Flexible casting sand box device

A sand box and flexible technology, which is applied in the direction of casting molding equipment, mold boxes, manufacturing tools, etc., can solve the problem that the shape and size of the sand box cannot be adjusted flexibly, and achieve the effects of saving time and materials, improving versatility, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

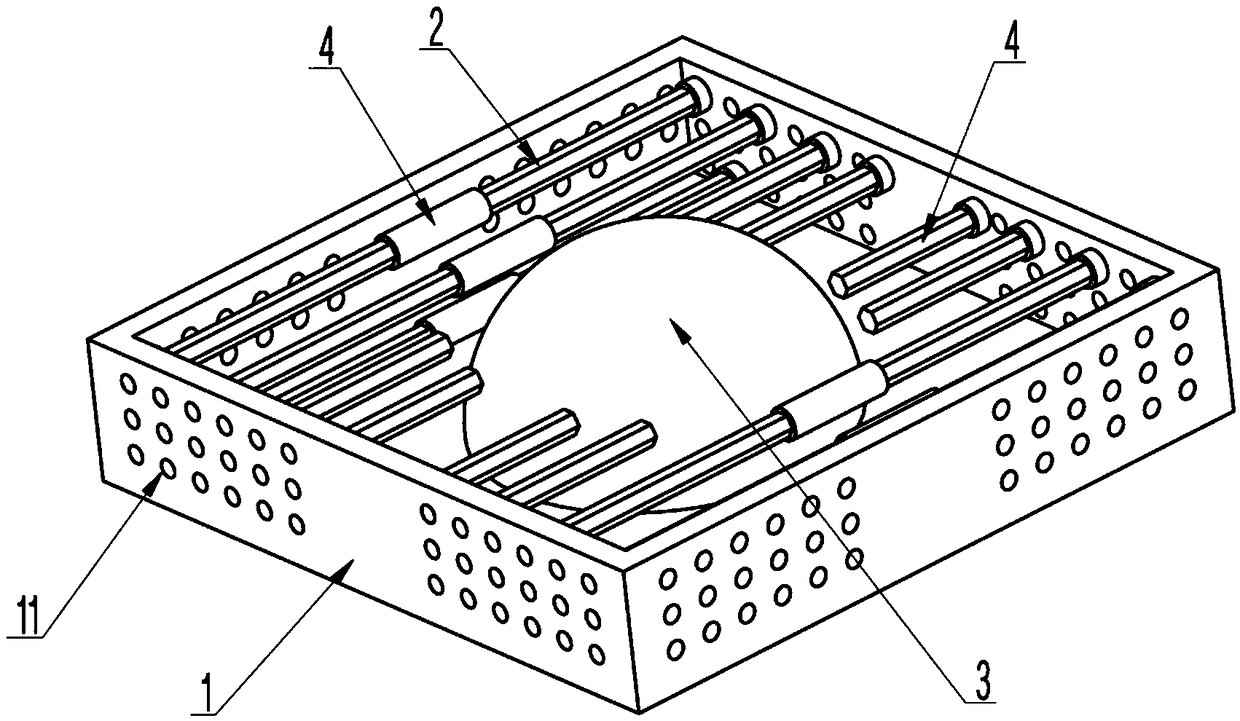

[0024] Such as figure 1 As shown, the present invention provides a flexible casting flask device, which includes a flask 1 and a belt 2 arranged in the flask 1 , the end of the belt 2 is detachably connected to the inner wall of the flask 1 . By setting the box belt 2 and the sand box 1 as a detachable connection, that is, the sand box 1 and the box belt 2 are a split structure, then the sand box 1 can flexibly choose the box belt 2 according to the size of the product, not only can change the box belt 2 size, and the installation position of the box belt 2 can be changed, so even if the size of the sand box 1 does not exactly match the product, it will not affect the casting process, thereby improving the versatility of the sand box 1 and saving repeated sand making Box time and materials, saving costs.

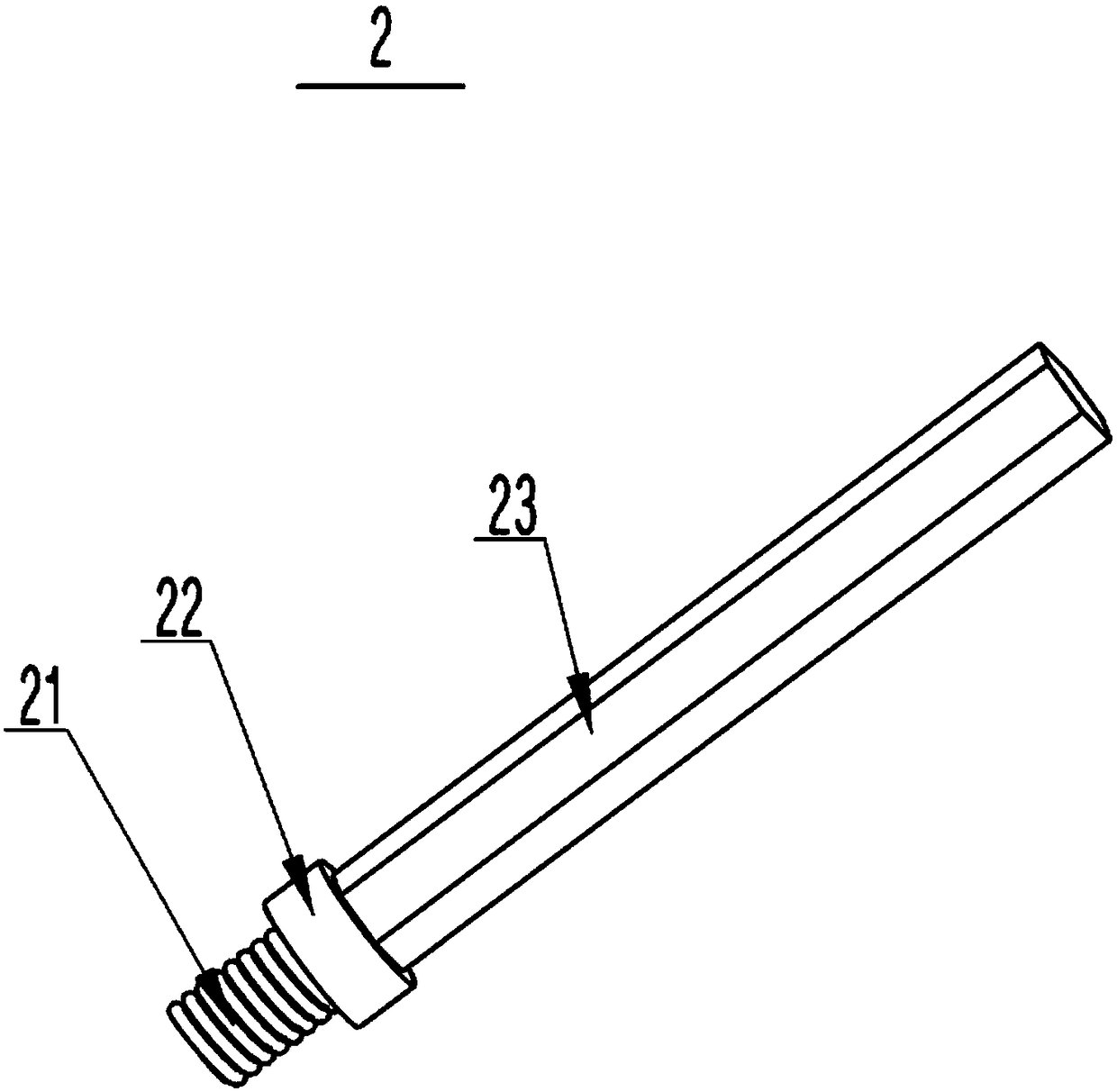

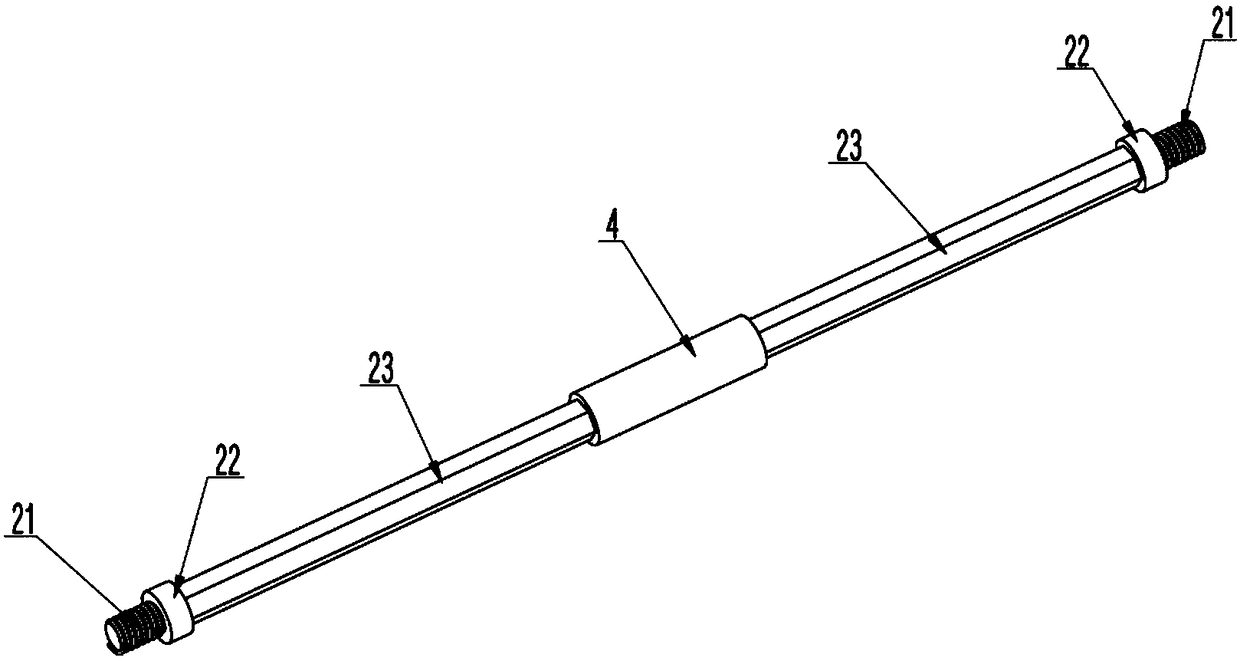

[0025] In one embodiment, such as figure 2 As shown, one end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com