Special capacitive grounding device for maneuvering field operations

A grounding device and mobile technology, applied in the direction of connecting contact materials, etc., can solve the problems of poor operability on the battlefield, bending and deforming steel brazing, breaking steel brazing, etc., so as to improve mobility, combat radius, and good safety guarantee , to reduce the effect of higher grounding resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

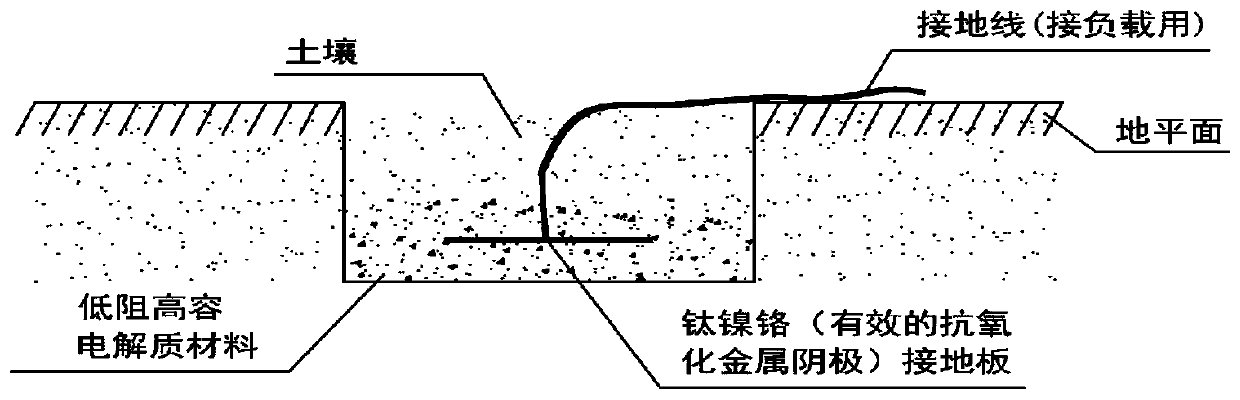

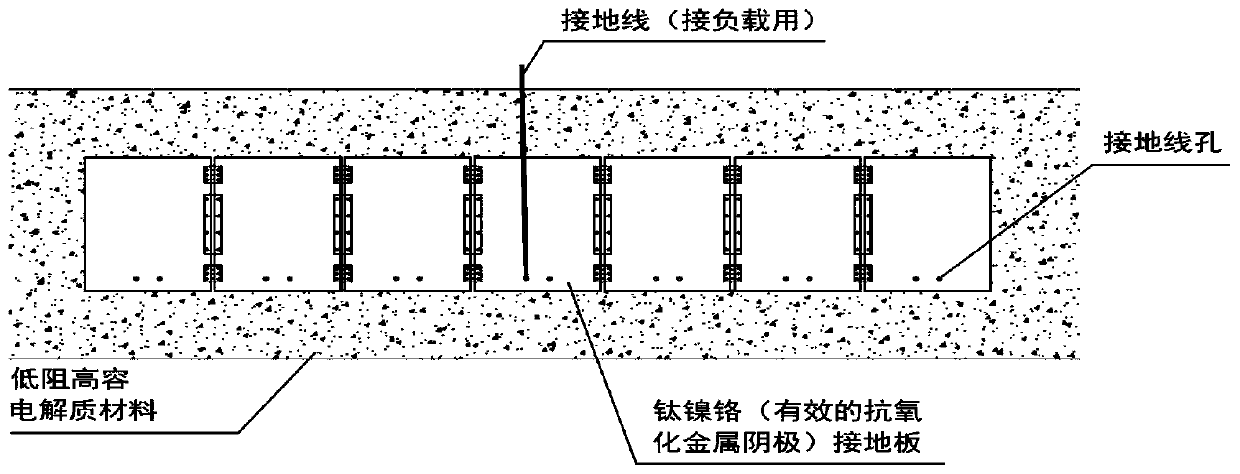

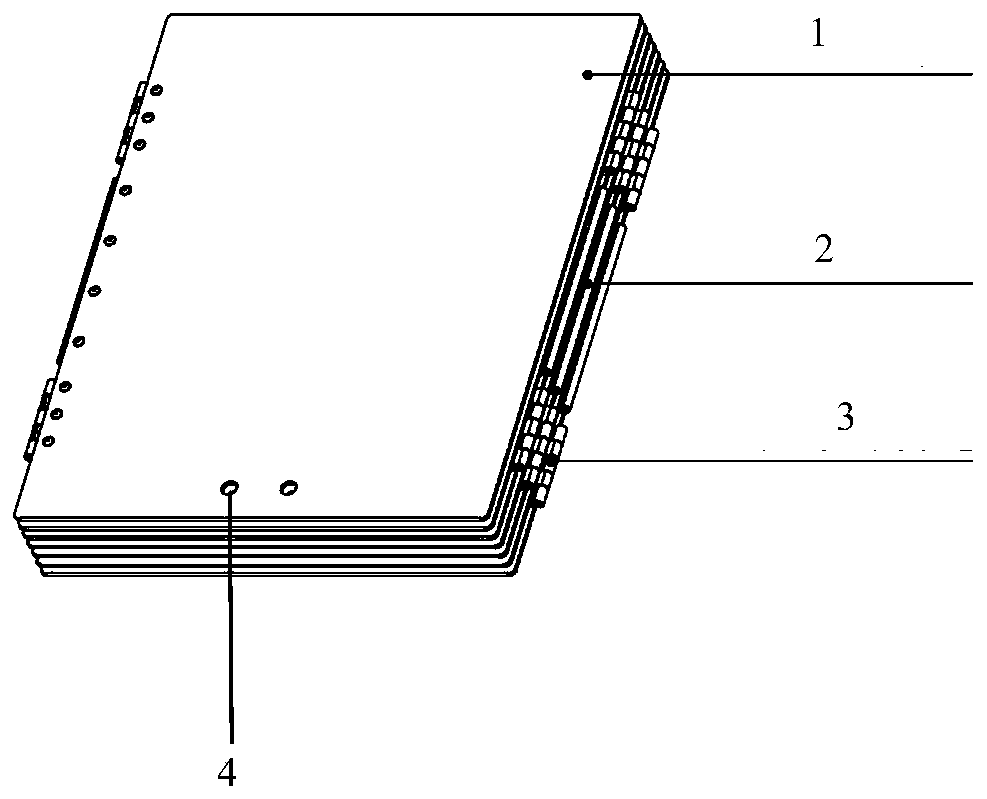

[0032] In order to facilitate the understanding of the embodiments of the present invention, several specific embodiments will be taken as examples for further explanation below in conjunction with the accompanying drawings, and each embodiment does not constitute a limitation to the embodiments of the present invention.

[0033] The present invention provides a fast and efficient manufacturing method for the grounding device of the mobile field system, which is to solve the above key problems, namely: reduce equipment failures caused by high grounding resistance of the grounding grid, equipment failures caused by lightning and hidden dangers of personal safety accidents , To provide a good security guarantee for our army's "all-weather, all-region, no blind spots, no blind spots" operations. The capacitive grounding device for mobile field operations of the present invention has been applied in high-voltage laboratory grounding systems, air force radar station grounding system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com