Super-simple blowing-carding technology and device thereof

A simple and simple blowing-carding technology, applied in the field of ultra-simple blowing-carding process and its devices, can solve the problems of unsatisfactory variety changes, small order production, long process, high output, etc., to shorten the circulation time and reduce losses , the effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

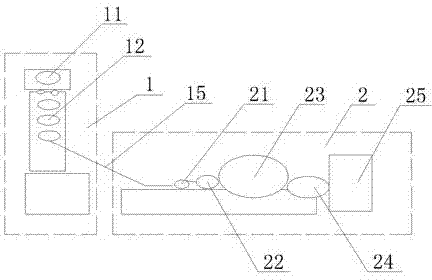

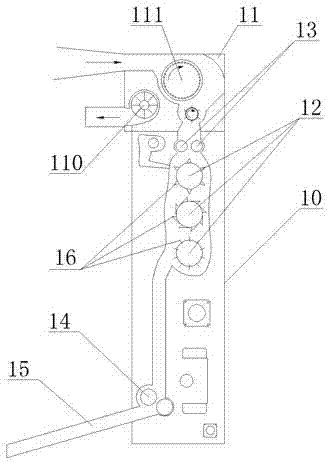

[0026] Such as figure 1 , figure 2 As shown, an ultra-simple blowing and carding device of the present invention comprises a combined multifunctional cotton box 1 and a high-yield carding machine 2.

[0027] The combined multi-functional cotton box 1 includes a box body 10, and on the top of the box body 10 is a condensing box 11. The condensing box 11 includes a fan 110, an opening guide roller 111, and an incremental opening beater 12 is arranged on the side of the condensing box 11. Below, the incremental opening and loosening beaters 12 are connected to the condensing cotton box 11 through the cotton feeding roller 13. The incremental opening and loosening beaters 12 include three groups of opening and loosening beaters arranged in sequence in the box 10, and the cotton feeding rollers are connected to the bottom of the incremental opening and loosening beaters 12. 14. A slant plate 15 is provided at the feeding roller 14, and the slant plate 15 is used to connect the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com