A high-altitude manual pull wire making pliers

A handle and space technology, applied in the field of high-altitude manual wire-pulling pliers, can solve problems such as affecting work efficiency and inconvenience, and achieve the effects of improving work efficiency, being convenient to carry, and avoiding climbing up and down.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

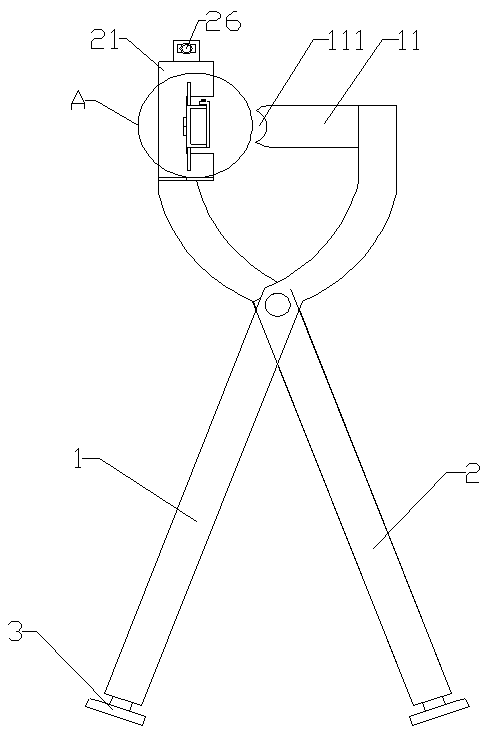

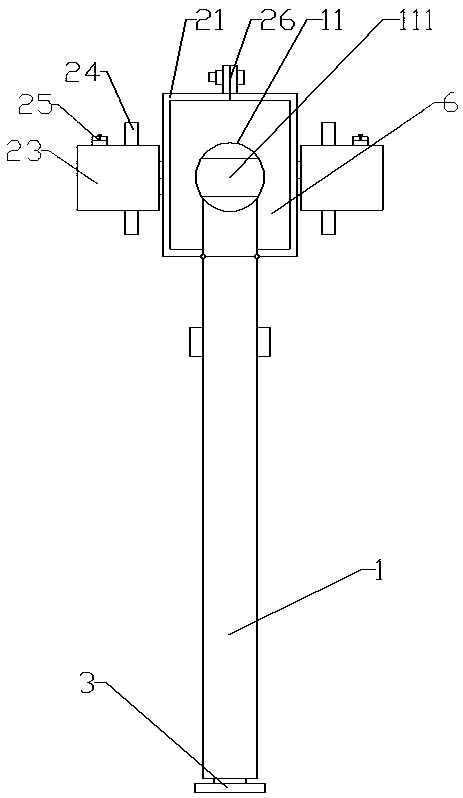

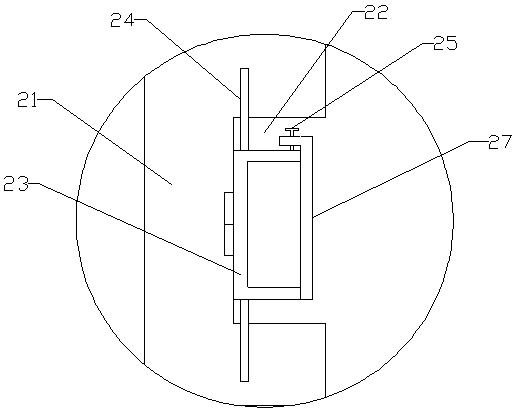

[0017] Accompanying drawing is the specific embodiment of the present invention. Such as Figure 1 to Figure 4 As shown, this kind of high-altitude manual pull wire making pliers includes two handles: left handle 1 and right handle 2. Two splints 21 are paired together to form a space 6, the bisector of the space 6 in the up and down direction coincides with the plane where the left handle 1 and the right handle 2 are located, and the upper ends of the two splints 21 are connected by a bolt fastener 26 Together, the nuts in the bolt fasteners 26 use butterfly nuts, which are convenient for manual operation. Two splints 21 open a gap 22 towards one end of the left handle 1, and the top of the right handle 2 is hinged with two opposing Plywood 21, a space 6 is formed between two splints 21, a notch 22 is respectively opened at one end of the splint 21 close to the left handle 1, the notch 22 faces the left handle 1, and the bottom of each notch 22 is hinged with a cable groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com