Magnetic ring casting, magnetic ring casting mold and magnetic ring casting device manufacturing method

A manufacturing method and magnetic ring technology, which are applied in the manufacture of inductors/transformers/magnets, magnets, magnetic objects, etc., can solve the problems of easy bump damage at the edges and corners of the magnetic ring, and achieve the effect of avoiding bump damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

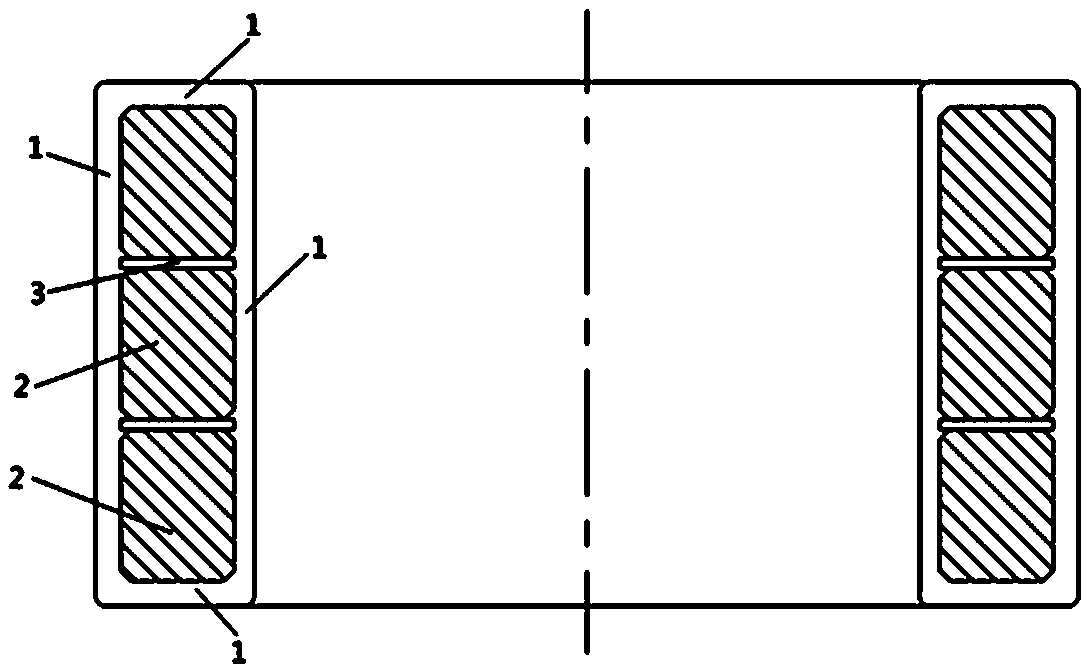

[0024] Examples of magnetic ring casting are figure 1 As shown: It includes a magnetic ring body composed of three magnetic rings 2 arranged in sequence along the up and down direction. The magnetic rings are made of ferrite materials. Two adjacent magnetic rings are separated by insulating gaskets 3. The insulating gasket The sheet 3 is adhesively connected to the two adjacent magnetic rings. The inner wall, outer wall, bottom and top of the magnetic ring body are poured with a casting body 1 with an integral structure with the magnetic ring body, wherein the casting body cast at the bottom of the magnetic ring body is provided with a positioning support column ( figure 1 not shown), the lower end of the positioning support column is flush with the lower end of the pouring body 1 . For the manufacturing process of the magnetic ring casting, please refer to the following magnetic ring casting mold and the manufacturing method of the magnetic ring casting.

[0025] In other e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com