Concrete crack control construction method combining jump warehouse method with expansion reinforcing band

A technology of expanding reinforcement strips and expansive concrete, which is applied in infrastructure engineering, artificial islands, water conservancy projects, etc., can solve problems such as difficult handling of post-casting strips, affecting the quality of post-casting strips, and affecting construction progress, so as to reduce and control leakage Hidden dangers, beneficial to resist temperature difference cracks, and avoid the effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with embodiment.

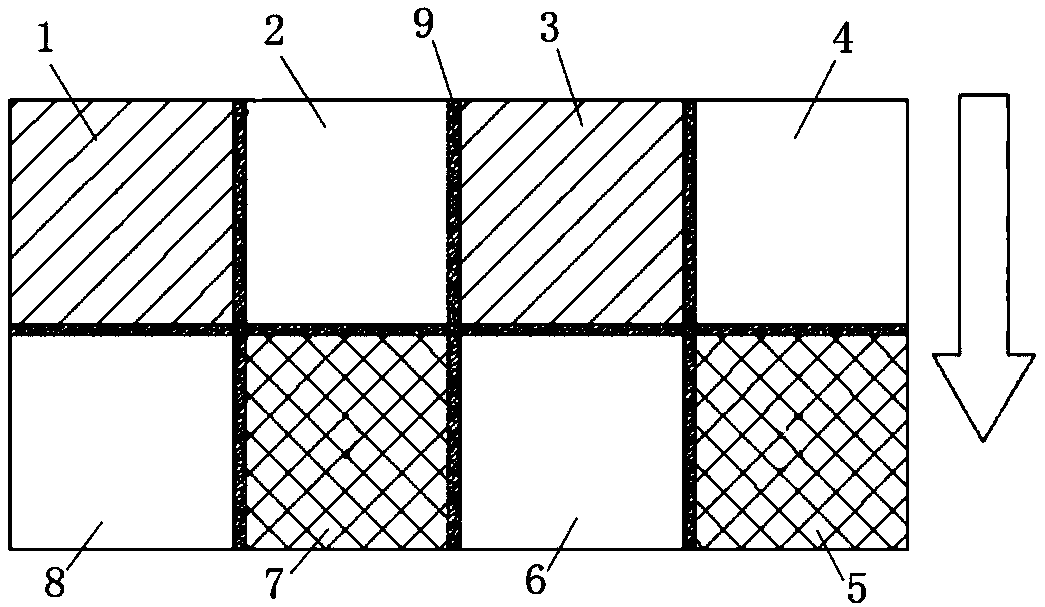

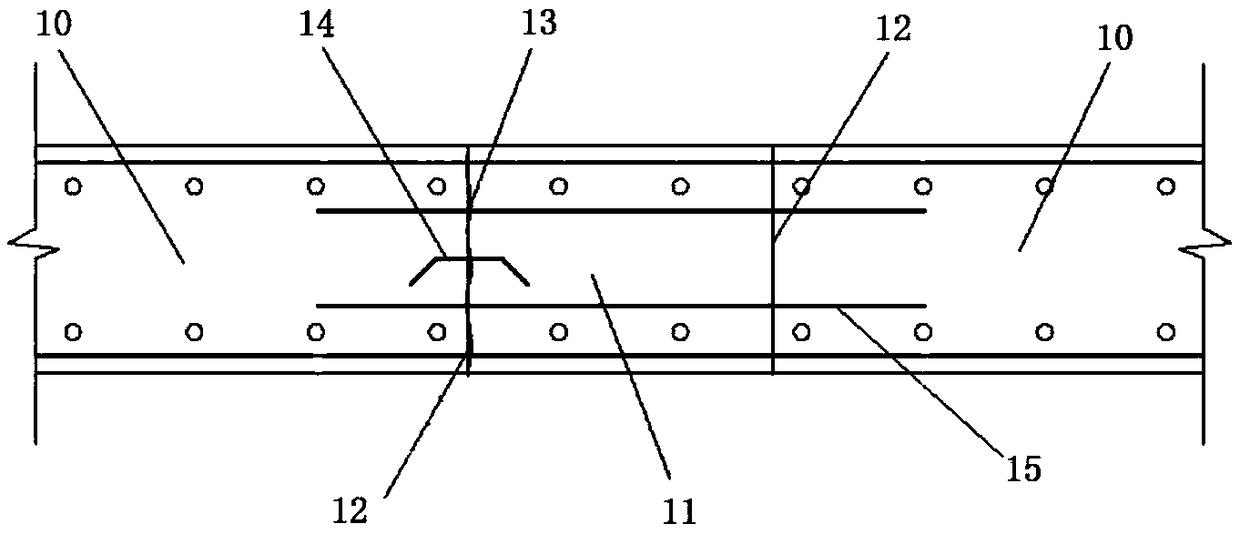

[0014] Such as figure 1 and figure 2 Shown, the technical scheme that concrete construction method of the present invention adopts is as follows:

[0015] (1) Warehouse settings

[0016] According to the technical principle of "block planning, block construction, layered pouring, and integral molding", the sub-silos are set up, and the location of the maximum structural stress and deformation of the basement is considered. The construction should not be less than 7 days, that is, the length and width of each warehouse should be 40-50m, and the numbering along any direction should be done. Add small-diameter, high-density additional ribs to increase the crack resistance of concrete. Such as figure 1 As shown, the present invention divides the area into 8 blocks, which are named T1 block 1, T2 block 2, T3 block 3, T4 block 4, T5 block 5, T6 block 6, and T7 block Block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com