Fabricated type wood structure beam column connecting joint

A beam-column connection and wood structure technology, which is applied in building structure, construction and other directions, can solve the problems of long construction period, weak connection, difficult construction, etc., and achieve the effect of short construction period, solving construction difficulties and convenient construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

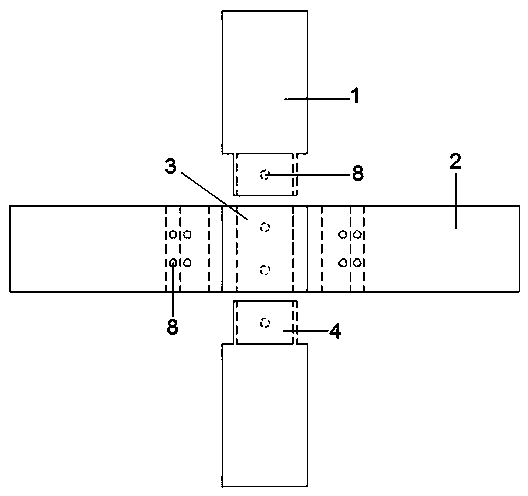

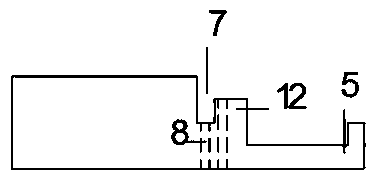

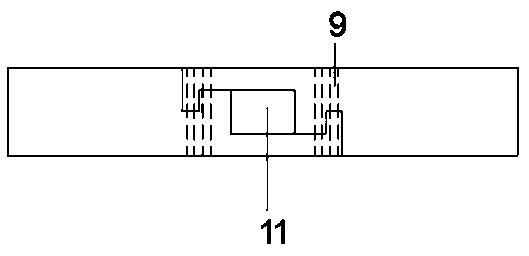

[0023] Example 1: Such as figure 1 -As shown in 8, a prefabricated wooden structure beam-column connection node, including wooden cylinder 1, wooden beam 2, steel plate 3, rectangular rib 4, L-shaped rib 5, rectangular groove 6, L-shaped groove 7, reserved Reinforced steel hole 8, threaded steel bar 9, nut 10, gap between beams 11, rectangular protrusion 12 on the beam, rectangular groove 13 between the ribs, the wooden cylinder 1 is symmetrically arranged on the upper and lower sides of the wooden beam 2 In the middle position, rectangular ribs 4, rectangular grooves 6, pre-reinforced holes 8, and rectangular grooves between ribs 13 are arranged in wooden cylinder 1, and rectangular ribs 4, rectangular grooves 6, and rectangular grooves between ribs at the bottom of wooden cylinder 1 13 are arranged alternately. The part of the wooden column 1 whose cross section is larger than that of the wooden beam 2 is solid and the wooden beam 2 is wrapped in the wooden column 1. The solid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com