Traction machine for electric power dispatching power grid construction

A technology of electric power dispatching and stretching machine, which is applied in the direction of mechanical equipment, transmission device parts, and conveying filamentous materials, etc. It can solve the problems of increased centrifugal force of the conveying wheel, increased rotational speed, and fast rotational speed of the conveying wheel, so as to prevent excessive speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

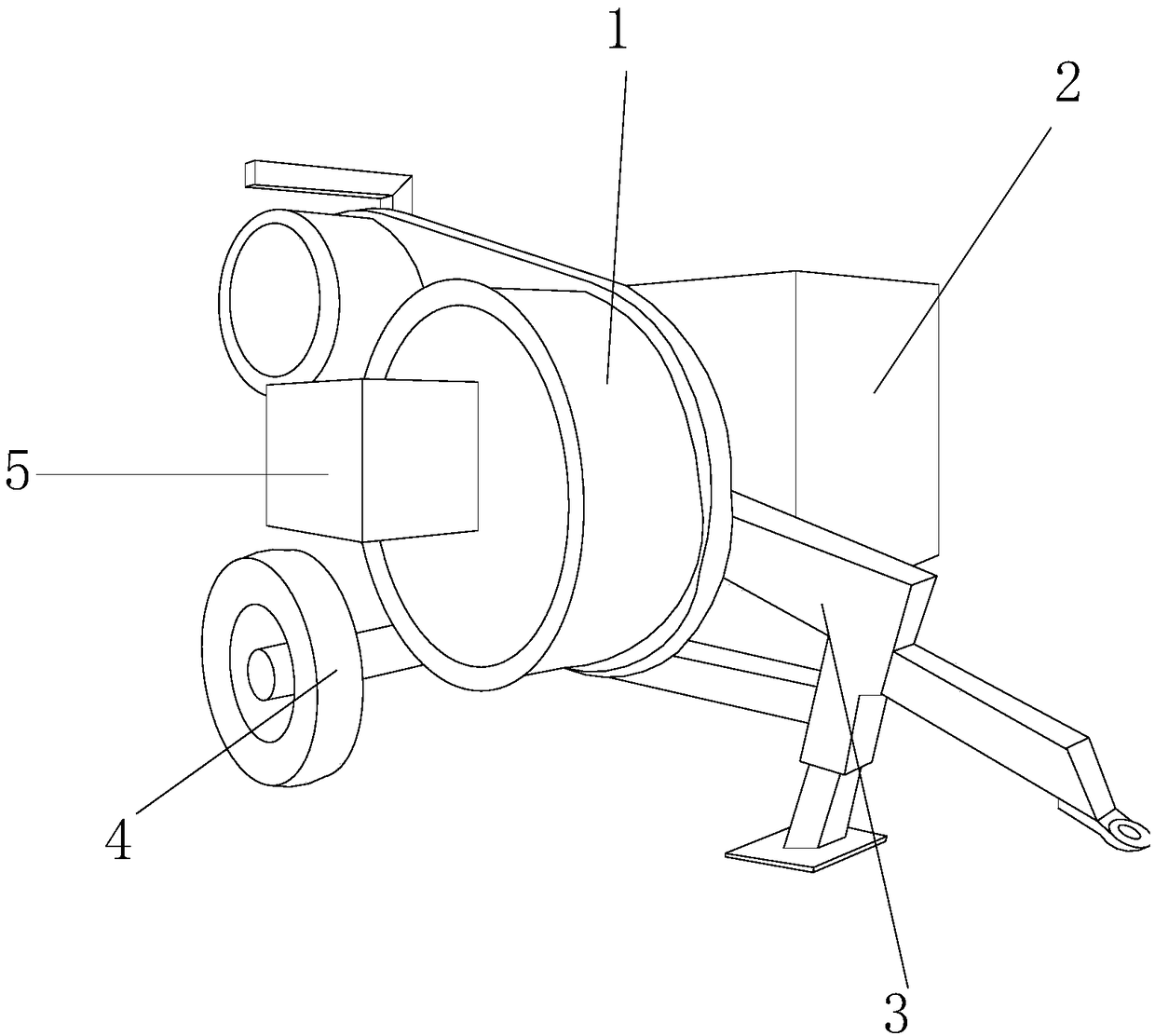

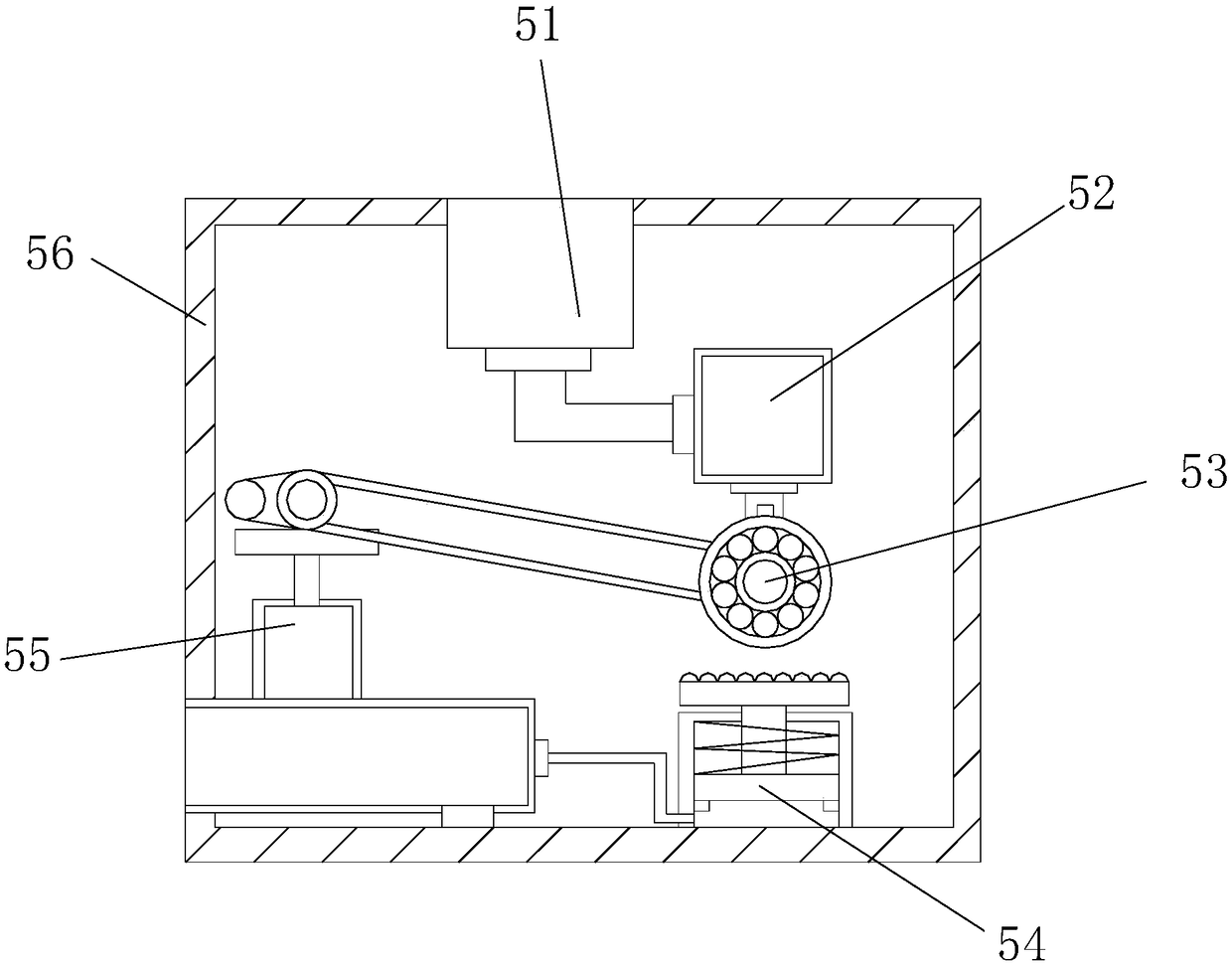

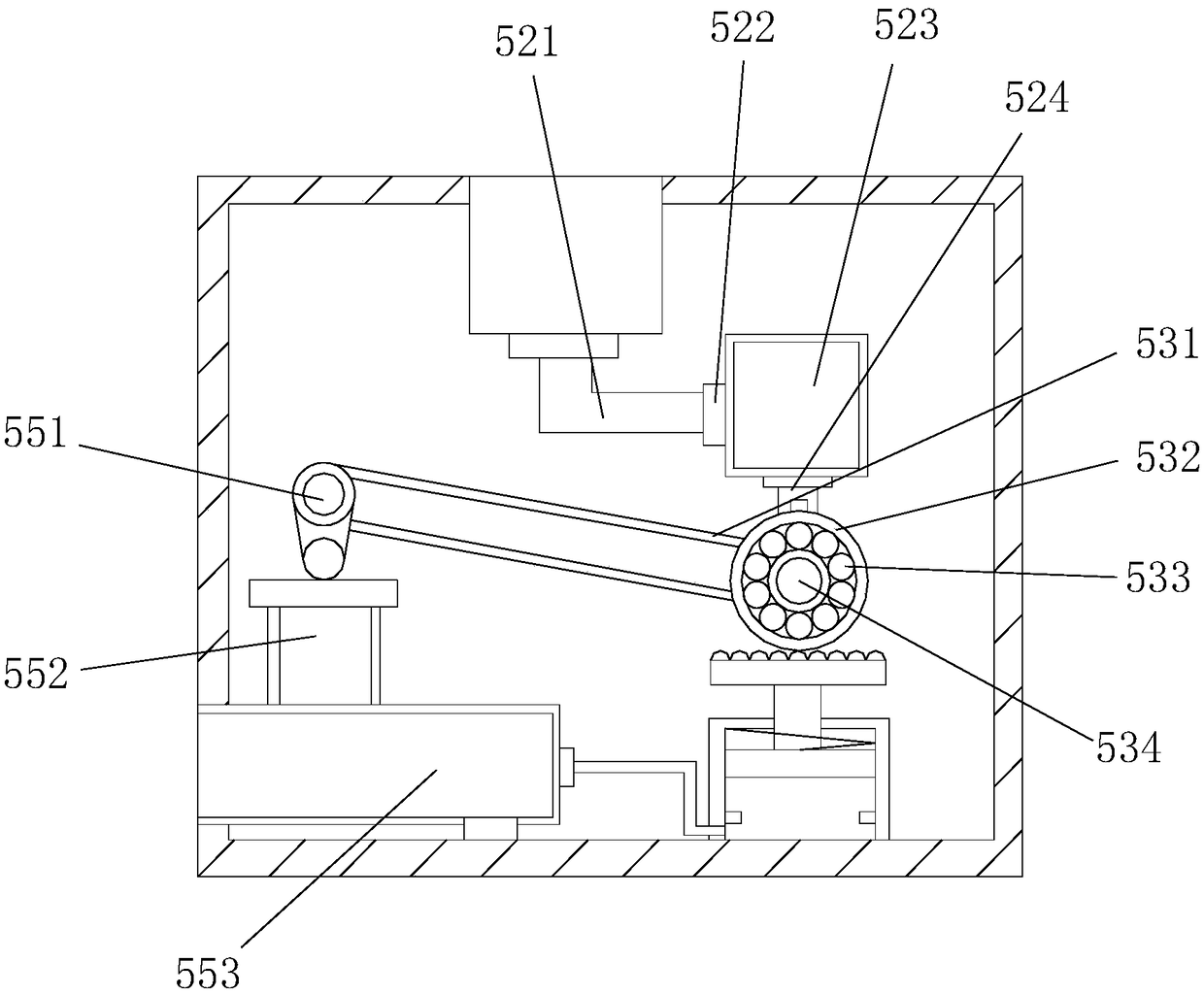

[0026] see Figure 1-Figure 7, the present invention provides a stretcher for power dispatching power grid construction, its structure includes a conveying wheel 1, a control box 2, a support frame 3, a roller 4, and an axle box 5, and the conveying wheel 1 is arranged at the front end of the control box 2, and two The bottom end of the control box 2 is welded to the top of the support frame 3, the roller 4 is located under the axle box 5, the rear end of the axle box 5 is located at the front end of the conveying wheel 1, and the two The axle box 5 includes a filling mechanism 51, a lubrication dripping mechanism 52, a rotating connection shaft assembly 53, a speed reduction mechanism 54, a speed detection mechanism 55, and a housing 56. The top of the filling mechanism 51 and the top of the housing 56 Welded together, the lubricating dripping mechanism 52 is located directly above the rotating connection shaft assembly 53, and the two are movably connected, the reduction mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com