Quick-change type fan-shaped soft claw

A quick-change, soft-claw technology, applied in the field of machining, can solve the problems of not being universal, wasting manpower, easy to produce stress and deformation, etc., achieving the effect of good universal type, fast and convenient clamping, and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

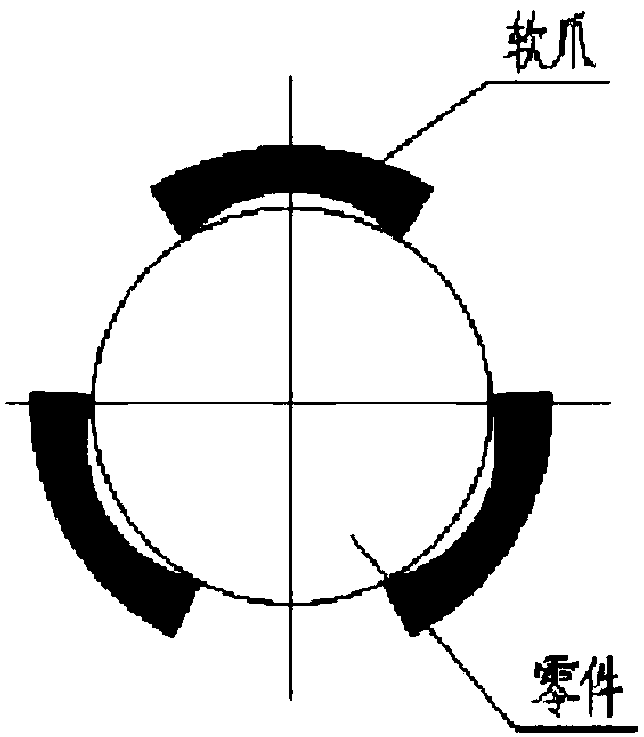

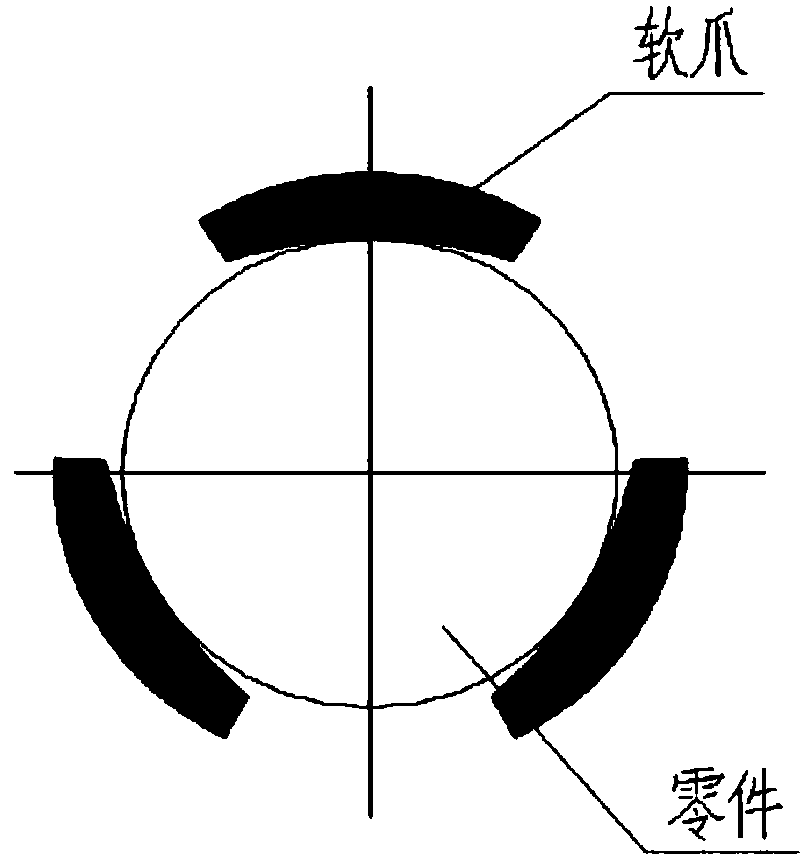

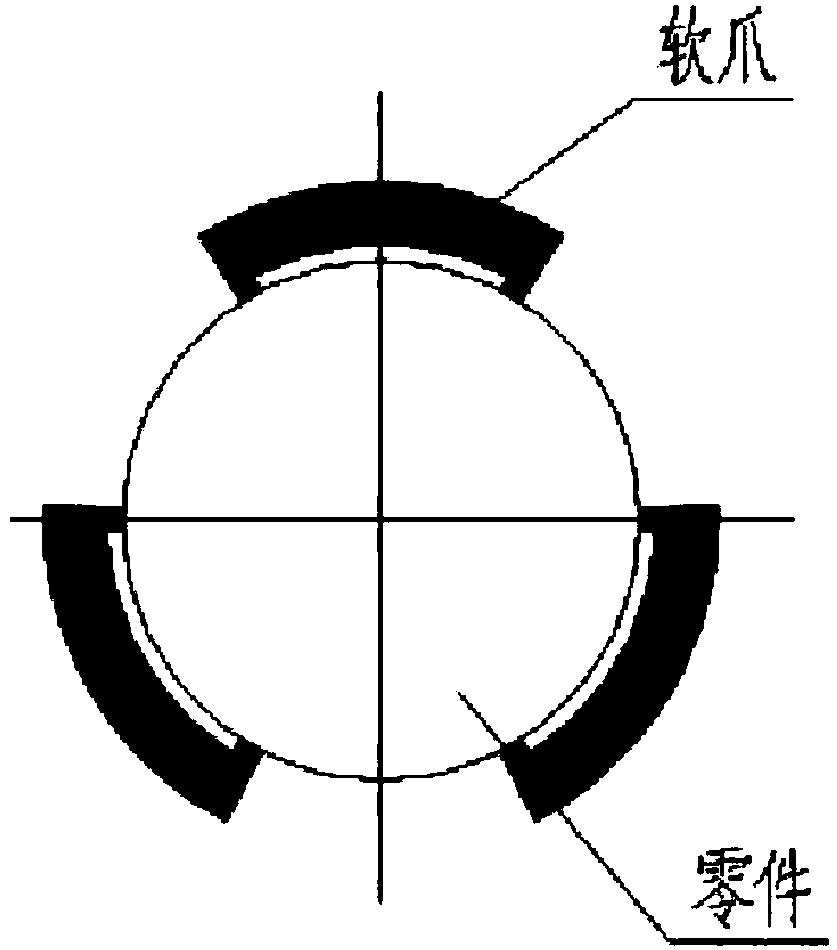

[0019] Because the jaws of the three-jaw chuck have a detachable function. For the multi-variety and small-batch workpieces in the workshop, a machine tool and a three-jaw chuck can be used to design different replaceable soft jaws. When processing different products, the soft jaws can be quickly replaced. At the same time, the designed soft jaws have a large sector of contact, and are also suitable for processing workpieces with insufficient rigidity.

[0020] see Figure 4 , Figure 5 , the device of the present invention is a quick-change fan-shaped soft claw, and its components are a claw 1, an upper connector 2, a self-made soft claw 3, and a connecting screw 4. Among them, the jaw 1 is modified from the traditional three jaws, and the part that can be connected with the flat thread of the chuck is reserved. After the upper connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com