Method of separating and purifying dihydromyricetin from ampelopsis grossedentata

A technology for purifying dihydromyricetin and vine tea, which is applied in the direction of organic chemistry and can solve the problems of reduced yield and low purity of dihydromyricetin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment provides a kind of dihydromyricetin, which is prepared by adopting the following method of extracting dihydromyricetin from vine tea, and its specific process is as follows:

[0042] S11, crush the rattan tea and pass it through a 40-mesh sieve, and collect the sifted rattan tea powder.

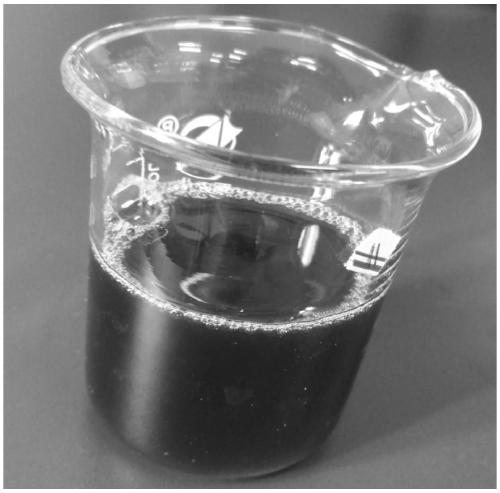

[0043] S12. Take 100g of the above vine tea powder and add 2000ml of water to mix evenly, then stir and extract at 90°C for 1h, and centrifuge to obtain a water extract, such as figure 1 shown.

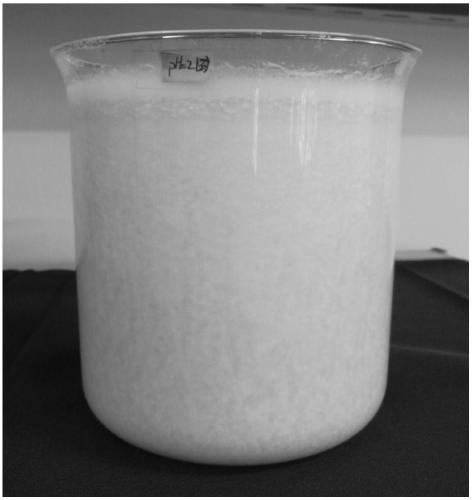

[0044] S13. Adsorb the water extract with D-101 macroporous resin, heat it at 45°C for 1.5h and then cool it to 25°C, then wash the macroporous resin twice with water three times the volume of the macroporous resin, and then use macroporous resin The mass percentage of 3 times of the volume of the porous resin is 40% ethanol solution to wash the macroporous resin 2 times, and finally the macroporous resin is washed with 90% ethanol solution of 3 times of the mass percentage of t...

Embodiment 2

[0050] This embodiment provides a kind of dihydromyricetin, which is prepared by adopting the following method of extracting dihydromyricetin from vine tea, and its specific process is as follows:

[0051] S21, crush the rattan tea and pass it through a 50-mesh sieve, and collect the sifted rattan tea powder.

[0052] S22. Take 100 g of rattan tea powder and 2200 ml of water and mix evenly, then stir and cold-extract at 85° C. for 1.5 h, and filter to obtain a water extract.

[0053] S23. Use the macroporous resin to adsorb the water extract, adsorb at 40°C for 2h, then cool to 30°C, then wash the macroporous resin twice with water twice the volume of the macroporous resin, and then use twice the volume of the macroporous resin Wash the macroporous resin twice with 40% ethanol solution by mass percentage, and finally wash the macroporous resin with 90% ethanol solution with 4 times the mass percentage of the macroporous resin, and collect 90% ethanol washing solution to obtain...

Embodiment 3

[0058] This embodiment provides a kind of dihydromyricetin, which is prepared by adopting the following method of extracting dihydromyricetin from vine tea, and its specific process is as follows:

[0059] S31, crush the rattan tea and pass it through a 60-mesh sieve, and collect the sifted rattan tea powder.

[0060] S32. Take 100 g of rattan tea powder and 2400 ml of water and mix evenly, then stir and condense at 80° C. for reflux for 1 hour, and filter to obtain a water extract.

[0061] S33. Use the macroporous resin to adsorb the water extract, adsorb at 50° C. for 1 hour, then cool to 28° C., then wash the macroporous resin once with water 3 times the volume of the macroporous resin, and then use 3 times the volume of the macroporous resin Wash the macroporous resin once with 35% ethanol solution by mass percentage, and finally wash the macroporous resin with 80% ethanol solution 5 times the mass percentage of the macroporous resin, and collect the 80% ethanol washing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com