Waterproof connector and production method thereof

A waterproof connector and main body technology, which is applied in the direction of connection, connection device parts, contact box/base manufacturing, etc., can solve the problems of low production capacity, high cost, increased welding process, etc., to achieve increased production capacity and save equipment Cost, the effect of eliminating the welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

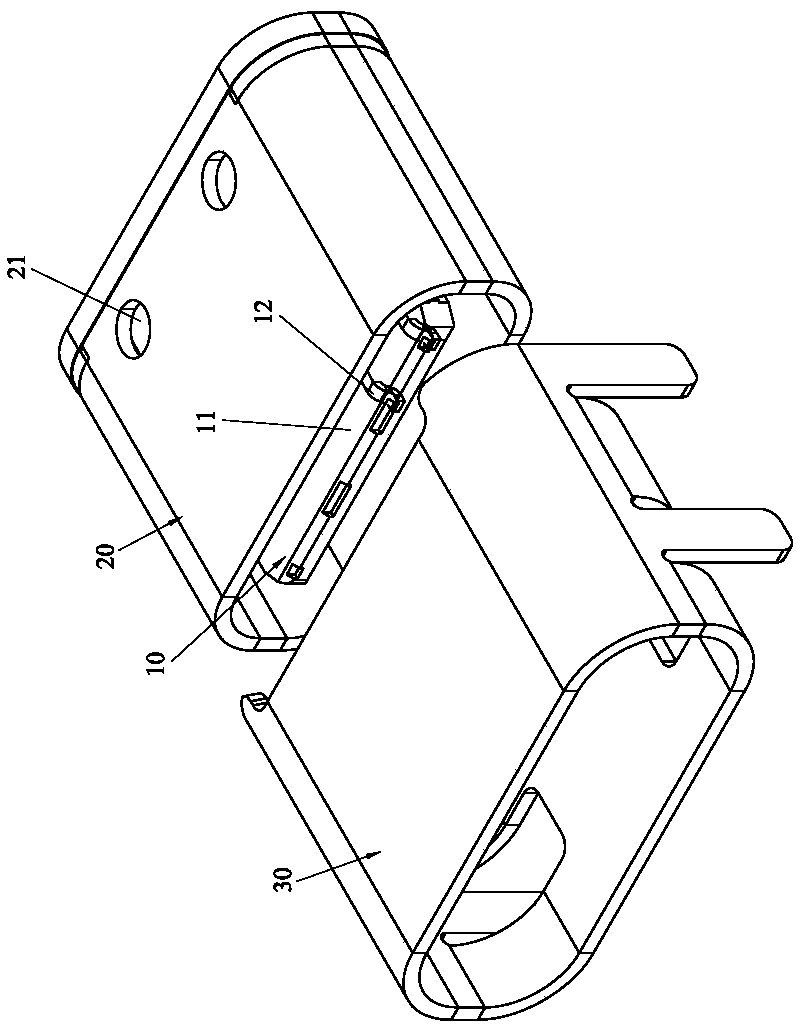

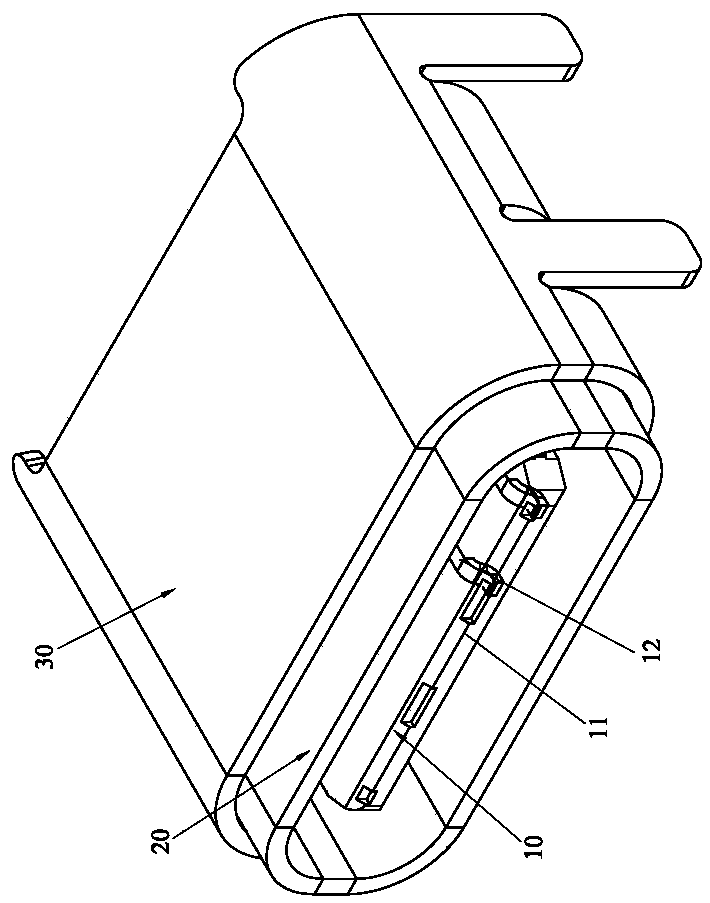

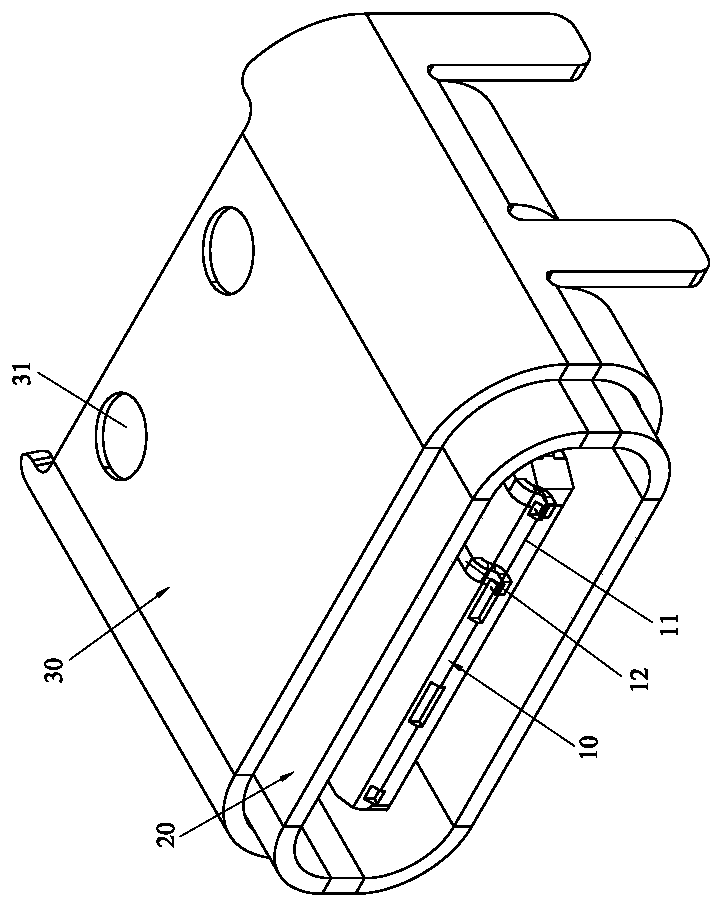

[0027] Please refer to Figure 1 to Figure 3 As shown, it shows the specific structure of the preferred embodiment of the present invention, including the body 10 .

[0028] The body 10 is a TYPE-C body, which includes an insulator 11 and a terminal 12 embedded and fixed on the insulator 11 .

[0029] The main body 10 is provided with a stretched shell 20, the stretched shell 20 is stamped with a blanking hole 21, the stretched shell 20 is stamped with a stamped shell 30, and the stamped shell 30 is stamped with a riveting point 31, The riveting point 31 is riveted and fixed together with the blanking hole 21 .

[0030] In this embodiment, the discharge hole 21 is located at the top of the stretch shell 20, and the discharge hole 21 is located at the top rear end of the stretch shell 20, and at the same time, the discharge hole 21 is arranged at intervals from left to right The number and position of the blanking hole 21 are not limited, and the riveting point 31 is set corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com