Rod bundle channel visualization experiment body suitable for heating boiling conditions

A technology of rod bundle channel and body, which is applied in the field of rod bundle channel visualization experiment body, can solve the problem of not being able to obtain the details of fuel assembly flow and heat transfer behavior, and achieve the effects of improving the visualization range, low price, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0025] The present invention provides a rod bundle channel visualization experiment body for heating and boiling conditions, which realizes the perfect combination of traditional heat transfer characteristic measurement and visualized advanced measurement means, and can be used for the temperature measurement of the inner wall surface of the rod bundle channel and the flow in the rod bundle channel Visual measurement of heat transfer behavior; the present invention has a rod bundle channel visualization experiment body, which has a simple structure, low price, and a wide range of research conditions covering single-phase and boiling two-phase, and can be used to measure flow and heat transfer characteristics of rod bundle channels under complex conditions.

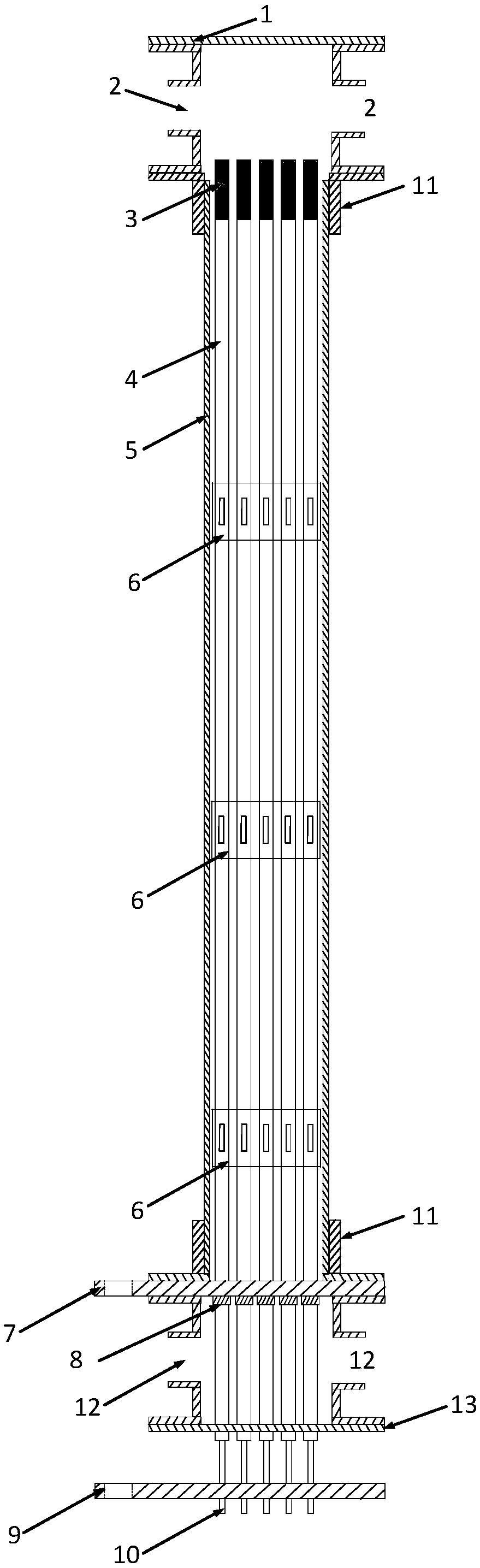

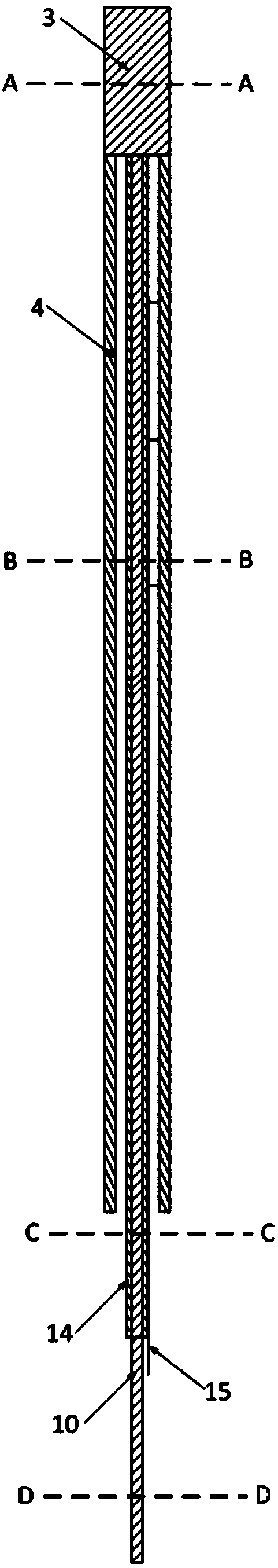

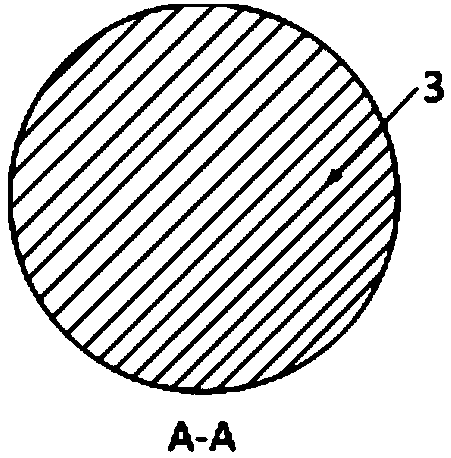

[0026] The experimental body of the present invention mainly includes a square...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com