Mask plate group for evaporation

A mask and evaporation technology, applied in vacuum evaporation coating, sputtering coating, ion implantation coating and other directions, can solve the problems affecting the realization of full screen, unable to meet the camera, unable to fix and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

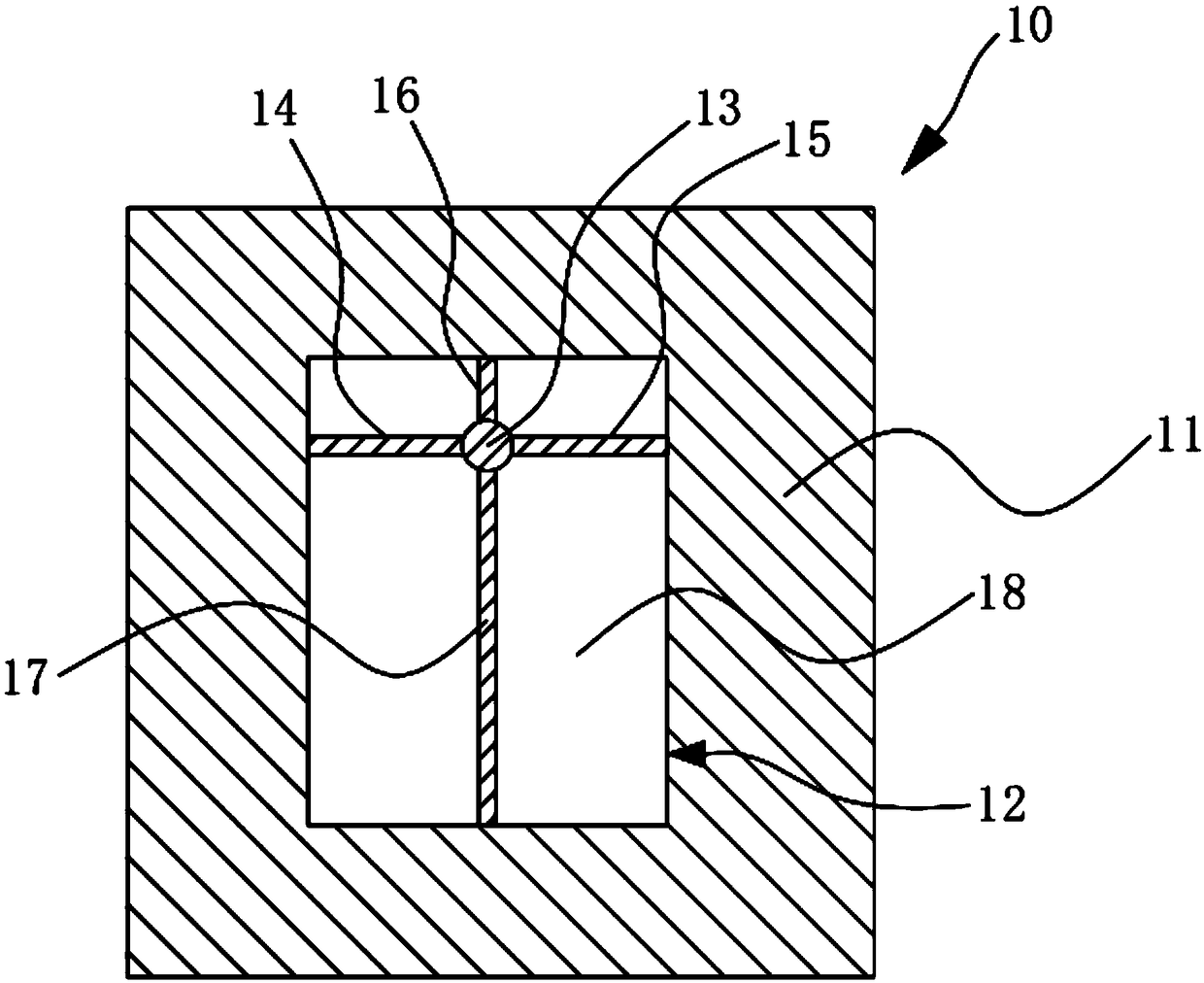

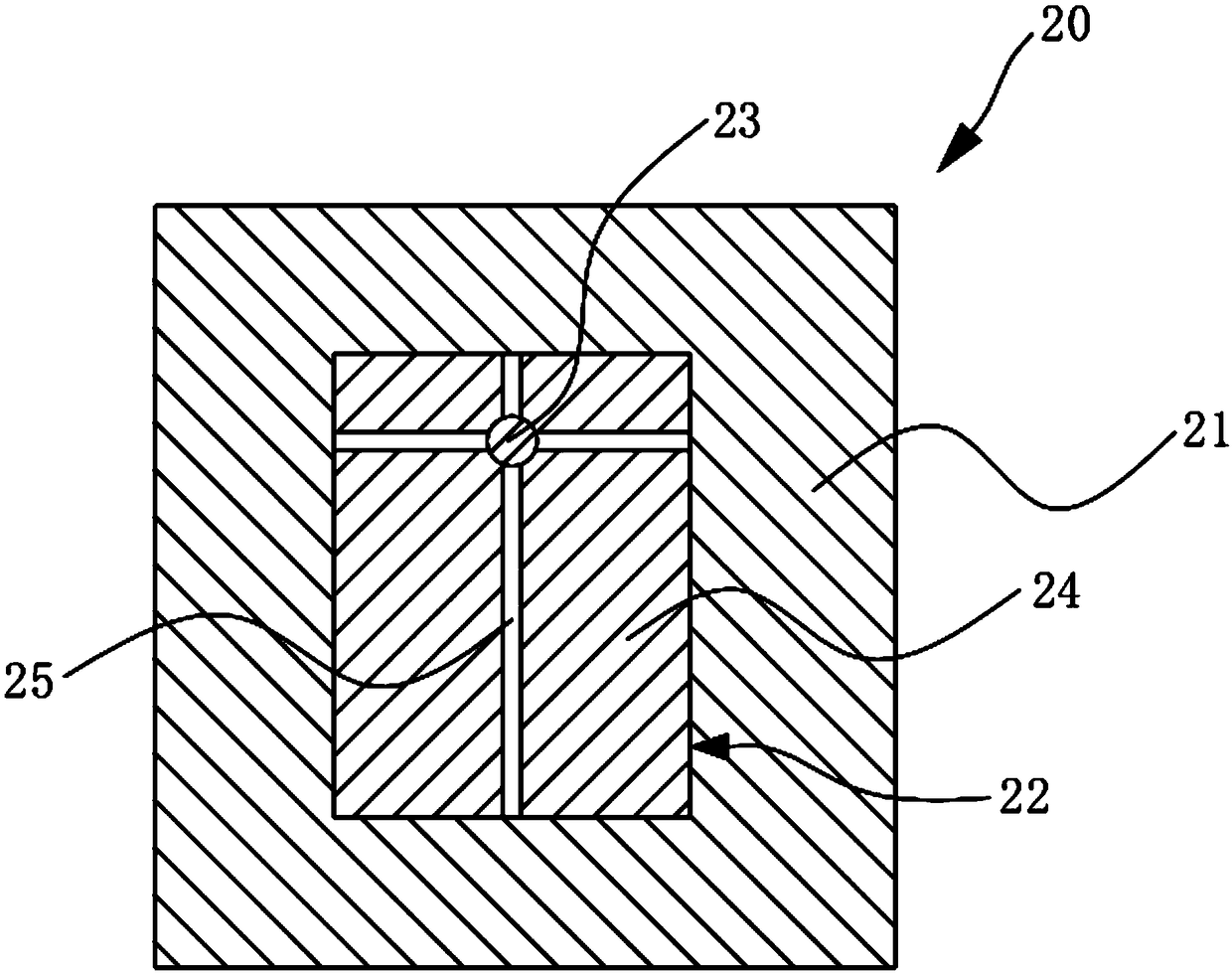

[0036] Such as figure 1 and figure 2 As shown, it is a schematic diagram of a matching mask used in the present invention. This embodiment provides a mask set, which includes two matching used masks, namely a first mask 10 and a second mask 20 .

[0037] Among them, such as figure 1 The first mask 10 shown includes a mask body 11 and an opening area 12, and the opening area 12 is provided with a shielding part 13, a first connecting piece 14, a second connecting piece 15, a third connecting piece 16, a second connecting piece Four connectors 17, and an evaporation area 18.

[0038] Wherein, one end of the first connecting piece 14, the second connecting piece 15, the third connecting piece 16, and the fourth connecting piece 17 are all connected to the shielding portion 13, and the opposite ends are connected to the shielding portion 13. The mask body 11 is connected. The shielding part 13 is fixed by four connecting pieces.

[0039] The first connecting part 14, the sec...

Embodiment 2

[0049] Such as figure 1 , 3 , 4, in order to carry out the evaporation process more stably, the evaporation can be divided into three times, the mask set provided in this embodiment includes three matching masks, namely the first mask 10, the second mask 30 and the third mask 40 .

[0050] The first mask provided in this embodiment has the same structure as the first mask provided in Embodiment 1 above, and details are not repeated here.

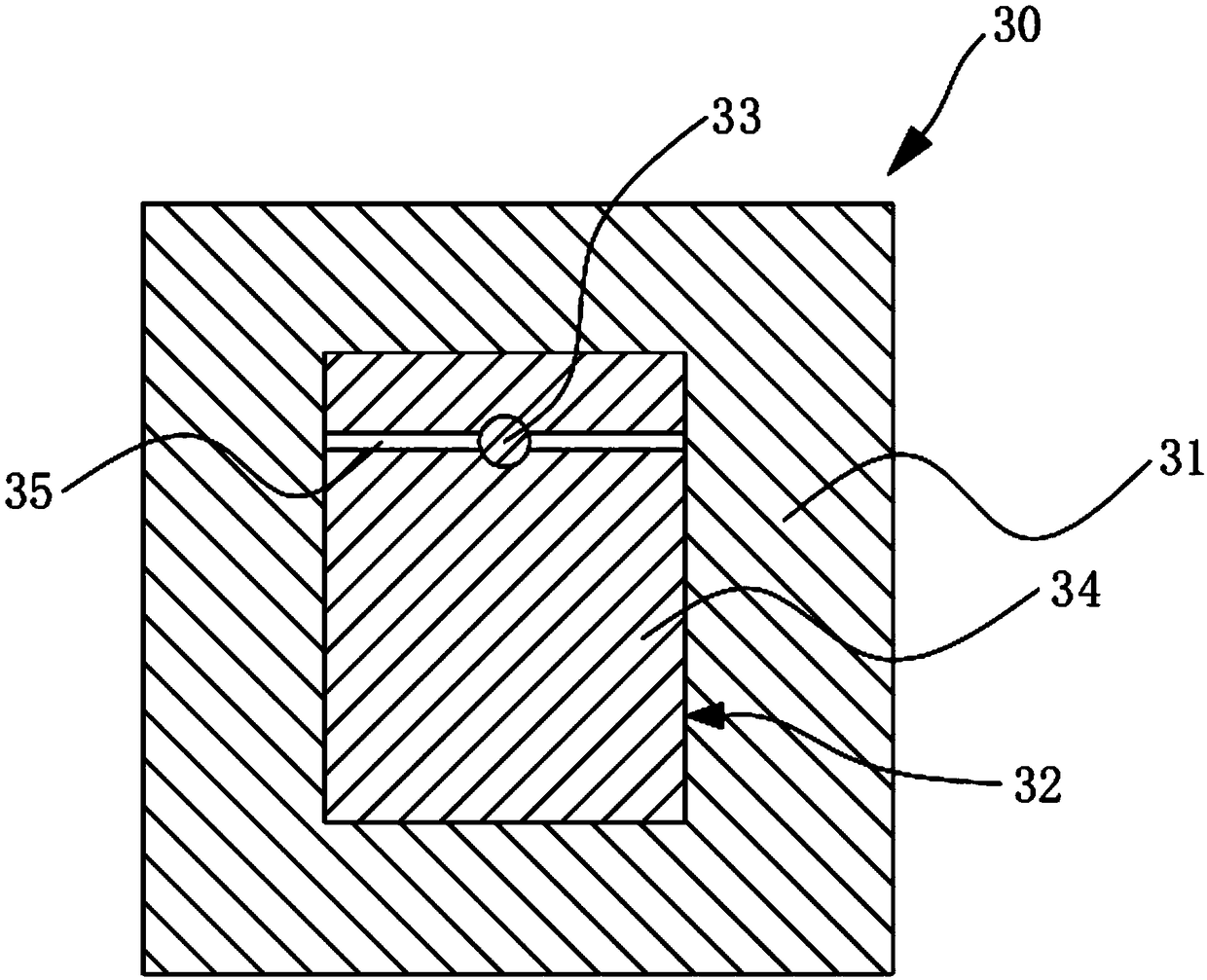

[0051] Such as image 3 As shown, the second mask 30 includes a mask body 31 and an opening area 32 , and the opening area 32 is provided with a shielding portion 33 , two connecting pieces 34 , and an evaporation area 35 .

[0052] Wherein, the two connecting pieces 34 are respectively located on two sides of the shielding portion 33 to connect and fix the shielding portion 33 with the mask body 31 .

[0053] The evaporation area 35 of the second mask plate 30 is divided into two second sub-evaporation areas by the shielding portion 33 ...

Embodiment 3

[0059] Such as figure 1 , Figure 5-8 As shown, the mask set provided in this embodiment includes five matching masks, namely the first mask 10, the second mask 50, the third mask 60, the fourth mask 70, and the fifth mask 80.

[0060] When performing evaporation, use the first mask plate 10 to perform the first evaporation, since the areas corresponding to the four connectors of the first mask plate 10 are blocked, the evaporation cannot be completed, in order to further fix For the shielding part, the subsequent coating can be divided into four evaporation processes. The second mask 50, the third mask 60, the fourth mask 70, and the fifth mask 80 provided in this embodiment are respectively for the first The regions of the first connector 14 , the second connector 15 , the third connector 16 , and the fourth connector 17 of the mask plate 10 that are not vapor-deposited are designed.

[0061] Such as Figure 5 As shown, the second mask 50 includes a mask body 51 and an o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com