit stop structure of the overturned loading space and the frame 1 rotate clockwise ...

Embodiment 2

[0032] The bagged material stacking of embodiment 2, destacking transfer vehicle, such as Figure 4 As shown, the difference from Embodiment 1 is that: the side of the vehicle frame 1 facing the wheels 4 is provided with a frame support 15 fixedly connected with the vehicle frame 1 for making the vehicle frame 1 bear on the wheel axle 3 . The support of the frame lifts the frame to a certain height relative to the wheel axle, so that the user does not have to bend over too much when pushing the transfer vehicle, which is easy and labor-saving, and is more ergonomically designed.

[0033] The status of the bagged material stacking and destacking transfer vehicle in this embodiment when it is used for destacking and loading is as follows Figure 5-12 shown. When loading, such as Figure 5 , 6 As shown, set off the transfer vehicle so that the board 2 is placed flat on the ground, and the baffle plate 10 limits the position of the vehicle frame 1. At this time, the angle betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com