Waste water recycling power-generation device

A wastewater treatment and power generation device technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as energy waste, achieve long service life, and facilitate disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

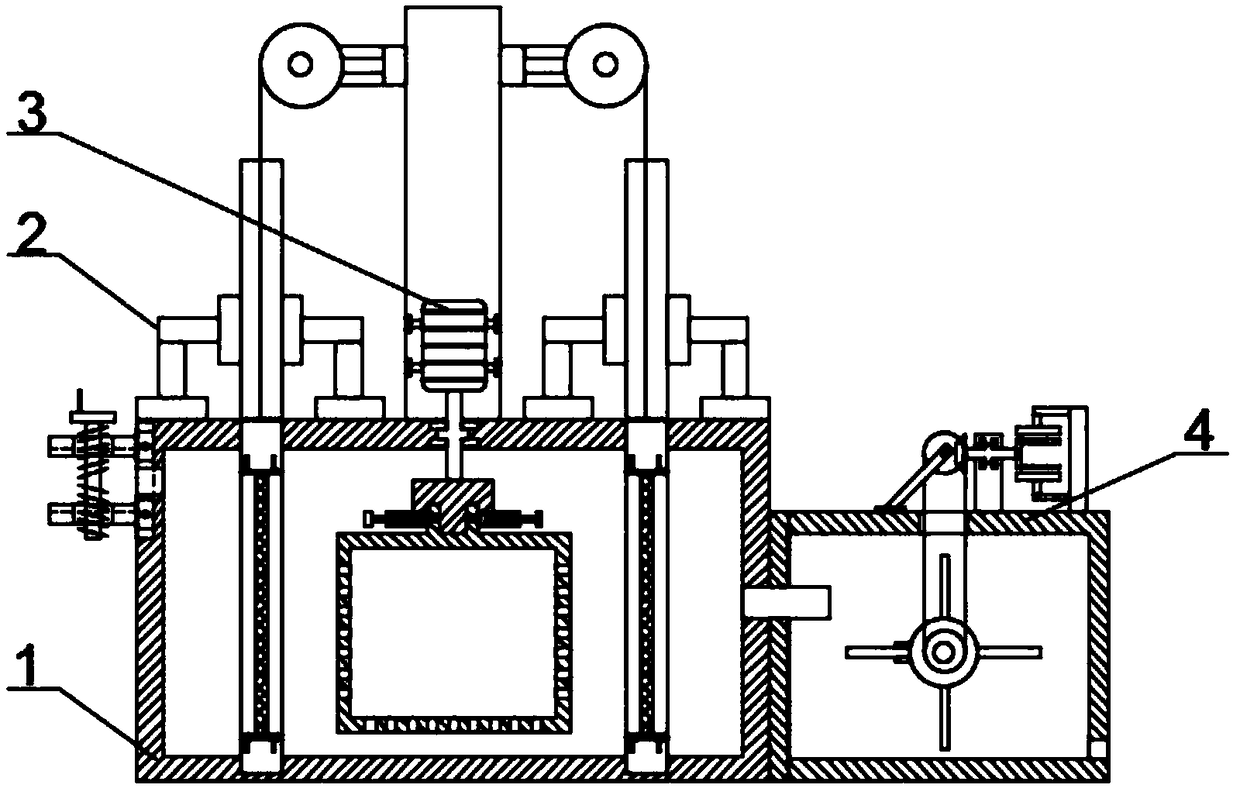

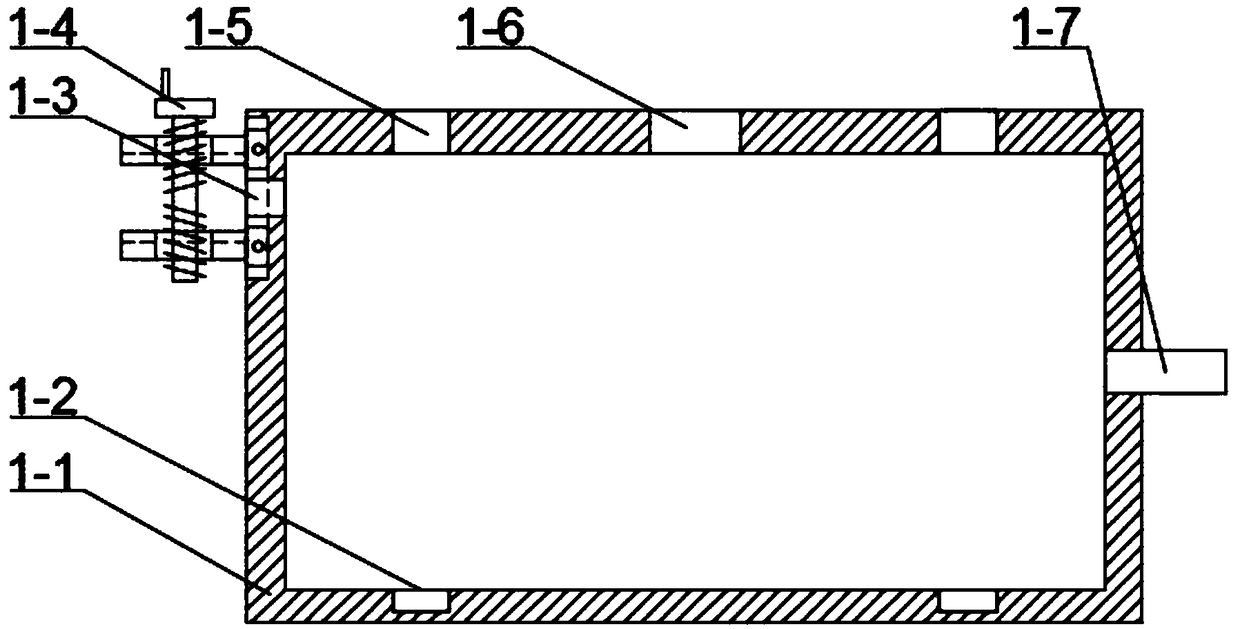

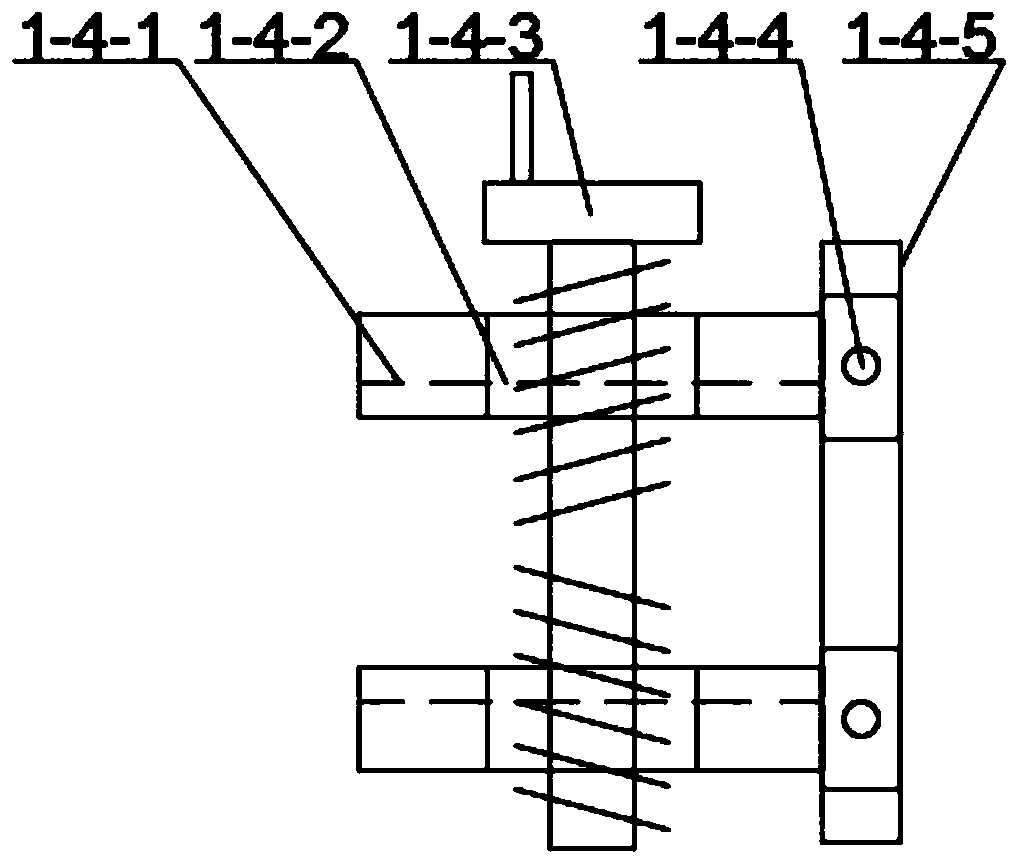

[0036] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 To illustrate this embodiment, the present invention relates to a wastewater utilization device, more specifically a wastewater treatment and reuse power generation device, including a wastewater treatment tank mechanism 1, a lifting filter mechanism 2, a rotating activated carbon box mechanism 3, and a power generation mechanism 4 , the device can lock the water inlet pipe, the device can filter and purify the waste water, the device can pull the filter out of the device for cleaning and replacement, the device can use activated carbon to absorb clean water, the device can disassemble the activated carbon box more conveniently, and the device can generate electricity , the device can guarantee a long service life.

[0037] Wastewater treatment tank mechanism 1 includes water tank body 1-1, lifting filter...

specific Embodiment approach 2

[0049] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 This embodiment will be described, and this embodiment will further describe Embodiment 1. The materials of the water tank body 1-1, the activated carbon tank body 3-1, and the generating tank 4-1 are stainless steel.

specific Embodiment approach 3

[0050] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 This embodiment will be described. This embodiment will further describe the first embodiment. The material of the two-way screw rod 1-4-3-3 is 40Cr.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com