Dual-ball lollipop machine convenient to assemble and disassemble

A lollipop machine and convenient technology, applied in confectionery, confectionery industry, food science and other directions, can solve the problem of lack of special equipment for the production of double candy head lollipops, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

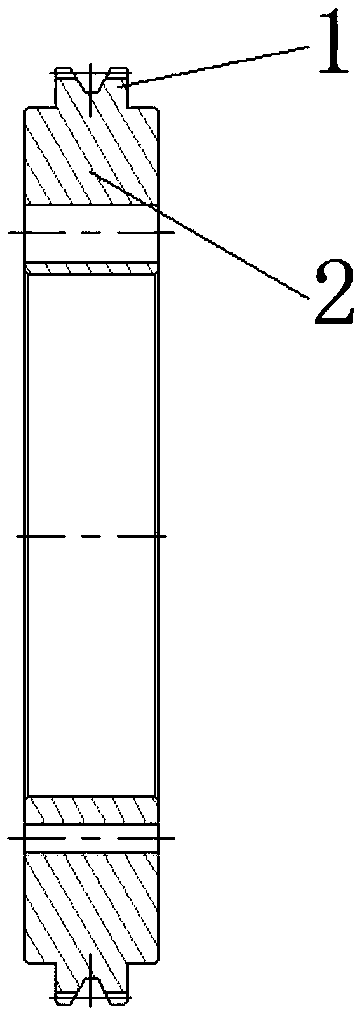

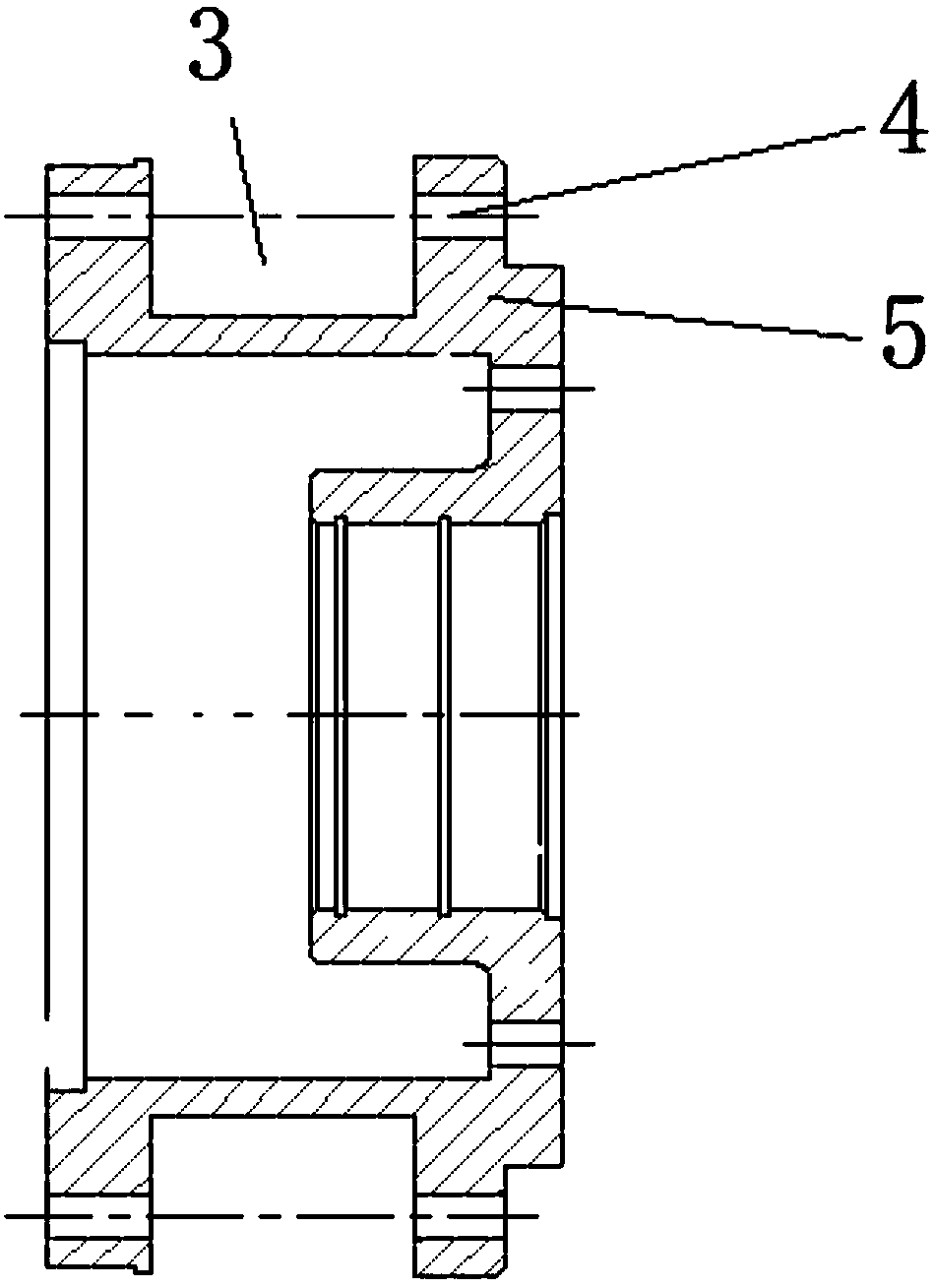

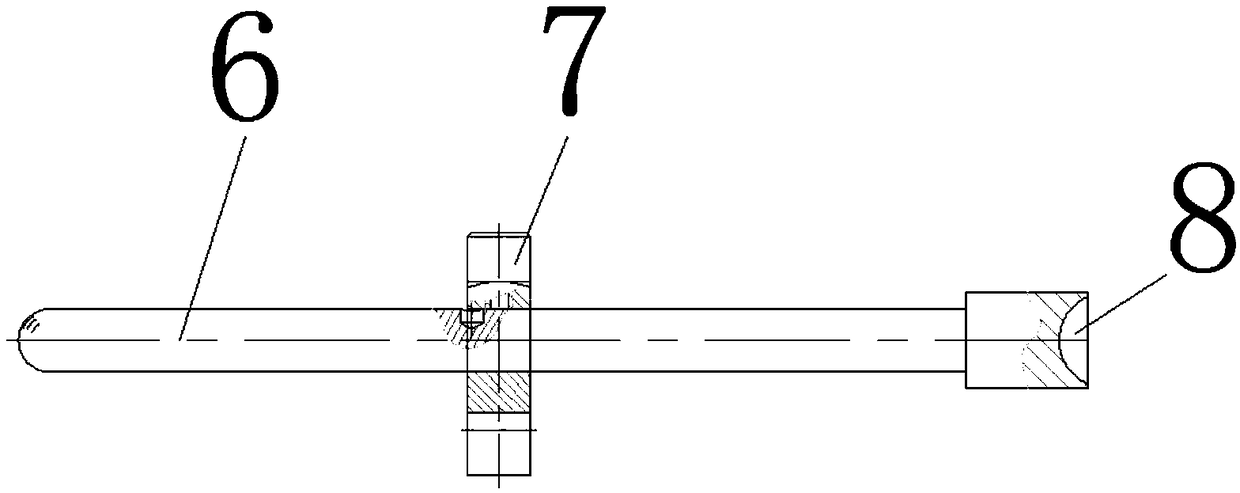

[0063] Example 1: See Figure 1-17 , the present invention provides a technical solution: a double-ball lollipop machine that is easy to install and disassemble, including a mounting frame, a main shaft 28, a lollipop stick conveyor 2, a left lollipop head forming assembly and a right lollipop head forming assembly;

[0064] The mounting frame includes a left mounting frame, a right mounting frame, a base, a first mounting shaft 33 and a second mounting shaft 32; the base is fixed on the support table, and the left mounting frame is installed on the left side of the base. side, the right mounting frame is installed on the right side of the base; from front to back, the two ends of the first mounting shaft 33 and the second mounting shaft 32 are respectively mounted on the left mounting frame and the right mounting frame;

[0065] The two ends of the main shaft 28 are installed on the left mounting frame and the right mounting frame respectively, and are arranged horizontally; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com