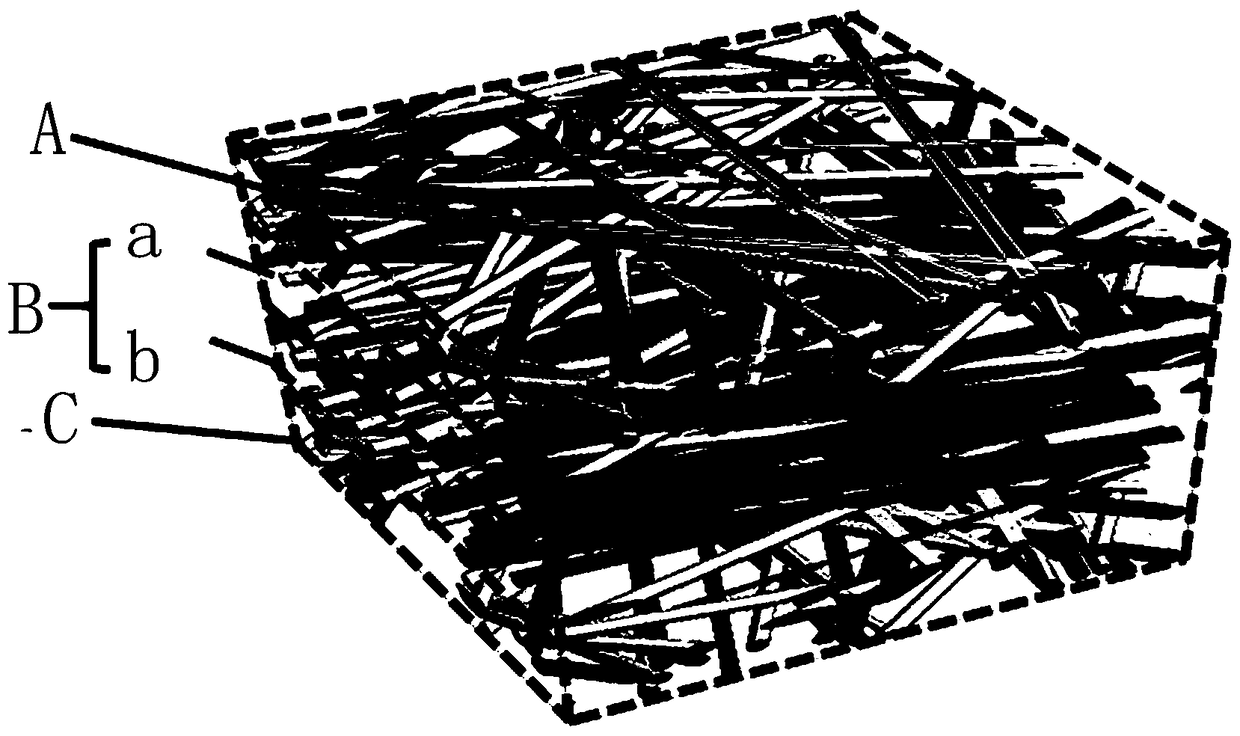

Multi-layer fiber web and preparation method thereof

A fiber web and multi-level technology, which is applied in the field of nonwoven material preparation technology, can solve the problems of carded fiber web with single structure, insufficient functionality, and high equipment cost, so as to improve moisture conductivity, reduce the difference in vertical and horizontal diffusion speeds, and reduce costs. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

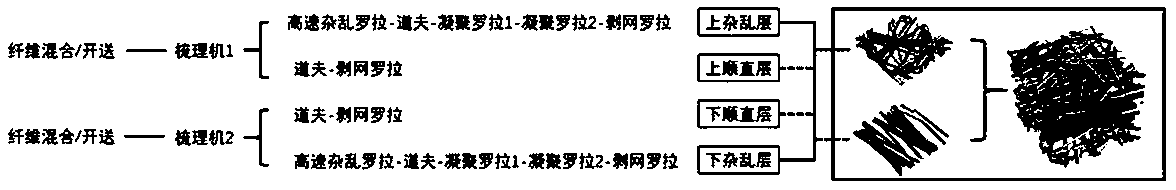

[0042] A method for preparing a multi-level fiber web, the steps are as follows:

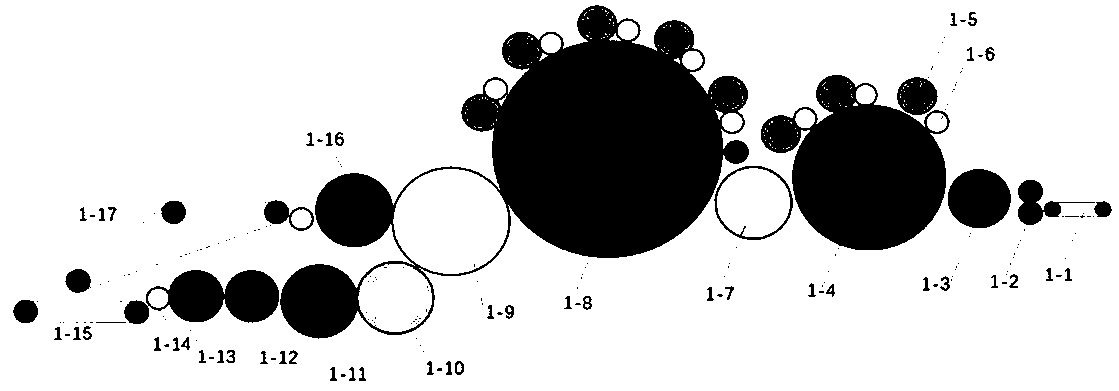

[0043] Among them, the main cylinder machine includes main cylinder Ⅰ and main cylinder Ⅱ, both of which have the same structure; the full transfer roller includes full transfer roller Ⅰ and full transfer roller Ⅱ, both of which have the same structure; the high-speed random roller includes high-speed random roller Ⅰ and High-speed messy roller II, both of which have the same structure; agglomeration roller 1 includes agglomeration roller I-1 and agglomeration roller II-1, both of which have the same structure; agglomeration roller 2 includes agglomeration roller I-2 and agglomeration roller II-2, both of which have the same structure same.

[0044] Viscose fiber (1.67dtex, 38mm) and PET (3D, 38mm) are selected as raw materials; the process adopts opening-carding-mixing and then needling to fix the net, and the specific steps refer to the experimental method, in which the feeding machine is a po...

Embodiment 2

[0046] A method for preparing a multi-level fiber web, the steps are as follows:

[0047] Among them, the main cylinder machine includes main cylinder Ⅰ and main cylinder Ⅱ, both of which have the same structure; the full transfer roller includes full transfer roller Ⅰ and full transfer roller Ⅱ, both of which have the same structure; the high-speed random roller includes high-speed random roller Ⅰ and High-speed messy roller II, both of which have the same structure; agglomeration roller 1 includes agglomeration roller I-1 and agglomeration roller II-1, both of which have the same structure; agglomeration roller 2 includes agglomeration roller I-2 and agglomeration roller II-2, both of which have the same structure same.

[0048] Viscose fiber (1.67dtex, 38mm) and PET (3D, 38mm) are selected as raw materials; the process adopts opening-carding-mixing and then needling to fix the net, and the specific steps refer to the experimental method, in which the feeding machine is a po...

Embodiment 3

[0050] A method for preparing a multi-level fiber web, the steps are as follows:

[0051] Among them, the main cylinder machine includes main cylinder Ⅰ and main cylinder Ⅱ, both of which have the same structure; the full transfer roller includes full transfer roller Ⅰ and full transfer roller Ⅱ, both of which have the same structure; the high-speed random roller includes high-speed random roller Ⅰ and High-speed messy roller II, both of which have the same structure; agglomeration roller 1 includes agglomeration roller I-1 and agglomeration roller II-1, both of which have the same structure; agglomeration roller 2 includes agglomeration roller I-2 and agglomeration roller II-2, both of which have the same structure same.

[0052] Viscose fiber (1.67dtex, 38mm) and PET (3D, 38mm) are selected as raw materials; the process adopts opening-carding-mixing and then needling to fix the net, and the specific steps refer to the experimental method, in which the feeding machine is a po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com