Wood structure fabricated type profile steel bolt joint

A bolt joint and assembly technology, which is applied in the direction of building construction and construction, can solve problems such as difficult installation, achieve the effects of facilitating construction and installation, avoiding premature cracking damage, and increasing the cracking load of transverse grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

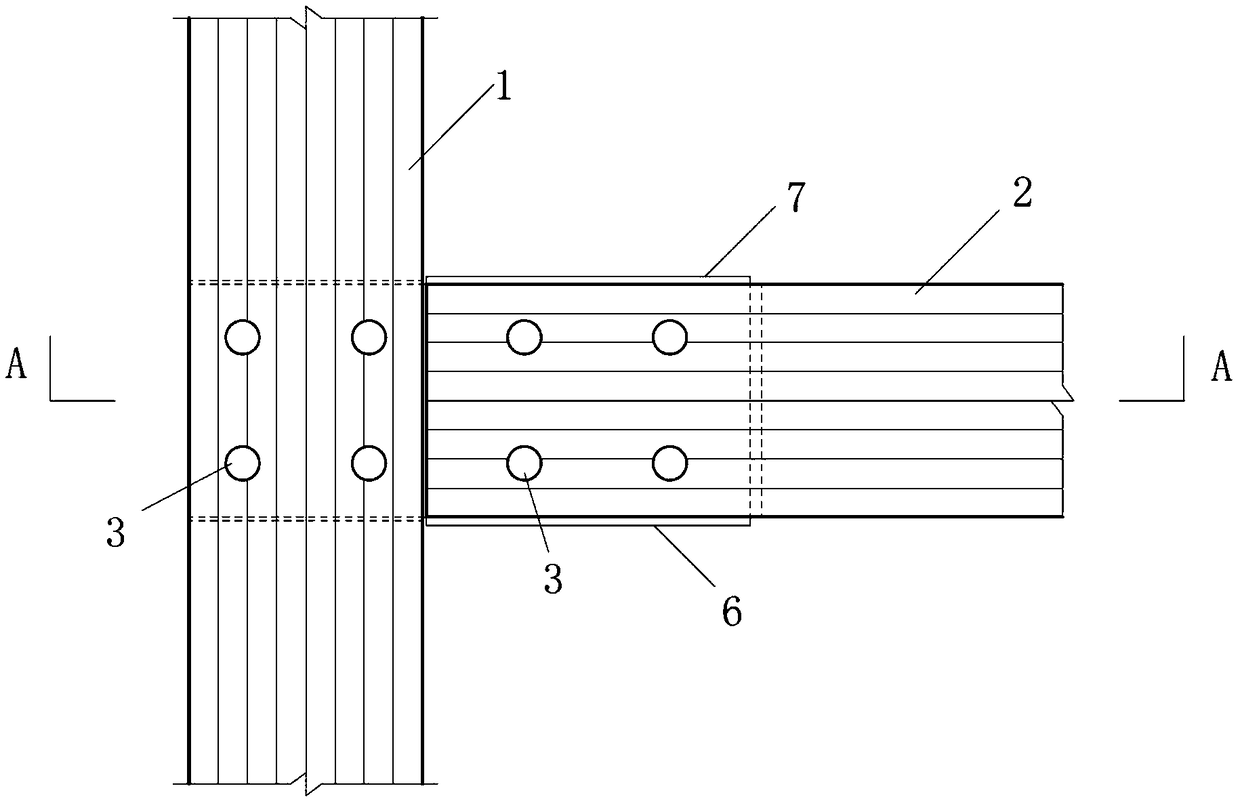

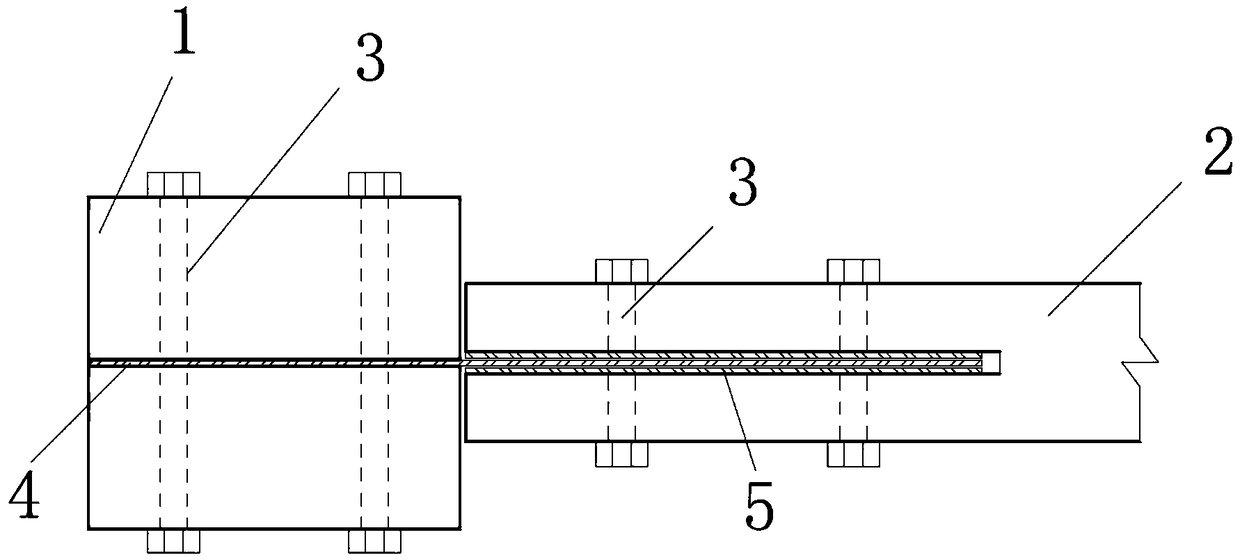

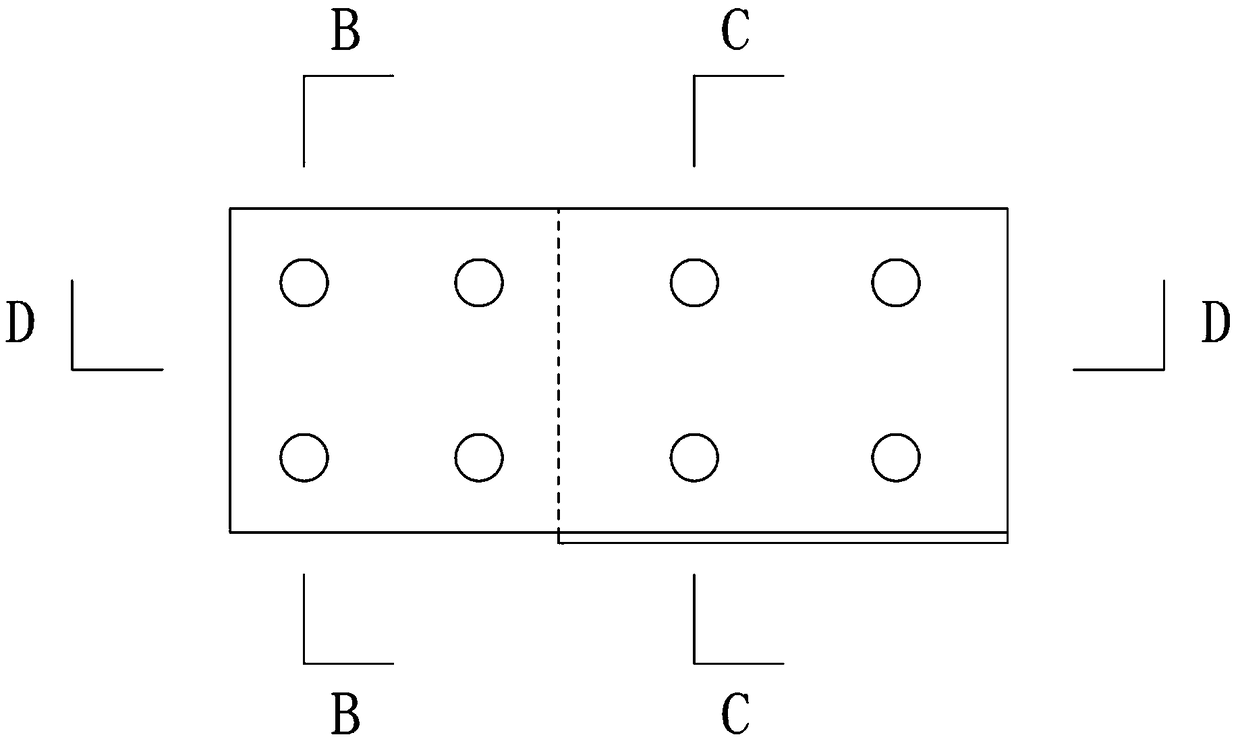

[0045] Assembled steel bolt joints of wood structure, the structure is like Figure 1 to Figure 11 As shown, it includes a first wooden member 1 and a second wooden member 2 connected to each other, and a first inner-filled steel plate 4, which is embedded in the second wooden member 2 and passes through the first wooden member 1. Used to connect two wooden components;

[0046] In addition, the wood structure fabricated steel bolt joints also include:

[0047] The first side steel plate 6 is wrapped on the lower surface of the wood in the node area of the second wooden member 2 and cooperates with the second side steel plate 7 to improve the tensile capacity of the second wooden member in the transverse direction.

[0048] The wood structure fabricated steel bolt joint also includes a second inner-filled steel plate 5, which is wrapped around the first inner-filled steel plate 4, and is embedded in the second wooden member 2 together with the first inner-filled steel plate 4.

[004...

Embodiment 2

[0052] A wood structure bolted steel plate node, its structure is like Figure 12 to Figure 22 As shown, it includes a first wooden member 1 and a second wooden member 2 connected to each other, and a first inner-filled steel plate 4, which is embedded in the second wooden member 2 and passes through the first wooden member 1. Used to connect two wooden components;

[0053] In addition, the wood structure fabricated steel bolt joints also include:

[0054] The first side steel plate 6 is wrapped on the lower surface of the wood in the node area of the second wooden member 2 and cooperates with the second side steel plate 7 to improve the tensile capacity of the second wooden member in the transverse direction.

[0055] The wood structure fabricated steel bolt joint also includes a second inner-filled steel plate 5, which is embedded in the second wooden member 2 together with the first inner-filled steel plate 4.

[0056] The wood structure prefabricated steel bolt joints also incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com