A paper tube drying room for toy processing

A drying room and paper-using technology, which is applied in the direction of cardboard winding articles, etc., can solve the problems of uneven drying, water vapor cannot be quickly discharged, etc., and achieve the effect of drying balance, avoiding water vapor accumulation, and avoiding heat loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

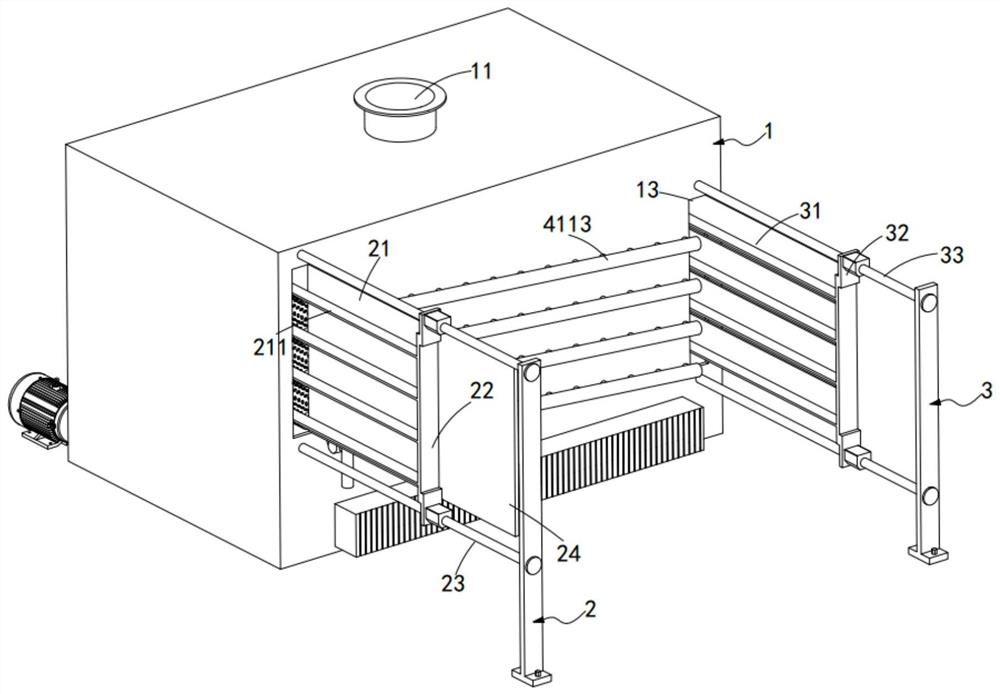

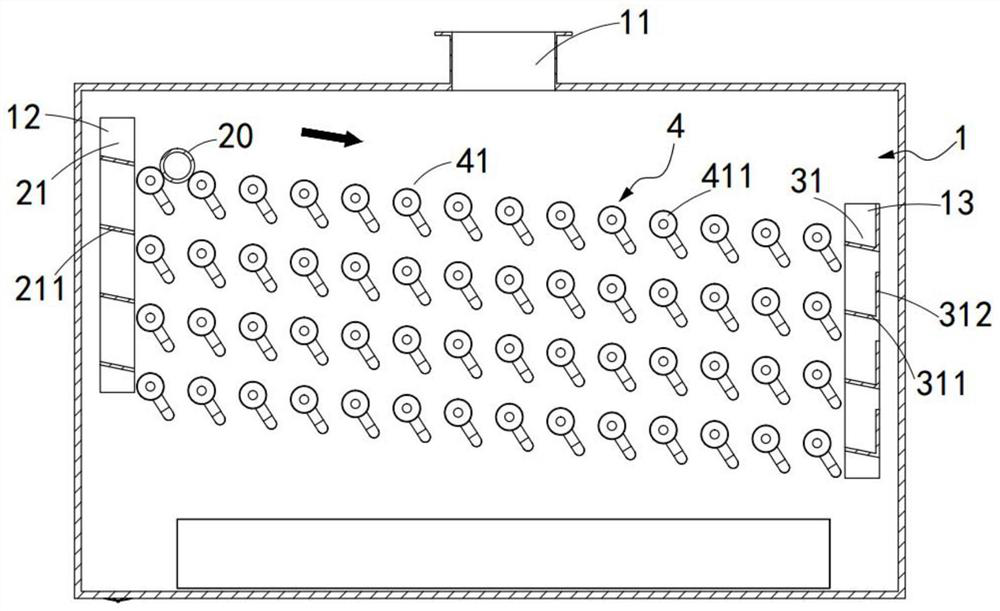

[0059] Such as Figure 1 to Figure 6 As shown, a paper tube drying room for toy processing, comprising:

[0060] Drying room 1, described drying room 1 is cuboid setting, and its top is provided with exhaust outlet 11, and exhaust outlet 11 is communicated with external environmental protection treatment device through pipeline, and is provided with exhaust fan in pipeline, and its length direction Both ends are respectively provided with a feed port 12 and a discharge port 13, and the feed port 12 is higher than the discharge port 13;

[0061] Feed device 2, described feed device 2 is arranged on described feed inlet 12 places, and it comprises some feed bins 21 that are arranged in parallel, and this feed bin 21 is horizontally arranged along the short side direction of described drying room 1, And the feeding bin 21 horizontally moves the conveying paper cylinder 20 into the drying room 1 along the direction perpendicular to the long side of the drying room 1;

[0062] Di...

Embodiment 2

[0094] Figure 12 It is a schematic structural view of Embodiment 2 of a paper tube drying room for toy processing in the present invention; as Figure 12 As shown, the parts that are the same as or corresponding to the first embodiment adopt the corresponding reference numerals of the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The second embodiment is similar to the first embodiment. figure 1 The difference of the shown embodiment one is:

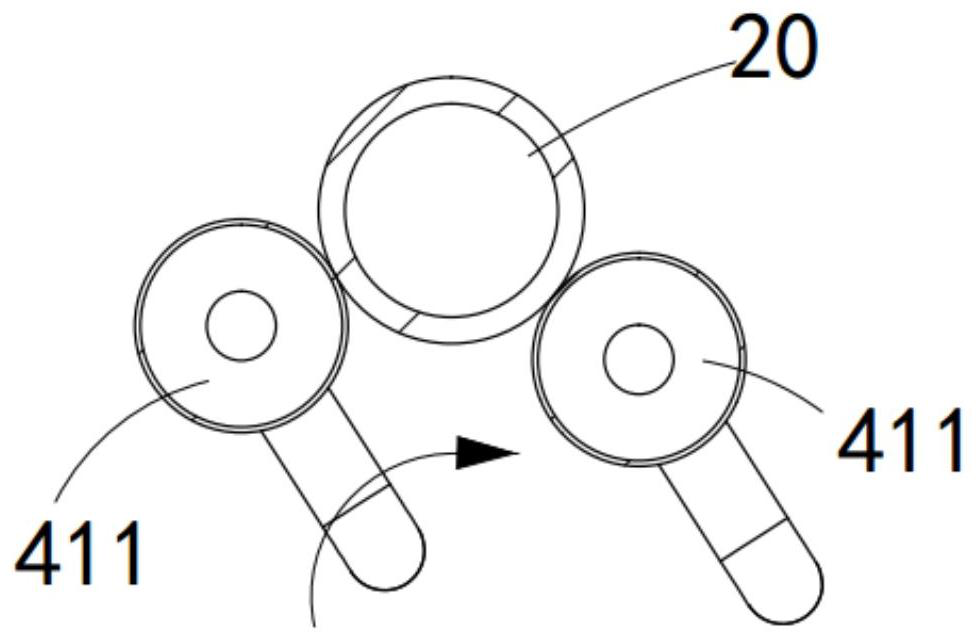

[0095] Such as Figure 12 As shown, a paper tube drying room for toy processing, a limiting rolling device 5 is arranged above the adjacent conveying rollers 411 in the same horizontal direction, and the limiting rolling device 5 includes:

[0096] A fixed mounting plate 51, the fixed mounting plate 51 is arranged horizontally, and its two ends in the length direction are fixedly connected to the drying room 1;

[0097] A limiting plate 52, the limiting plate 52 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com