Tool special for picking old pole plates

A special tool and sliding rod technology, which is applied in the field of special tools for picking old rod cards, can solve the problems of time-consuming and laborious, and achieve the effect of ensuring personal safety, avoiding climbing up and down ladders, and shortening operation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

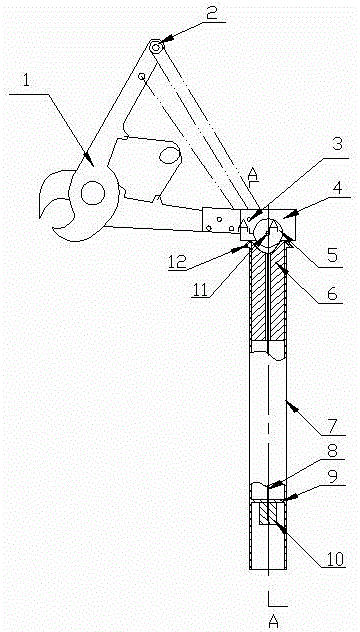

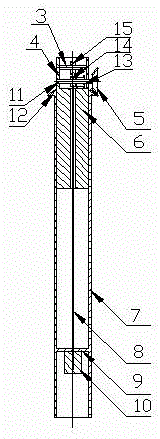

[0012] As shown in the figure, the special tool for extracting the old pole plate includes olecranon 1, the wheel frame 4 is fixed on the lower pliers handle of the oleo pliers 1, and the hollow slide bar 6 is fixed at the lower end of the fixed wheel frame 4. The upper pliers handle of the eagle mouth pliers is rotated and fixed with a pulley 2, the wheel shaft is fixed by rotation on the wheel frame 4 11, on the axle 11 is fixed with big sheave 13 and little sheave 14, on axle The outstretched end of 11 is fixed with bevel gear 5, the wheel shaft is fixed on the wheel frame 4 3, on the axle 3 swivel fixed with pulleys 15. The hollow sliding rod 6 is set in the hollow rod 7, and the upper end of the hollow rod 7 is fixed with a bevel gear 12. There is a partition 9 with holes in the hollow rod 7, and the bevel gear 5 with bevel gear 12 engagement, rope 8 is fixed on the upper pincer handle of olecranon pliers, and the other end of rope 8 walks around large ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com