Lifting support

A lifting bracket and swing rod technology, applied in the field of climbing appliances, can solve the problems of trouble, inability to lift and lower freely, danger, etc., and achieve the effects of convenient use, improved safety factor, and avoidance of up and down climbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

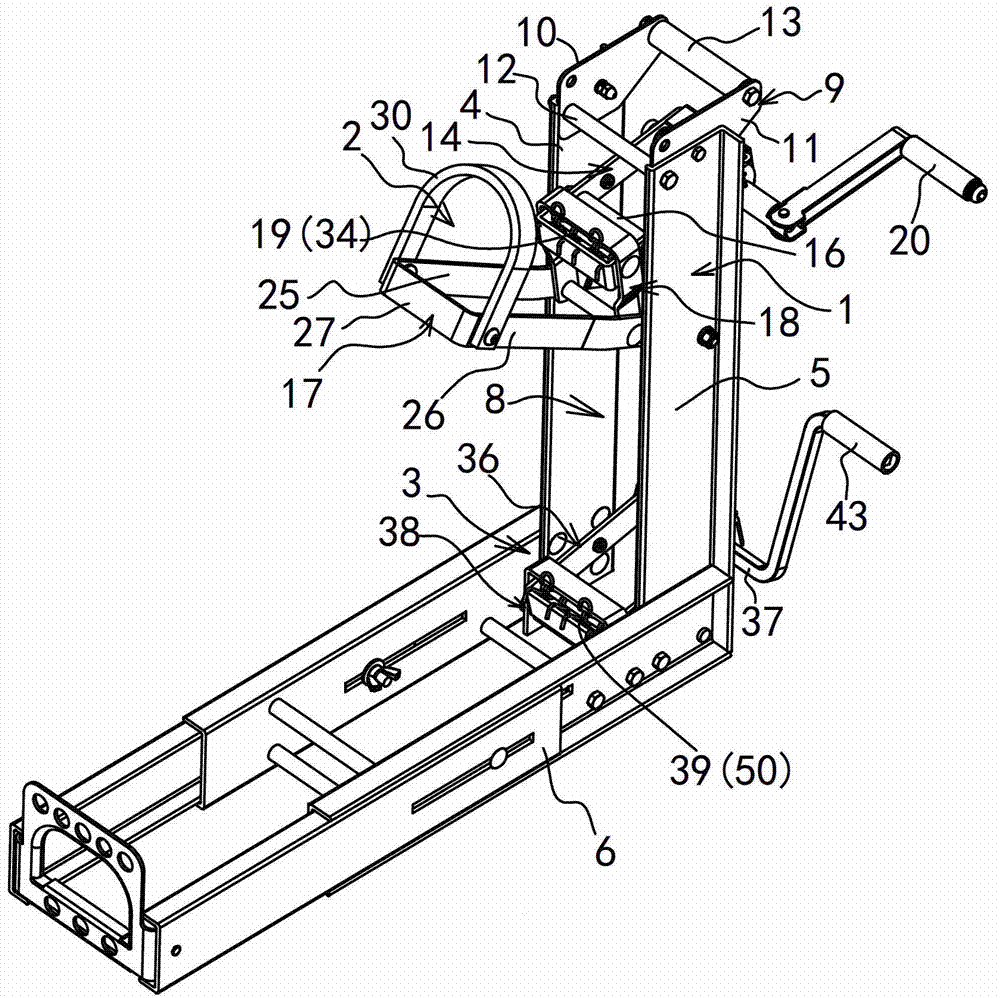

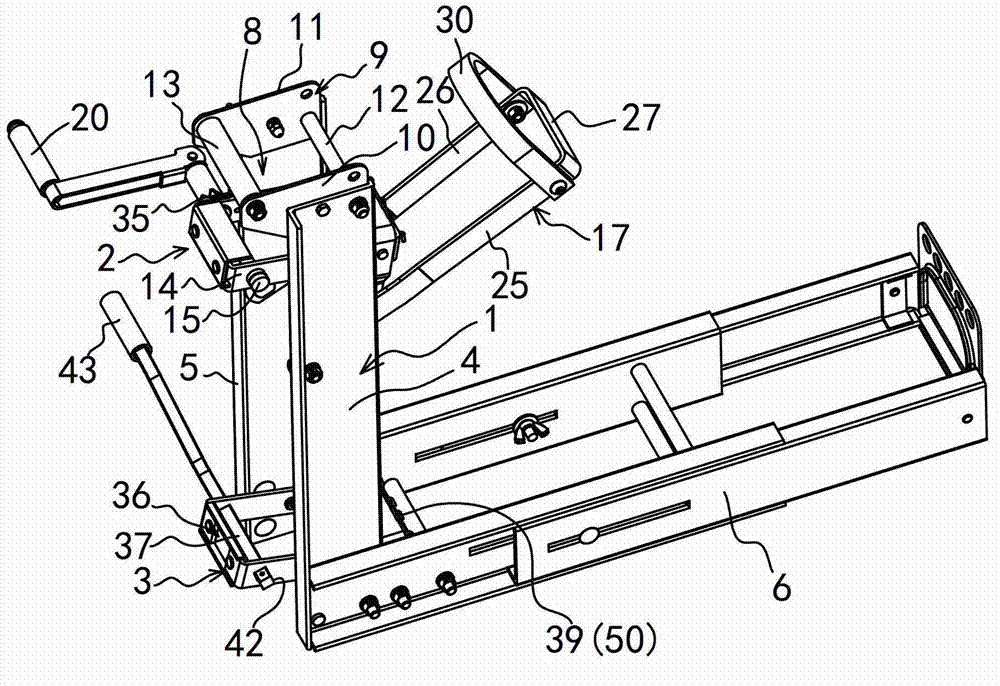

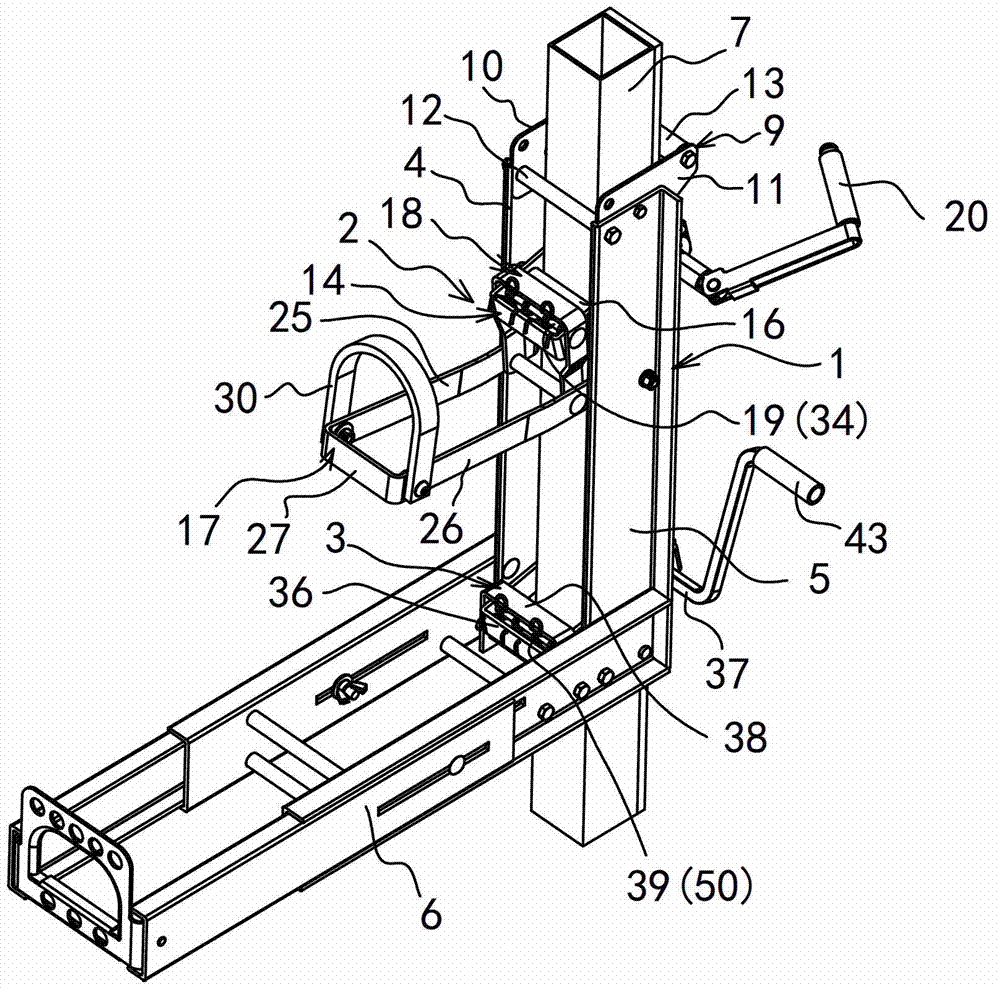

[0033] Example: see attached figure 1 ~ attached Figure 10 Shown:

[0034] A lifting bracket is composed of a fixed sleeve frame 1, a foot pump driving mechanism 2 and a drop limiting mechanism 3.

[0035] The fixed sleeve frame 1 includes a left side plate 4 , a right side plate 5 , a bracket 6 for placing pedals and a top guide frame 9 . The left side plate 4 and the right side plate 5 are left and right opposite, and between the left side plate 4 and the right side plate 5, a longitudinal space 8 for accommodating the column 7 is formed. The lower end is fixed forward. Top guide frame 9 is made up of left connector 10, right connector 11, front guide wheel 12 and rear guide wheel 13. The left connecting piece 10 and the right connecting rod 11 are arranged opposite to each other. The front guide wheel 12 is connected between the front ends of the left connecting piece 10 and the right connecting rod 11, and the rear guide wheel 13 is connected behind the left connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com