A method for replacing the wire rope of the hoisting mechanism of a tower crane

A lifting mechanism and replacement method technology, which is applied to cranes and other directions, can solve problems such as increased labor intensity, cumbersome procedures, and safety risks, and achieve the effects of reducing workload, avoiding climbing up and down, and improving operational safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

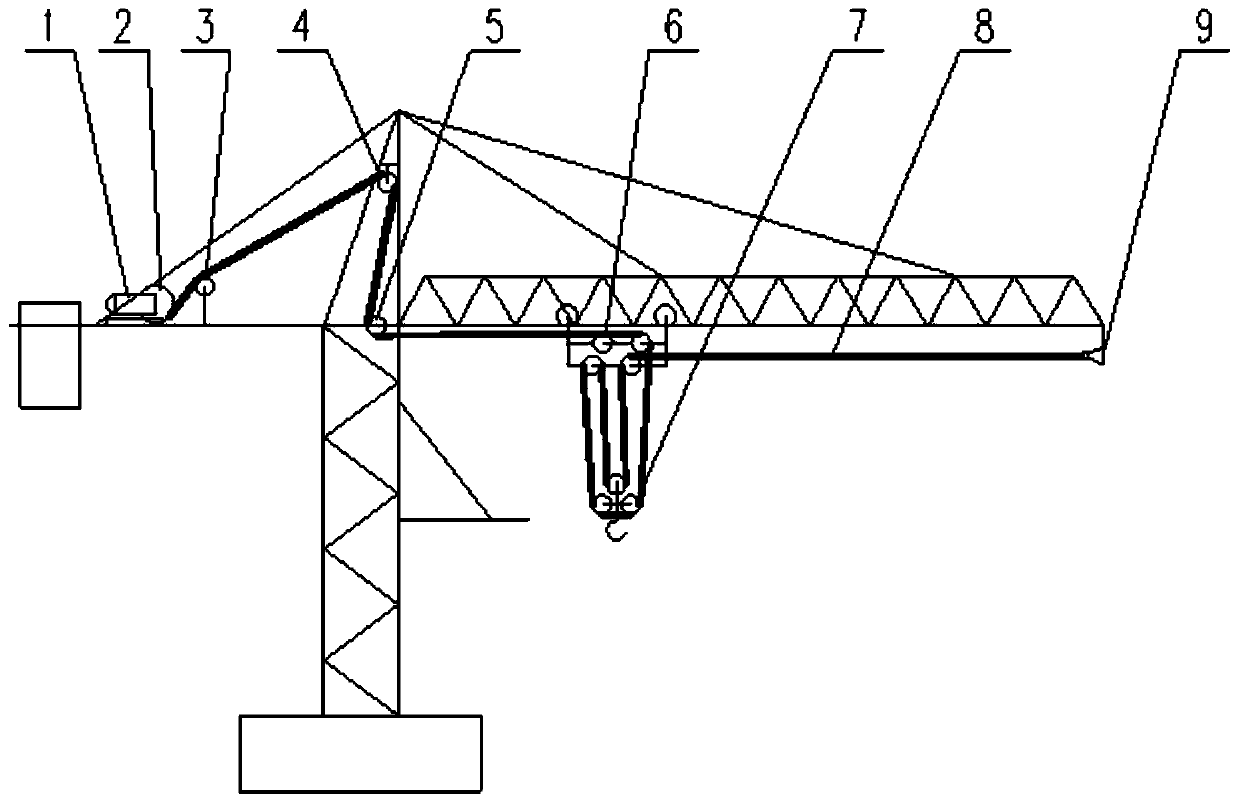

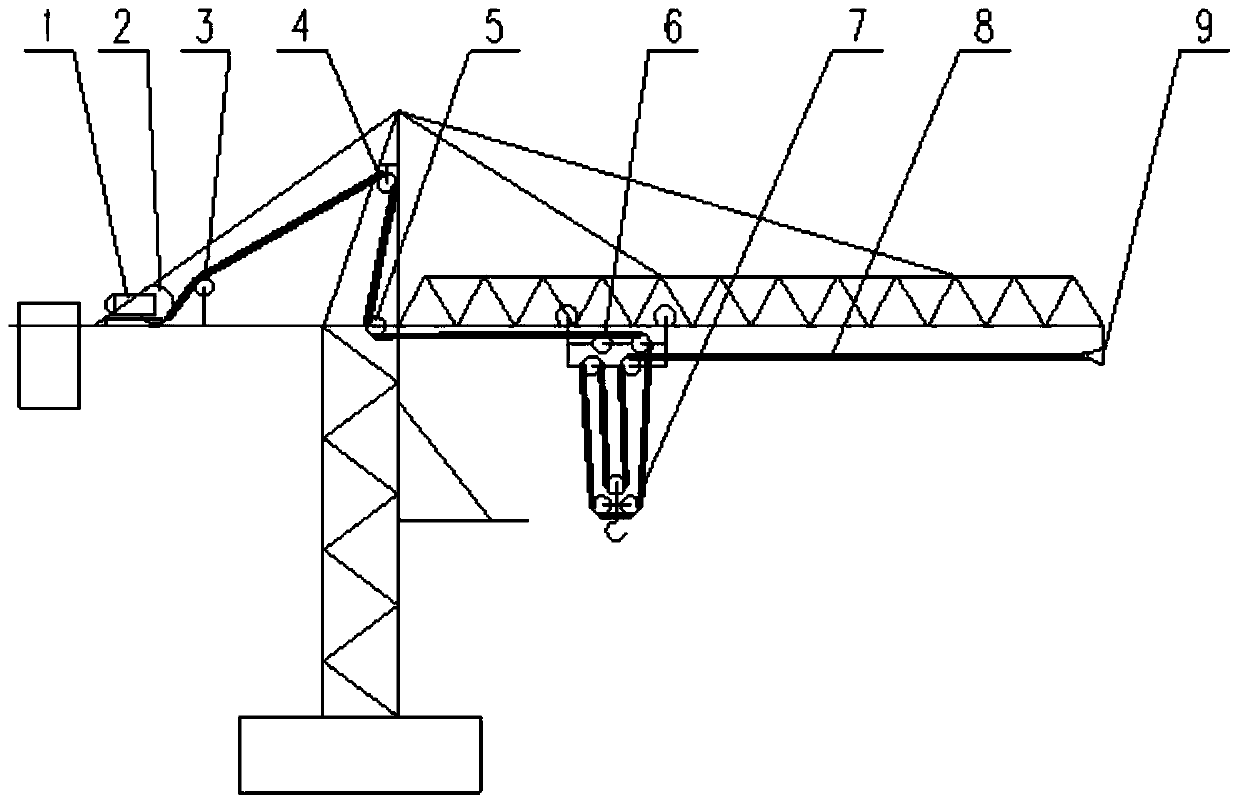

[0019] Such as figure 1 with figure 2 A method for replacing steel wire ropes of a hoisting mechanism of a tower crane includes the following steps:

[0020] 1) Lower the hook 7 to the tower crane platform or the ground, and release the lifting wire rope fixing 9 at the end of the boom;

[0021] 2) Start the hoisting mechanism 1 on the tower crane, release the old steel wire rope 8 on the reel 2, and at the same time, fix the end of the old steel wire rope 8 on the first rope winder 10 for rewinding, until the old steel wire rope 8 is nearly completely released;

[0022] 3) stop releasing the old steel wire rope 8, and remove the fixing of the old steel wire rope 8 on the reel 2, and connect this end with the rope head of the new steel wire rope 11 on the second rope winder 12;

[0023] 4) Continue to rewind the old steel wire rope 8, and u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com