Pressing pressure exchange device

A technology for exchanging devices and pressure, which is applied in the direction of valve devices, functional valve types, engine components, etc., and can solve problems such as short service life, uncontrollable time, and easy damage of solenoid valves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings of the description.

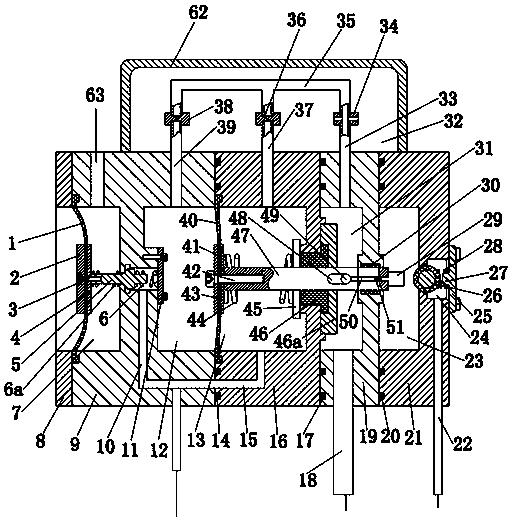

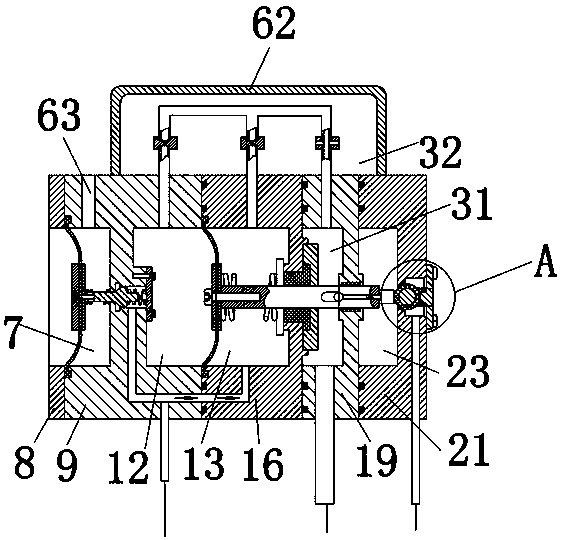

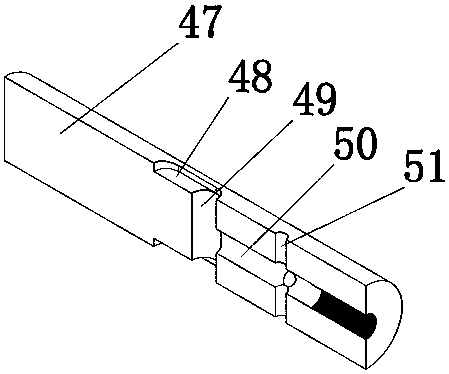

[0016] As shown in the figure, the pressing pressure exchange device is composed of a first housing 8, a second housing 9, a third housing 16, a fourth housing 19, and a fifth housing 21 connected to each other. The outer cover 52 constitutes the buffer chamber 32; the first elastic sheet 1 is arranged between the first housing 8 and the second housing 9 to form the first cavity 7, and the second housing 9 is provided with a micro-opening valve core 5, which is micro-opened. The left end of the valve core 5 is fixedly connected with the first elastic piece 1; the second elastic piece 40 is arranged between the second housing 9 and the third housing 16 to form the second cavity 12, the third cavity 13, and the third housing 16 The air outlet rod 47 is arranged on its left and right sealing and sliding cooperation, and the left end of the air outlet ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com