Top-drawing type pay-off rack

A pay-off frame and frame technology, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of messy wires and slow wire speed, and achieve fast wire defense, fast wire defense, and adjustment Convenient and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

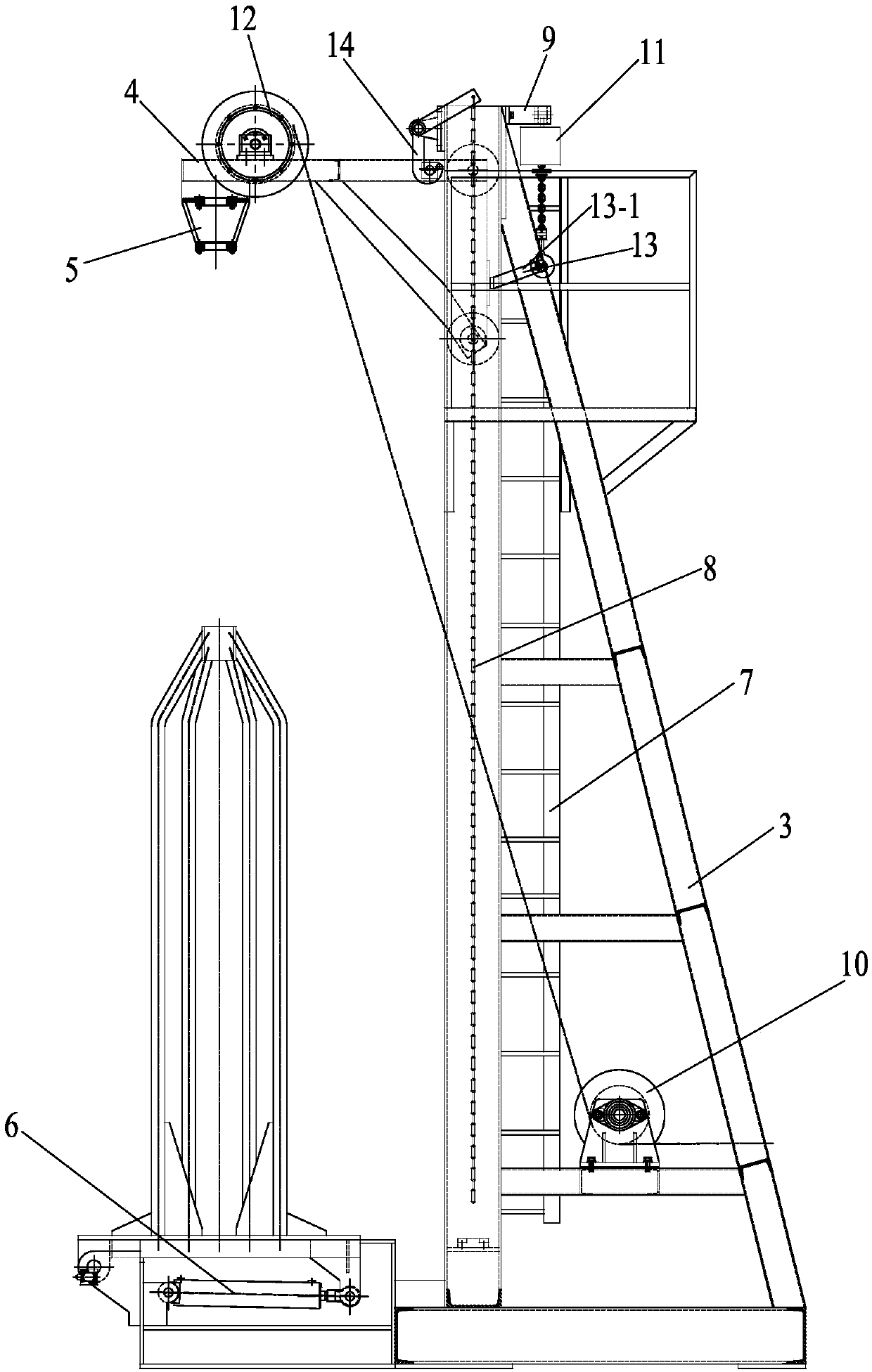

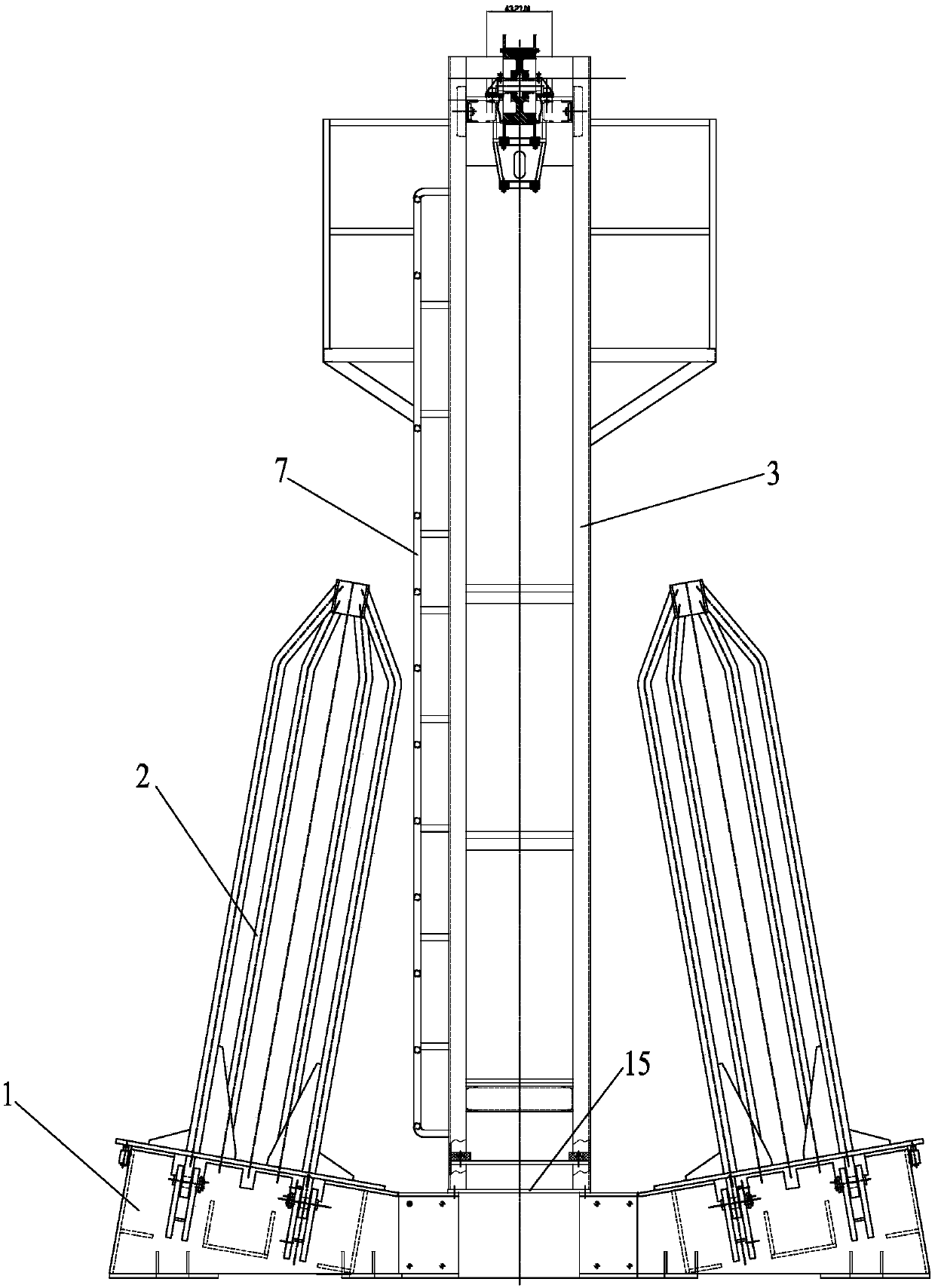

[0014] figure 1 , 2 Among them, including base 1, wire barrel 2, frame 3, lifting frame 4, frame basket 5, hydraulic cylinder 6, ladder 7, iron chain 8, fixed seat 9, guide wheel 2 10, electric hoist 11, guide wheel 1 12 , connecting seat 13, support arm 13-1, hook frame 14, connecting plate 15, etc.

[0015] Such as figure 1 , 2 As shown, the present invention is a kind of upward drawing type pay-off stand, comprises base 1, and frame 3 is installed on the middle platform of base 1, and a wire barrel 2 is respectively hinged on the installation station on both sides of base 1, when in use, wire The cylinder 2 is driven by the hydraulic cylinder 6 installed on the base 1 to rotate around the hinge point; the ladder 7 is installed on the frame 3, the lifting frame 4 is connected to the upper part of the frame 3 in rotation, and an electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com