Device for prolonging pipeline filtering use period in water conservancy project

A technology for water conservancy projects and pipelines, applied in the direction of filtration and separation, membrane filters, fixed filter elements, etc., can solve the problems of inconvenient cleaning of garbage, poor filtering effect, time-consuming and laborious, etc., to reduce the frequency of cleaning or replacement, and reduce direct Shock, improve the effect of filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

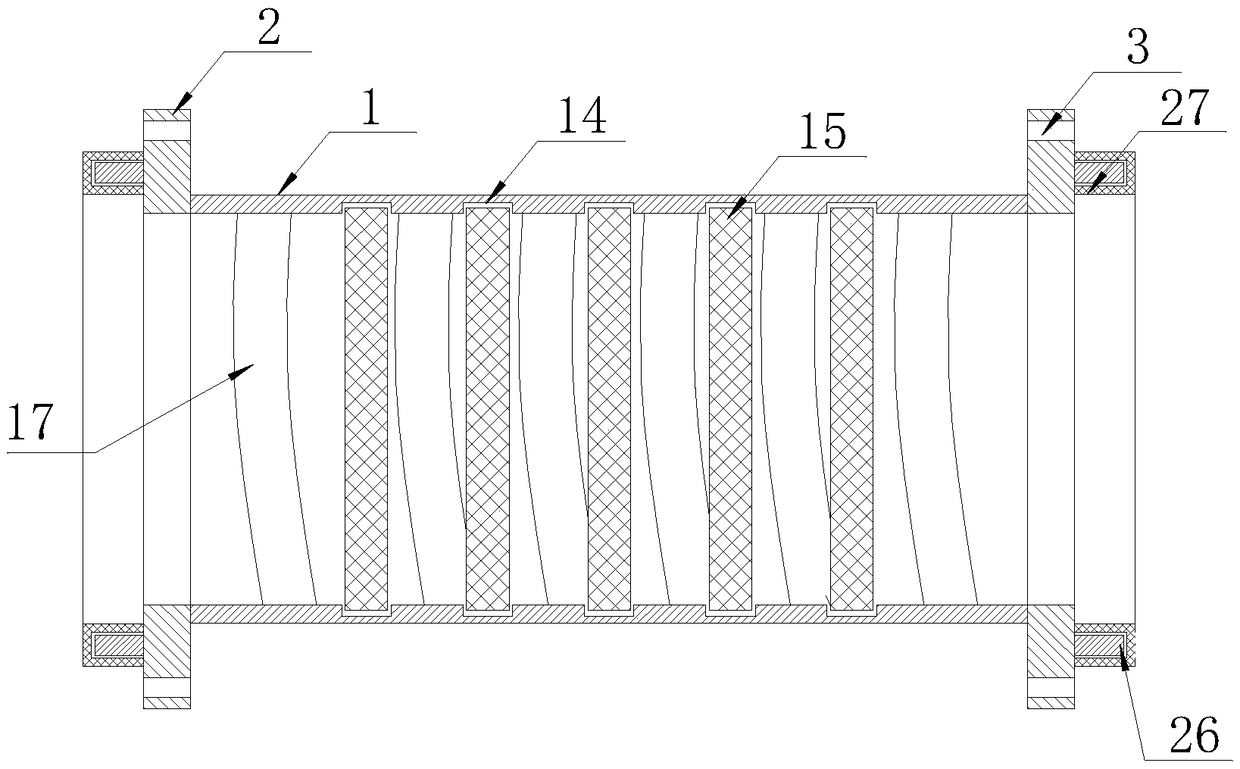

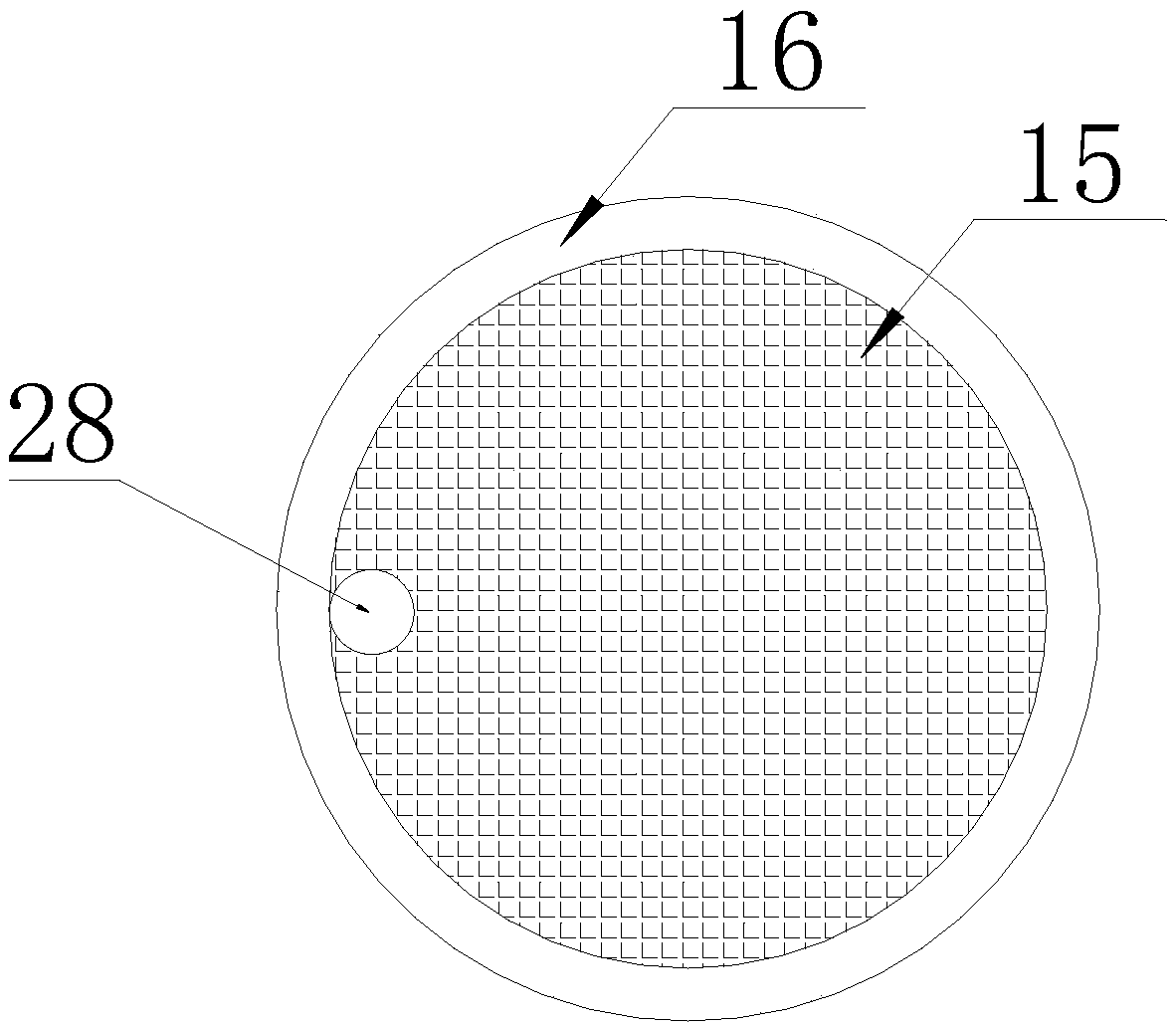

[0036] The present invention provides a filter device for pipeline transportation in water conservancy projects, comprising a filter cavity 1, connecting flanges 2 are arranged at both ends of the filter cavity 1, and positioning Connecting pin holes 3, the filter cavity 1 includes a top cover 101 and a bottom cover 102, both ends of the top cover 101 are fitted with the inner side walls of the connecting flange 2 on the corresponding side, and the two ends of the bottom cover 102 All are fixedly connected with the inner side wall of the connecting flange 2 on the corresponding side, and the inside of the filter chamber 1 is provided with an annular fitting groove 14, and a filter plate 15 is fitted in the annular fitting groove 14, and the edge of the filter plate 15 The position is covered with a sealing rubber ring 16, the inner wall of the filter cavity 1 is provided with a diversion groove 17, the inner side of one end of the bottom cover 102 is provided with a groove 18 a...

Embodiment 2

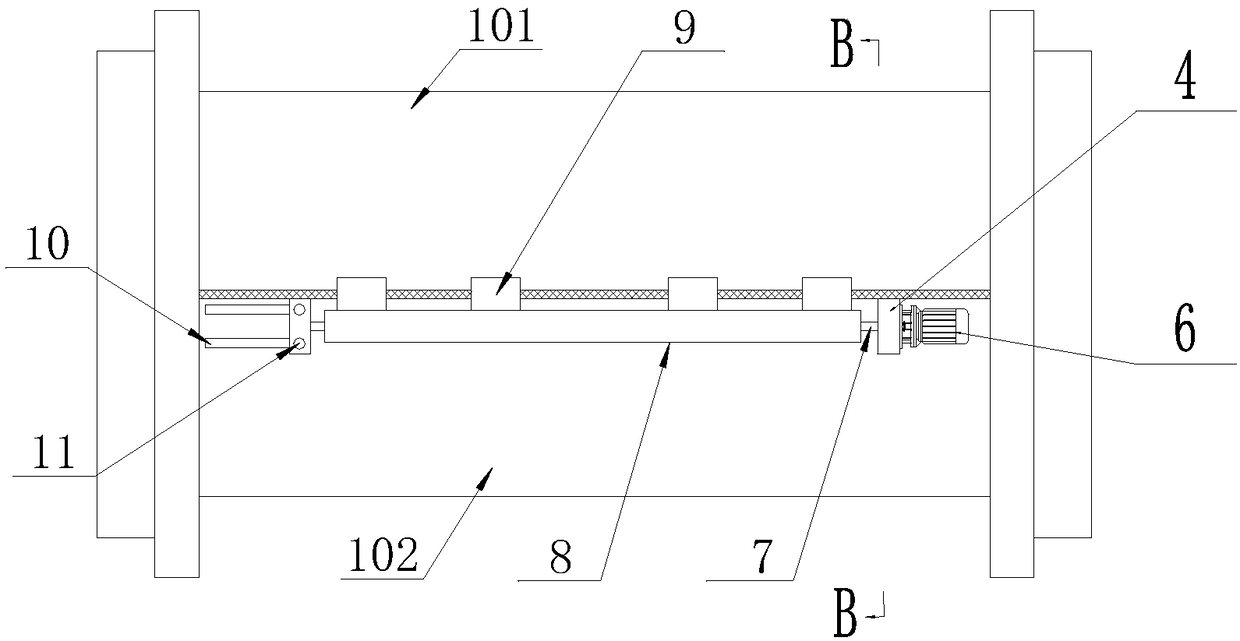

[0042] Further, in the technical solution of Example 1, a slide groove 10 is provided on one end surface of the bottom cover 102, and a threaded hole is provided at the bottom end of the slide groove 10, and the bottom end of one of the first fixing blocks 4 is arranged on In the chute 10, and movably connected with the chute 10, the top of one of the first fixed blocks 4 is provided with a first locking screw hole 11, and the first locking screw hole 11 matches the threaded hole , the outer fixed sleeve of the rotating shaft 7 is provided with a transmission gear 12, the inner wall of the sleeve 8 is equipped with gear teeth 13, the transmission gear 12 is meshed with the gear teeth 13, and both ends of the sleeve 8 are connected to the opposite side. The inner wall of the first fixed block 4 of the filter cavity 1 is attached to the inner wall. When the top cover 101 or the bottom cover 102 of the filter chamber 1 is partially damaged, the connecting flange 2 on the side away...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com