Novel connecting structure of lens and shell of automobile head lamp

A technology of connecting structure and light distribution mirror, applied in the direction of headlights, vehicle parts, light source fixing, etc., can solve the problems of poor welding performance and increase the welding defect rate, and achieve the effect of fast connection speed, high yield rate and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

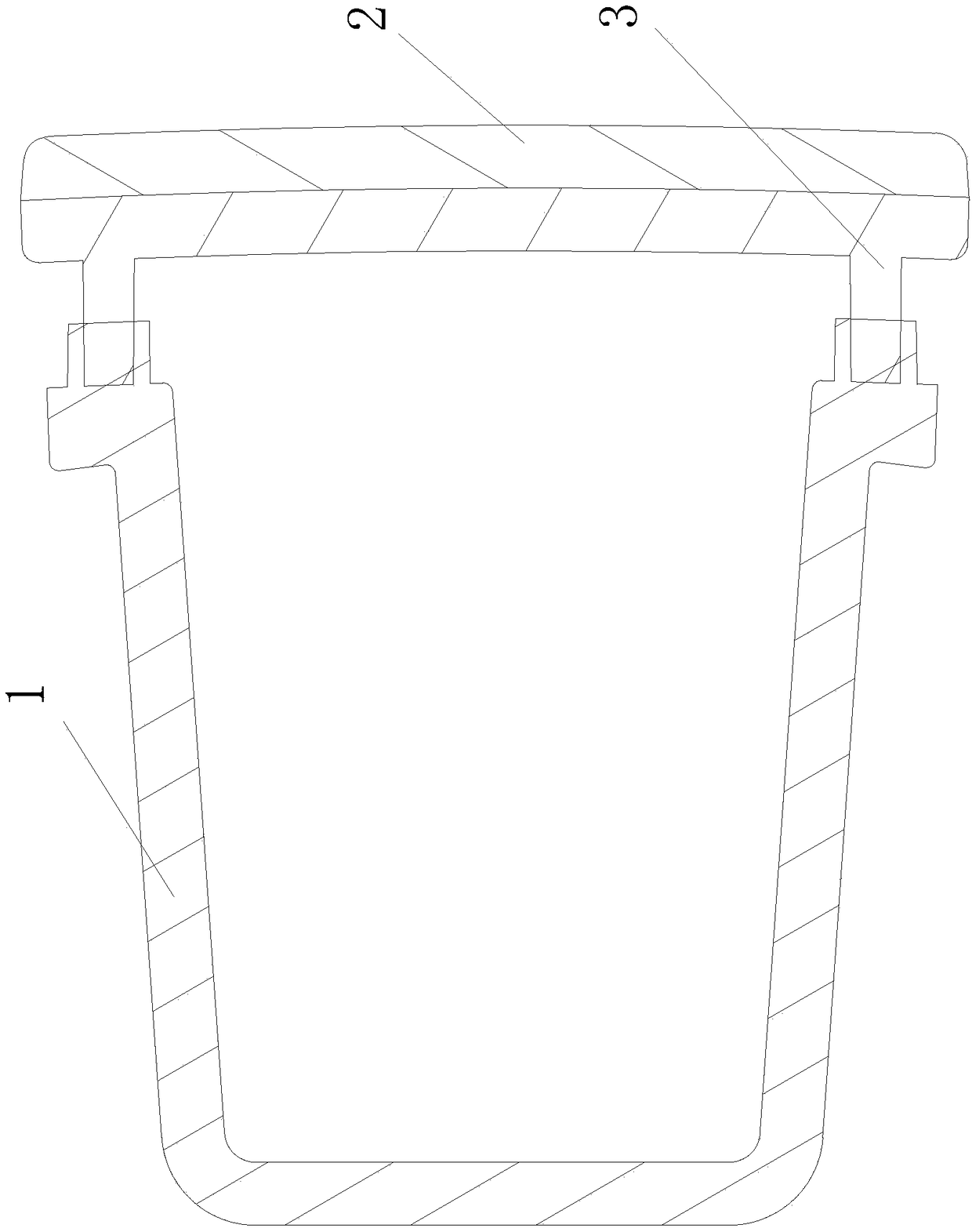

[0019] Such as figure 1 As shown, the present invention includes a casing 1 , a PC light distribution mirror 2 , and an intermediate layer 3 . The middle layer 3 is made of PMMA, and the whole surface of the middle layer 3 close to the PC light distribution mirror 2 and the PC light distribution mirror 2 are in a hot-melt state to penetrate and combine with each other to form a whole, and they are bonded and fixed together. The housing 1 There is a ring groove on the top, and the side of the middle layer 3 close to the shell 1 is provided with ribs protruding into the ring groove. The ring groove and the rib are welded together so that the side of the middle layer 3 close to the shell 1 and the shell Body 1 is welded together.

Embodiment 2

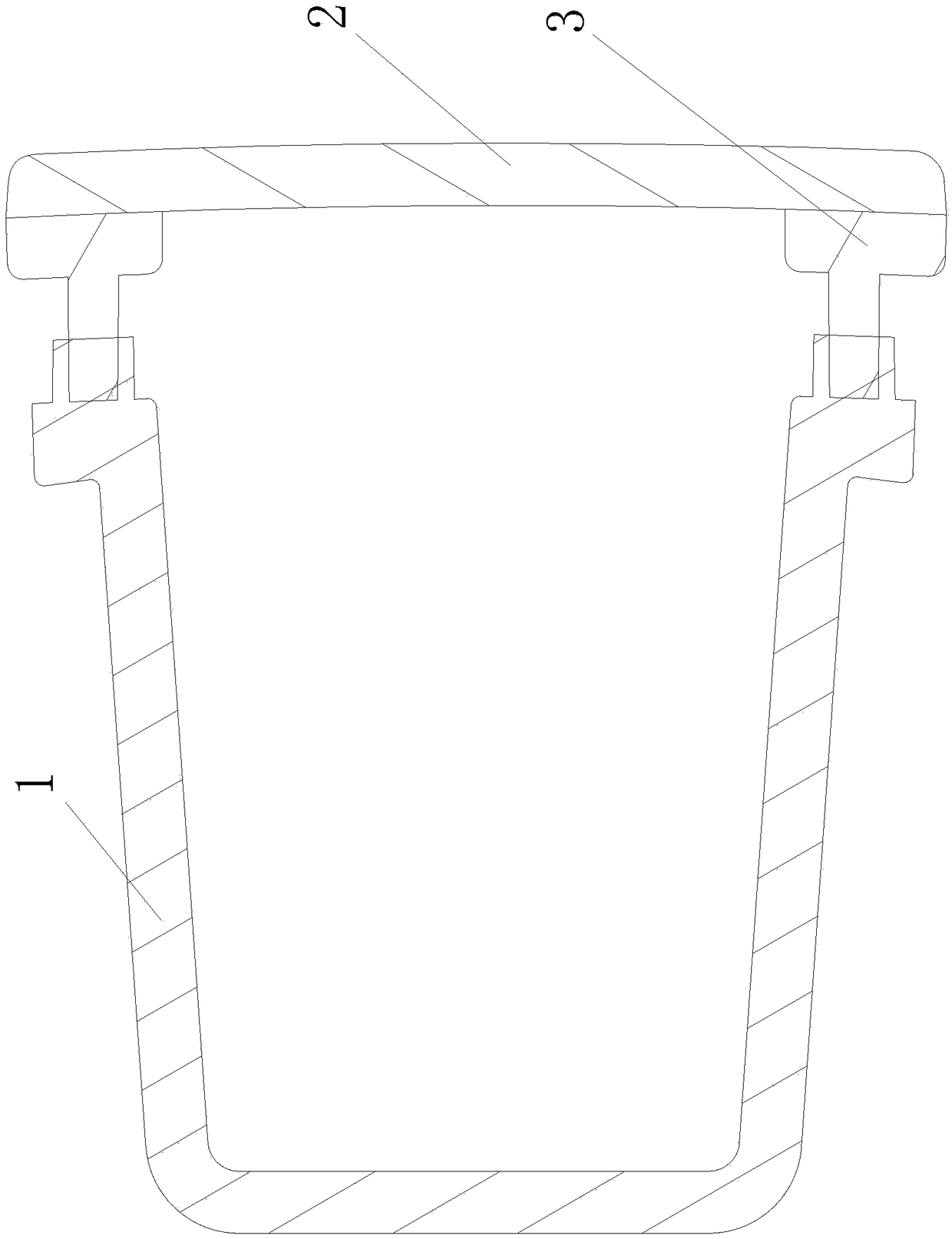

[0021] Such as figure 2 As shown, the difference between the present embodiment and the first embodiment is that in the present embodiment, the surface where the intermediate layer 3 and the PC lens 2 are attached and fixed together is ring-shaped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com