An overpressure early warning device for rubber hose vulcanization exhaust gas discharge

A technology of exhaust gas emission and early warning device, applied in the direction of coating, etc., can solve problems such as joint loosening, safety hazards, pipeline rupture, etc., and achieve good pressure resistance, expand the scope, and reduce safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

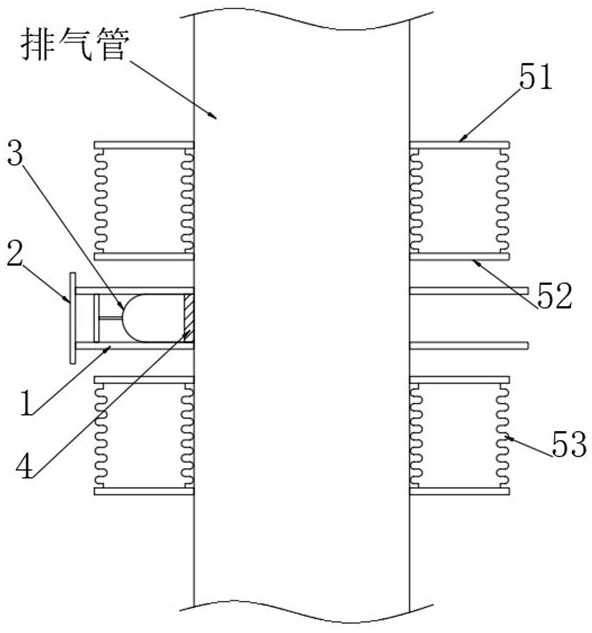

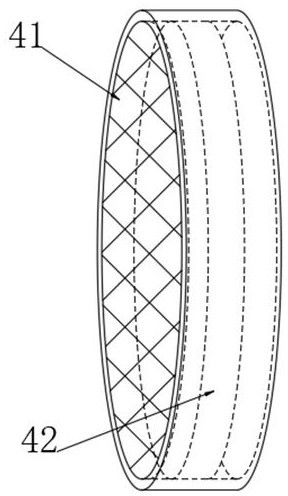

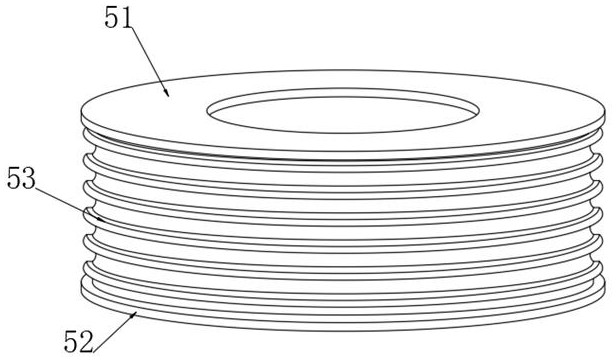

[0045] see figure 1 , an overpressure early warning device for rubber hose vulcanization exhaust gas discharge, comprising two electromagnets 1 fixedly connected outside the exhaust pipe, an air control bag 3 is arranged between the two electromagnets 1, and the inner and outer surfaces of the air control bag 3 are coated Equipped with LINE-X coating, the air control bag 3 has good compressive and tensile properties, so that it is not easy to be damaged under the action of exhaust gas, and the air control bag 3 is embedded with a special fiber weaving. The sealing material of the air control bag 3 is made of the sealing material of the net, which effectively improves the strength of the air control bag 3, and the air control bag 3 is in a relaxed state. The detection port, the over-crushing ring 4 is fixedly connected with the detection port, the end of the air control bag 3 away from the exhaust pipe is fixedly connected with a touch plate, the touch plate is interference fit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com