Powerful washing machine for outer sheath yarn of insulating cable

A technology of outer sheath and cleaning machine, which is applied in liquid/gas/steam yarn/filament processing, textile and papermaking, liquid/gas/steam textile material processing, etc., and can solve problems affecting product quality, pollution, time-consuming, etc. , to achieve the effect of saving cleaning time and manpower consumption, convenient replacement and thorough discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The implementation of this patent will be described in further detail below with reference to the accompanying drawings. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of this patent.

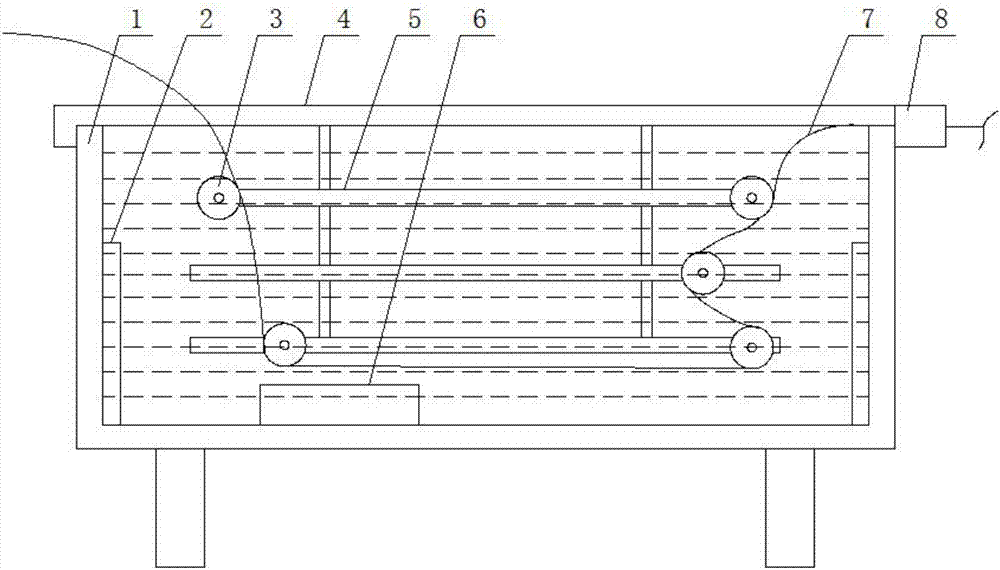

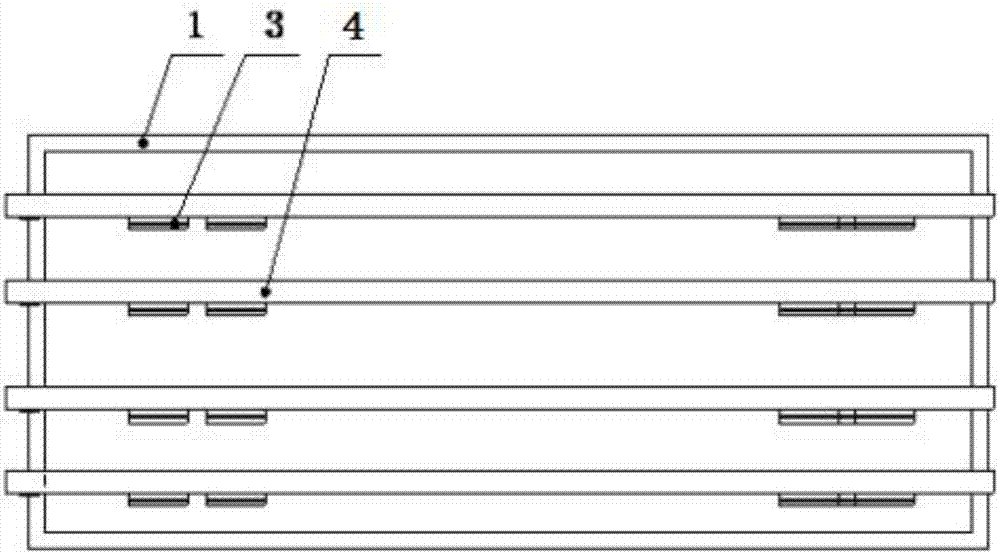

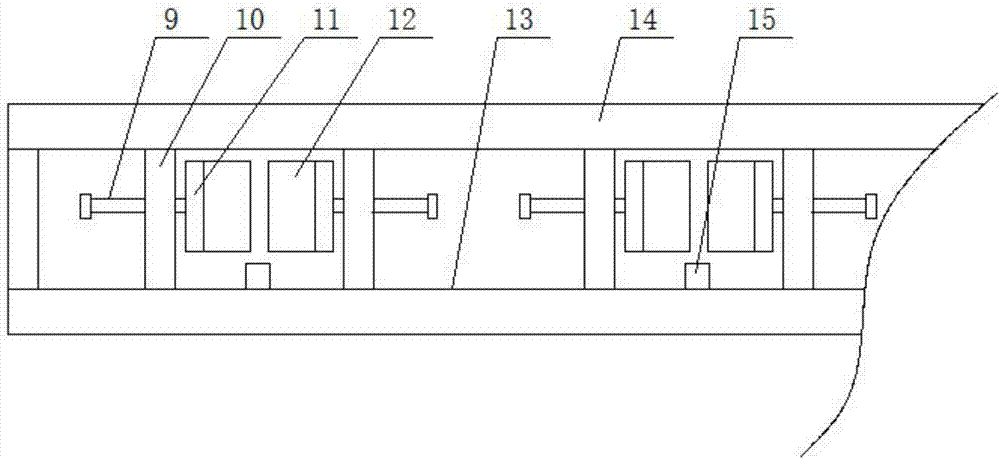

[0020] A powerful cleaning machine for the outer sheath of insulated cables, the innovation of which is that it consists of a mounting frame, a cleaning water tank 1, a cleaning bracket 4, a roller frame 5, a guide roller group 3, a cleaning brush cover, an ultrasonic generator 6, The electric heating tube 2 and the wiping and blowing mechanism 8 are formed. A cleaning water tank is installed on the installation frame, and cleaning brackets are arranged at intervals on the upper end of the cleaning water tank. A roller frame is fixed at the lower part of each cleaning bracket. A longitudinally arranged guide roller group is installed on one side and both ends of the guide roller group, and each roller of the guide roller group is cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com