A feeding and clamping mechanism

A clamping mechanism and material feeding technology, which is applied in the field of mechanical devices, can solve the problems of large cumulative product error, low feeding quality and efficiency, and poor control of material tightness, so as to improve efficiency, avoid damage, and position precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038]The following is a specific embodiment of the present invention and a further description of the technical solutions of the present invention, but the present invention is not limited to these embodiments.

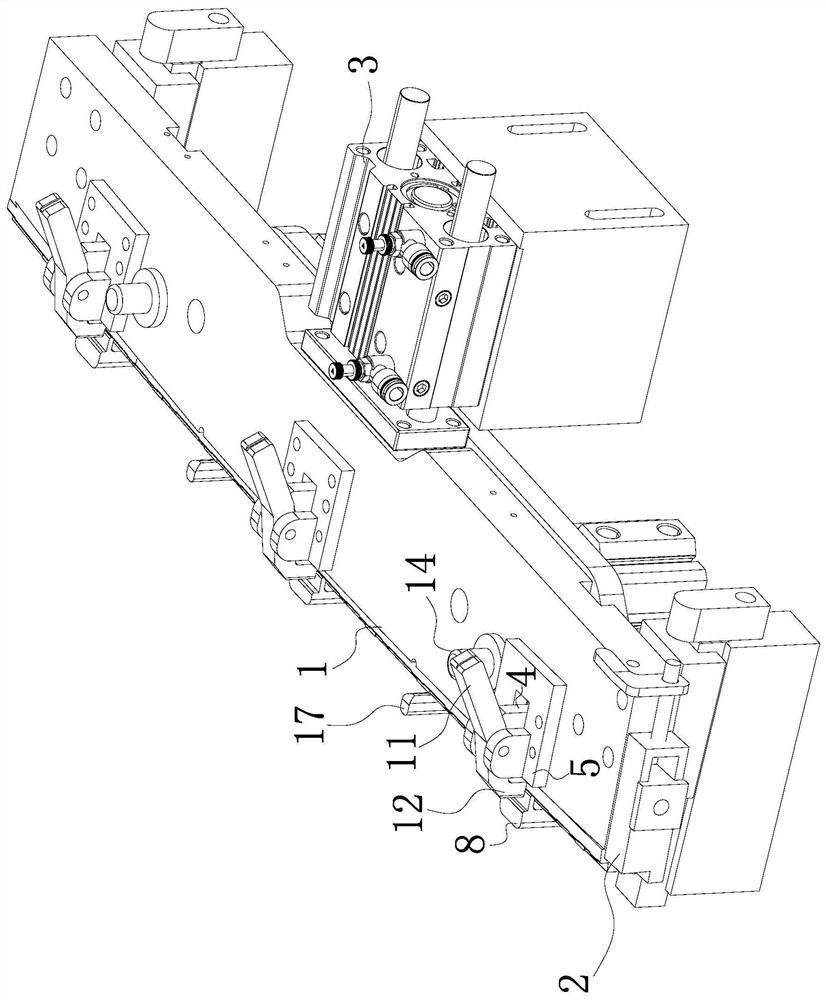

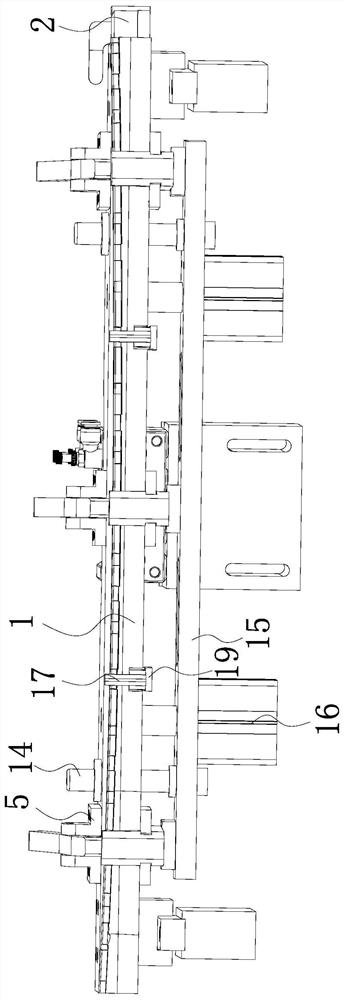

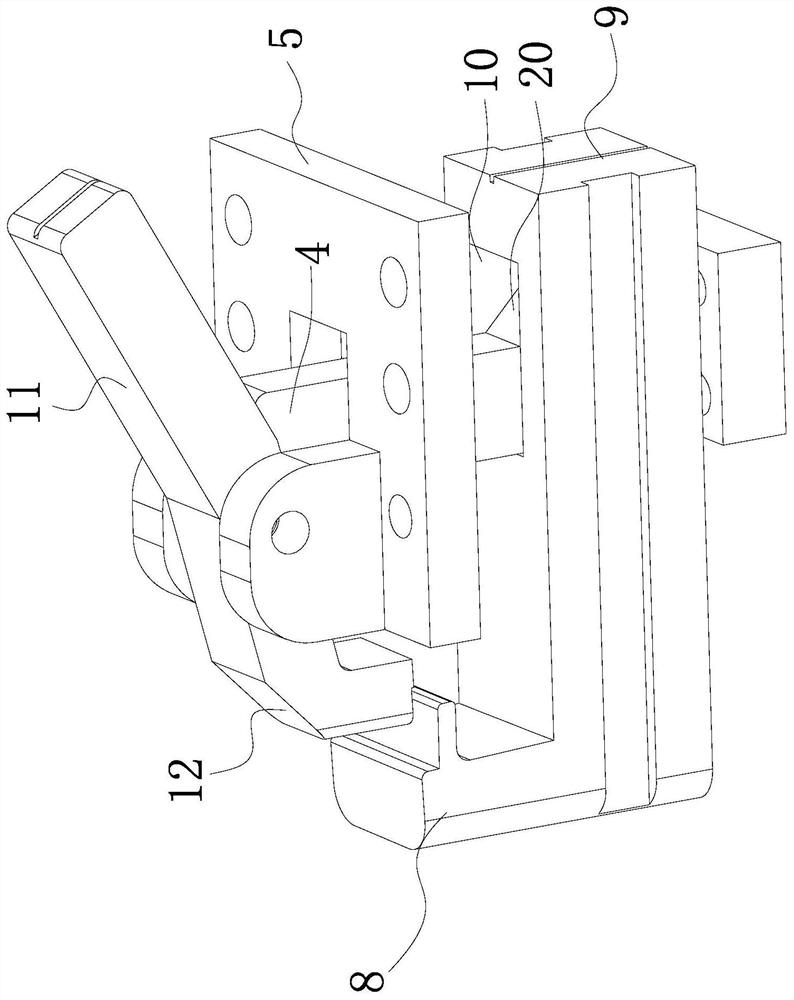

[0039]Such asFigure 1 to 6As shown, the feed clamping mechanism includes: a workpiece plate 1; end positioning assembly 2, which is disposed at the end of the workpiece plate 1; pre-clamping assembly, the activity is disposed on the workpiece plate 1; Lifting assembly, its activity is connected to the lower end of the workpiece plate 1; the workpiece fixing assembly is inserted on the workpiece plate 1 and its lower end is connected to the lifting assembly; when the lifting assembly rises, the workpiece fixing component can abut The side end and the upper end of the workpiece; push the cylinder 3, which is disposed on the side end of the workpiece plate 1, and the pushing the cylinder can be moved before and after moving the workpiece plate 1.

[0040]The workpiece placed plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com