Branch bundling machine for Christmas tree branches

A branch binding machine and branch technology, applied to floor fabrics, applications, household appliances, etc., can solve the problems of increasing production costs, increasing the rate of defective products, and inconvenient operation of manipulators, so as to improve space utilization and reduce binding. Branch error rate, improve the effect of space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

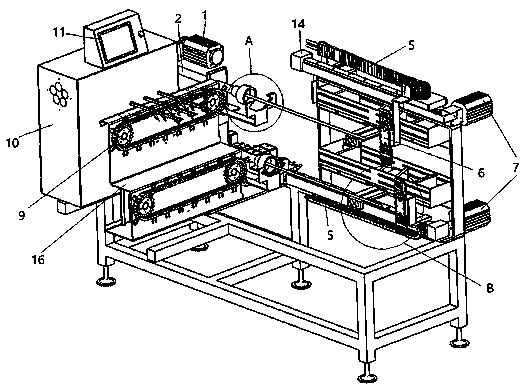

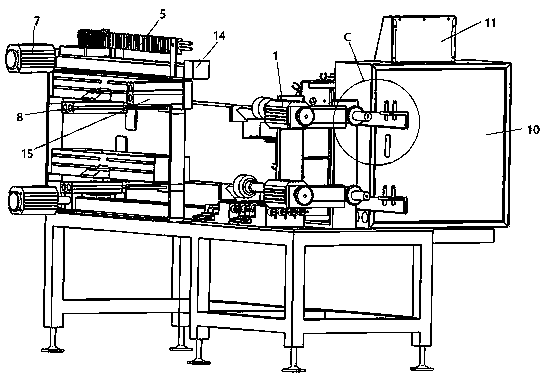

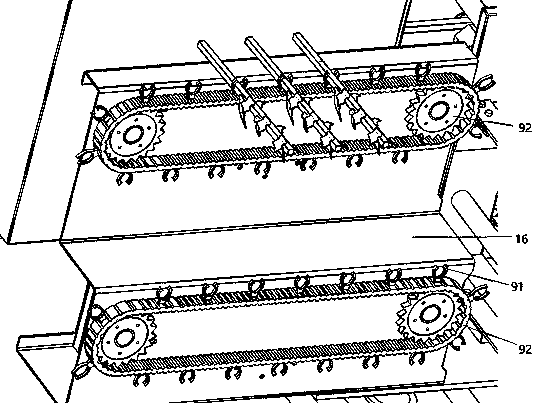

[0026] combine figure 1 , figure 2 , Figure 4 , Figure 6 and Figure 7 It can be seen that a tying machine for Christmas tree branches includes a moving mechanism, a winding mechanism and a feeding mechanism, the moving mechanism is on one side of the winding mechanism and parallel to it, and the feeding mechanism is perpendicular to the winding mechanism and on the other side; The winding mechanism includes a first cylinder 1, a wire tube 2 and an inner concave part 3, the first cylinder 1 and one end of the wire tube 2 are connected by a rotating belt, and the other end of the wire tube 2 is connected and fixed with the inner concave part 3; There are wire entry hole 21 and pipe hole 22, pipe hole 22 runs through the tube core of wire pipe 2, wire entry hole 21 is set beside pipe hole 22 and runs through wire pipe 2; wire entry hole 21 is divided into dark hole 12 and open slot 13 , the dark hole 12 is the end close to the wire inlet 21 and the first cylinder 1, the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com