Efficient vortex type gas stove combustor

A vortex, gas stove technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problems of insufficient dispersion of fire power, insufficient combustion of gas, low thermal efficiency, etc., to achieve concentrated fire power, reduce waste, promote full burn effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

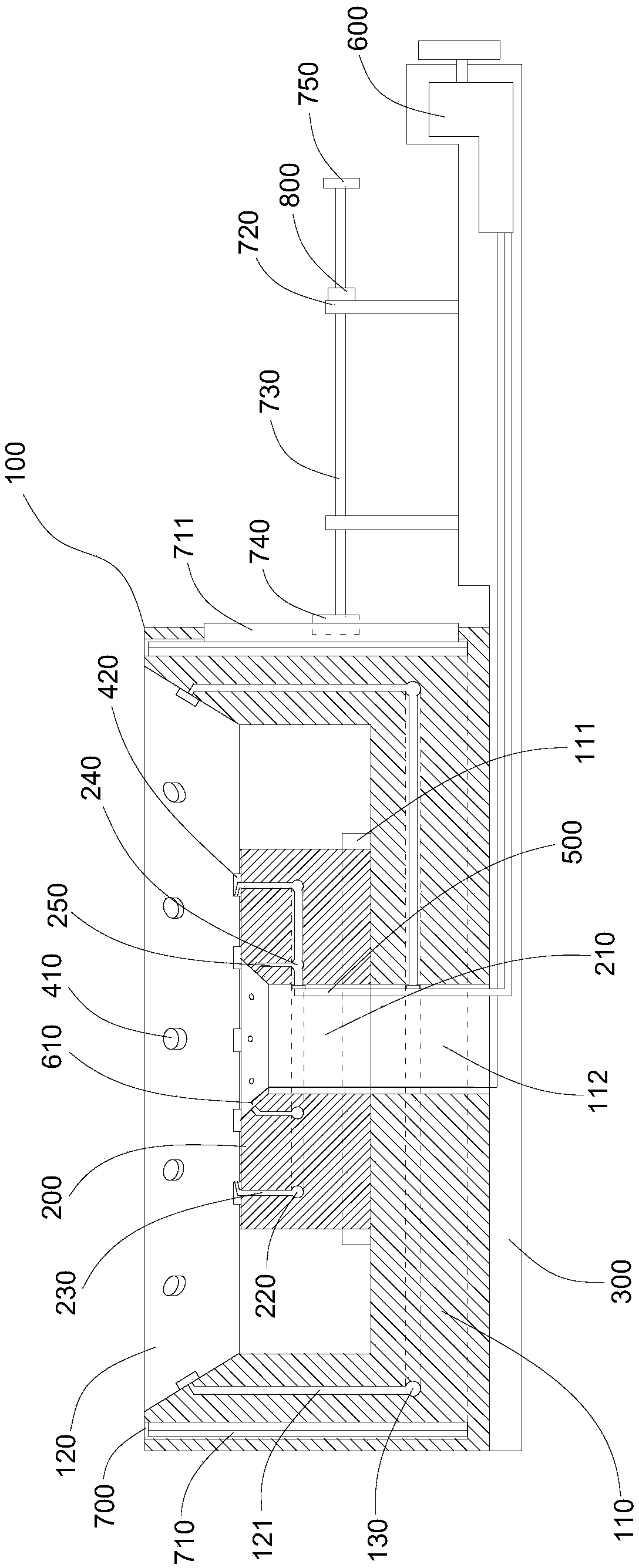

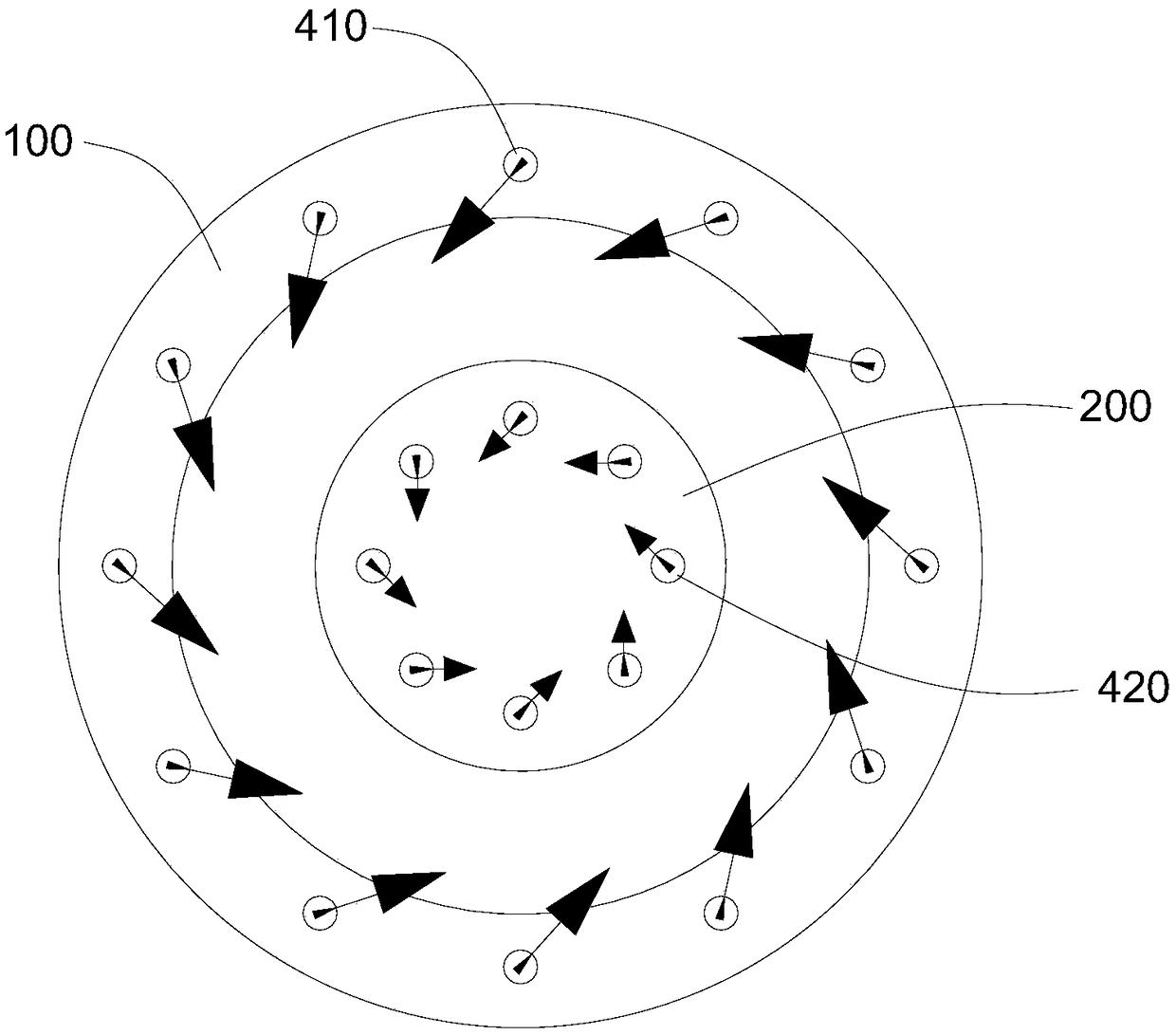

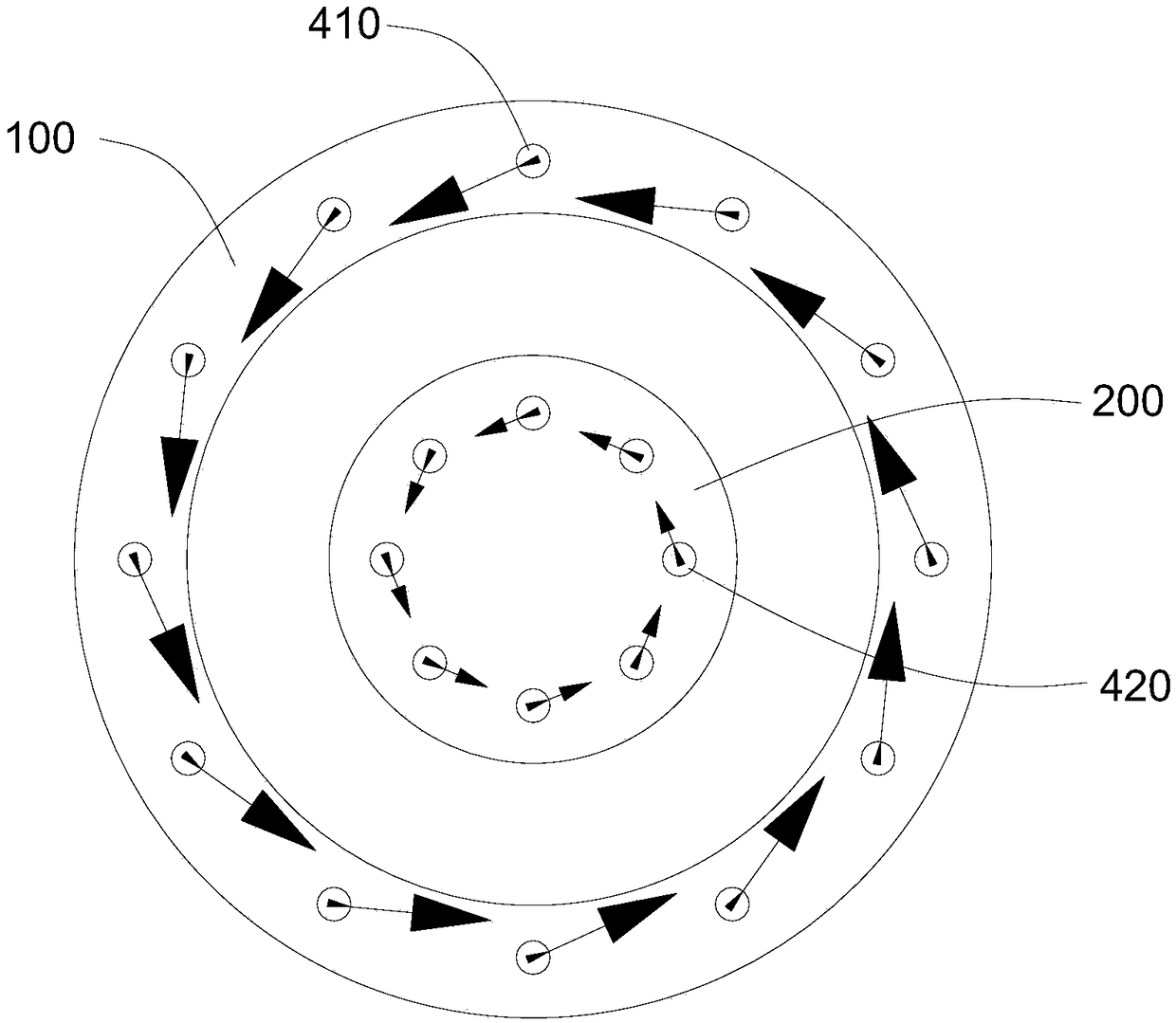

[0027] Such as figure 1 As shown, a high-efficiency vortex gas stove burner is disclosed in a specific embodiment of the present invention, including a base 300 and a first gas seat 100 fixed on the top surface of the base 300, as shown in Figure 4 , Figure 5 As shown, the first air seat 100 includes a disc seat 110 fixedly connected to the base 300 and a ring body 120 fixedly arranged on the edge of the top surface of the disc seat 110, the ring body 120 and the disc seat 110 As an integral structure, the top surface of the disc seat 110 is fixedly provided with a connecting ring 111, the inner wall of the connecting ring 111 is provided with threads, and a second air seat 200 is provided above the disc seat 110, and the second air seat 200 The axis of the disk base 110 coincides with the axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com