Cooking utensil for automatically washing rice

A technology for cooking utensils and rice washing, which is applied to the structure of cooking utensils, cooking utensils, household utensils, etc., can solve the problems of cleaning dead corners, breeding bacteria, and unsatisfactory rice cleaning, and achieves good cleaning effect, cleaning, and avoiding flushing efficiency. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

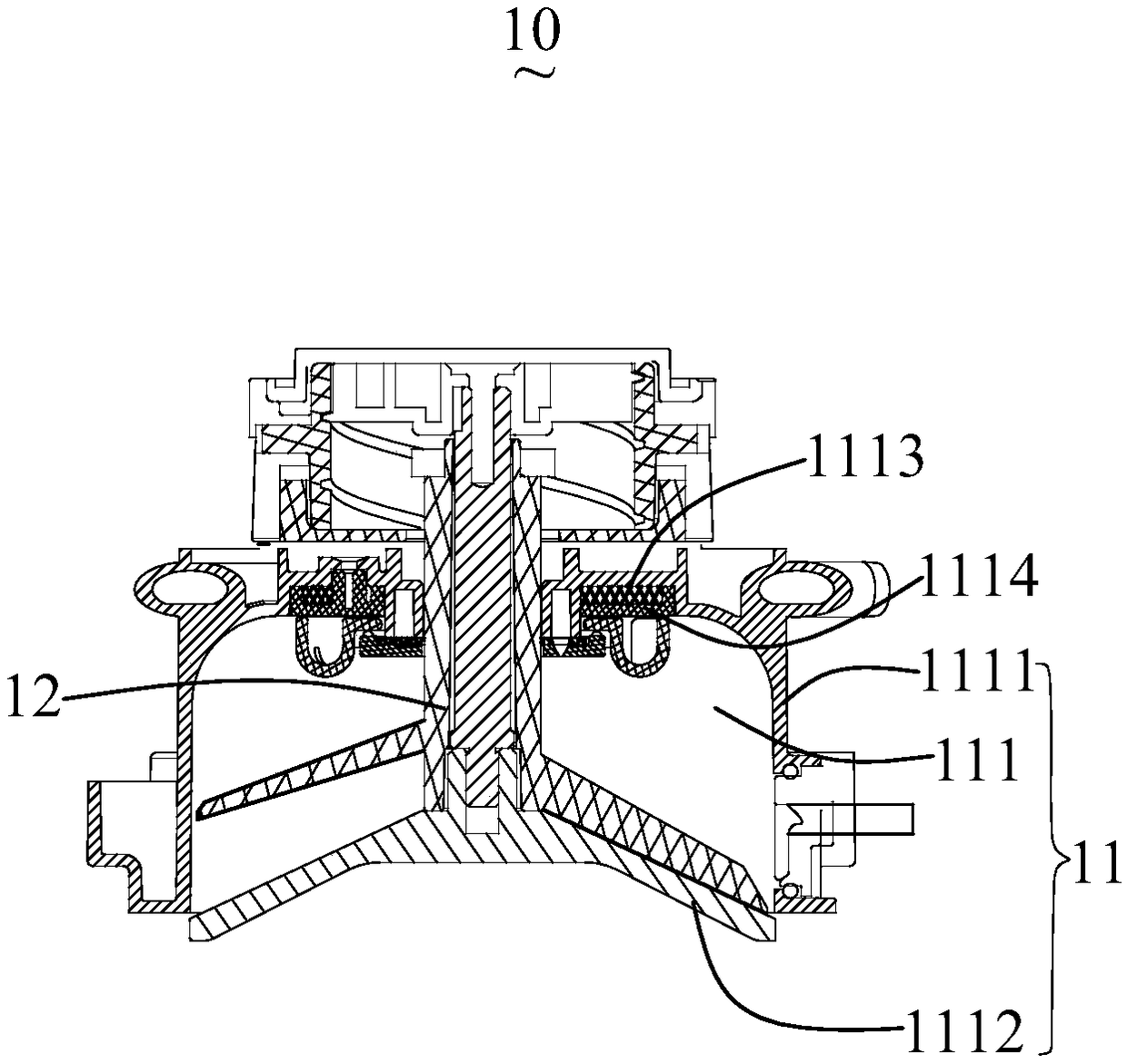

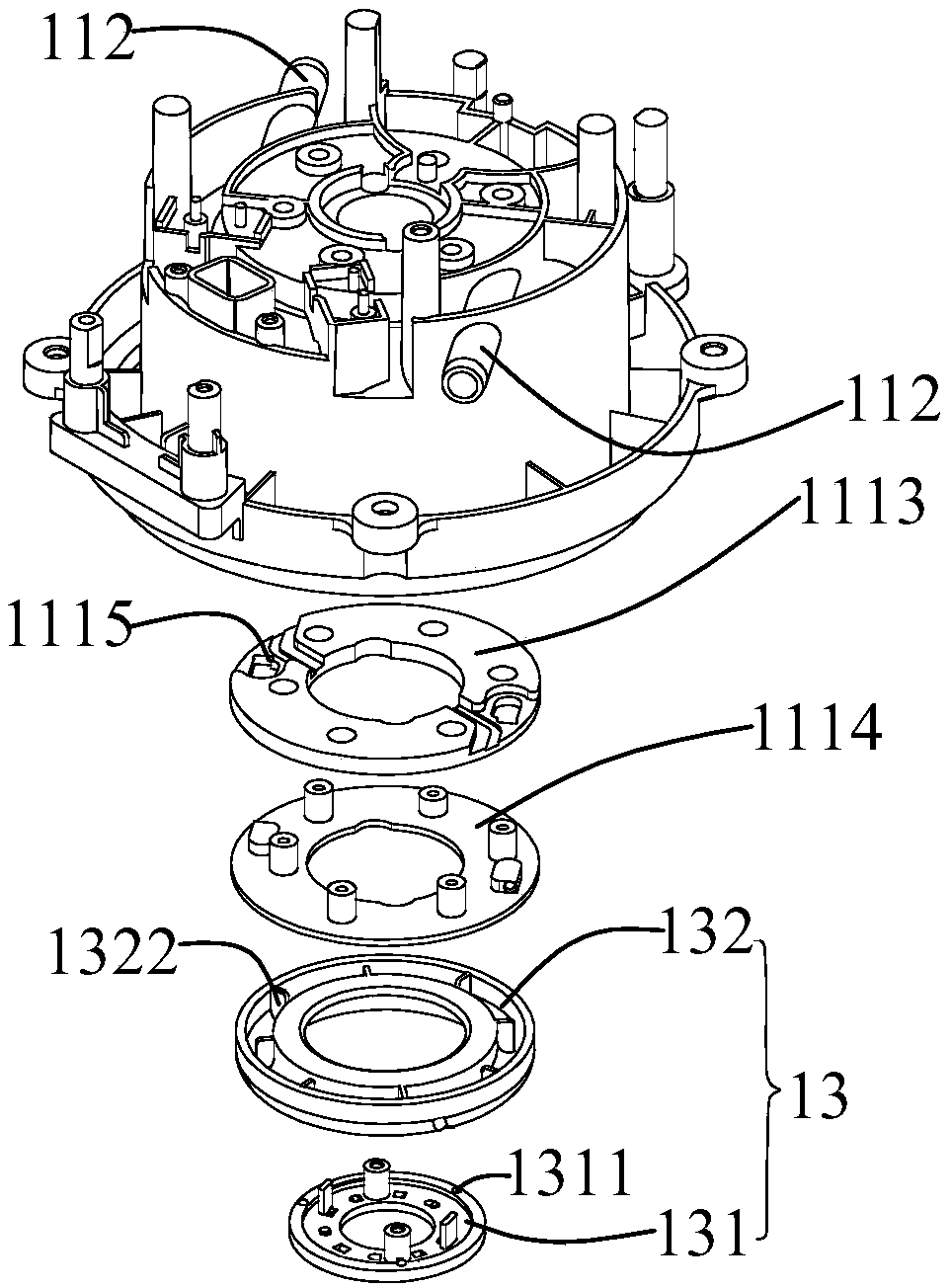

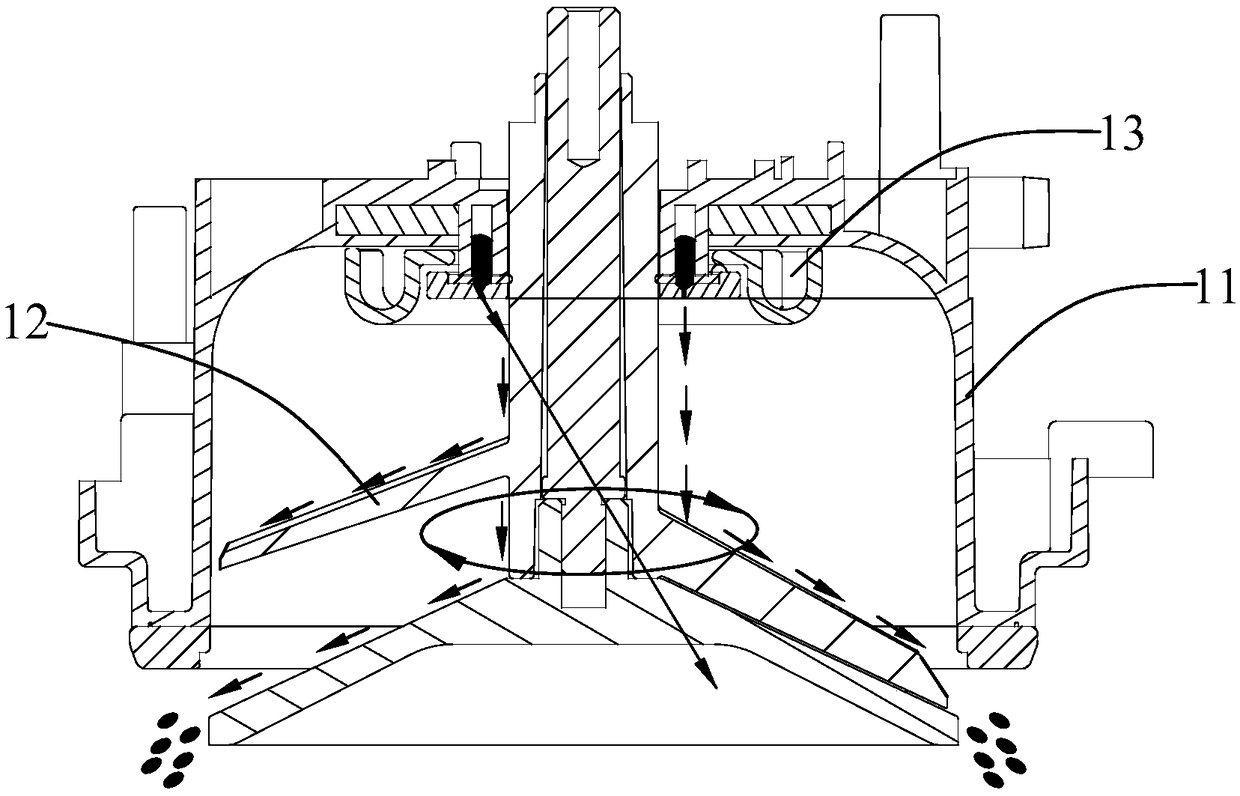

[0032] Please also refer to figure 1 , figure 2 and image 3 Shown is the first preferred embodiment of the automatic rice washing cooking appliance of the present invention, the automatic rice washing cooking appliance 10 includes a rice washing bin 11 and a stirring device 12 for stirring rice, and a cleaning chamber is arranged in the rice washing bin 11 111, the stirring device 12 extends into the cleaning chamber 111 from the top of the rice washing bin 11, the upper part of the rice washing bin 11 is provided with a water supply port 112, and the top of the cleaning chamber 111 is provided with a cleaning assembly 13, and the water supply port 112 is The cleaning assembly 12 supplies water.

[0033] The rice washing bin 11 includes a cavity 1111 with an opening at the bottom, and a bottom cover 1112 for covering the opening. The lifting of the bottom cover 1112 opens the cleaning chamber 111 or closes the cleaning chamber 111 .

[0034] Please also refer to Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com