Single-axis test automatic strain measuring device and method based on computer vision

A computer vision, uniaxial test technology, applied in the field of geotechnical engineering, can solve the problems of less research on the influence of correction area, lack of testing equipment for testing unconfined strength radial strain, etc., to achieve low environmental requirements and improve measurement speed The effect with precision and simple light path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

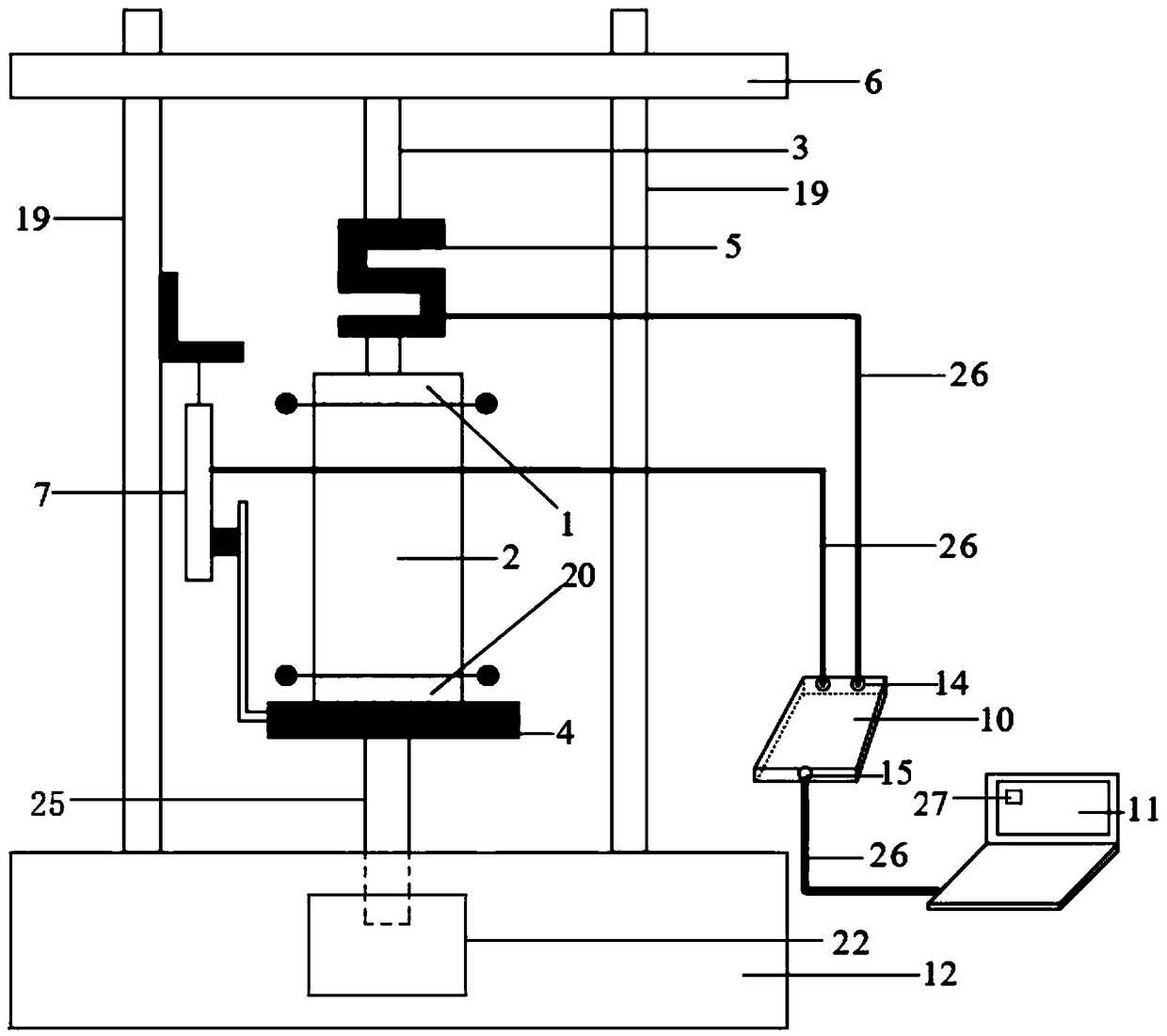

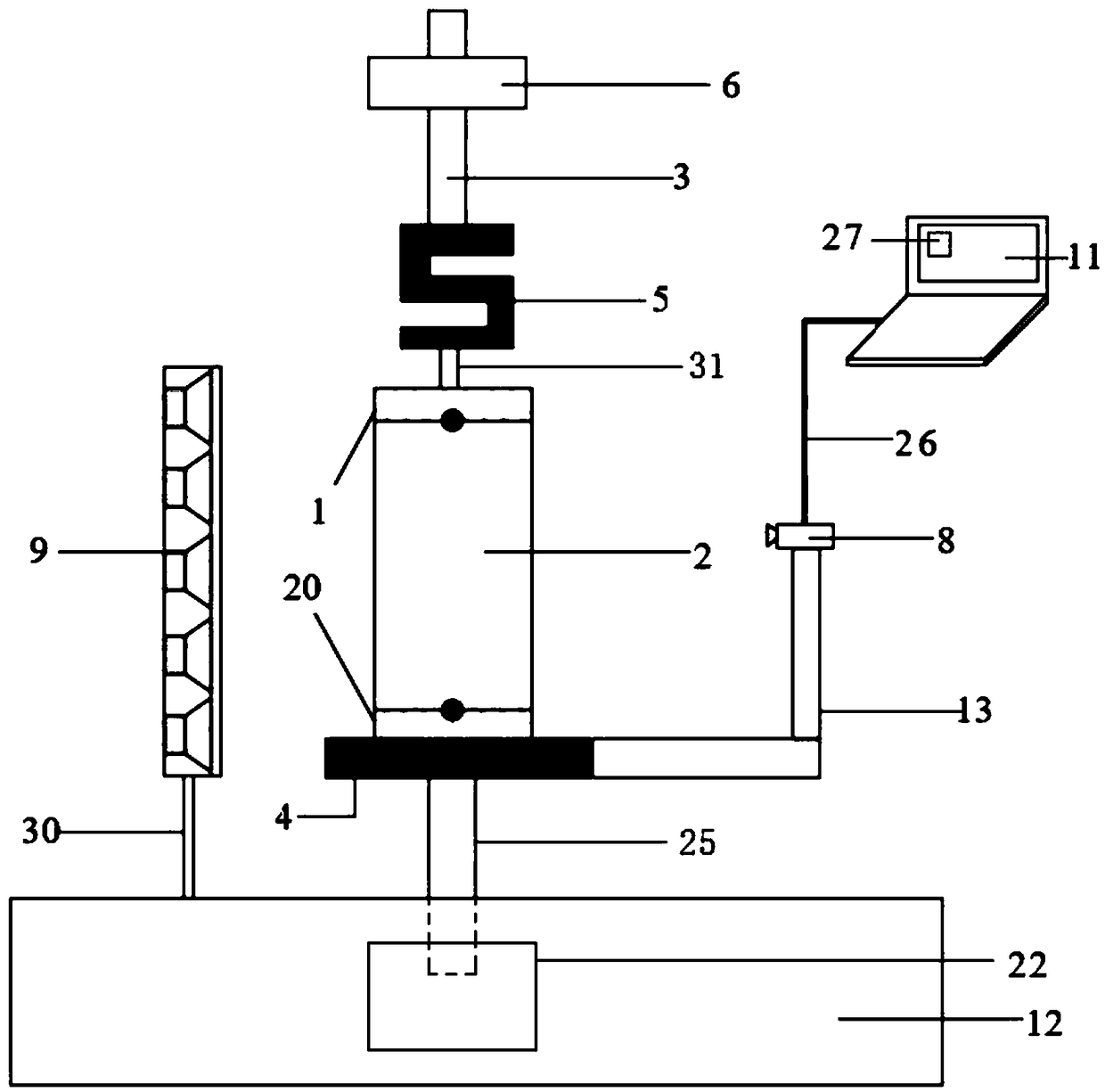

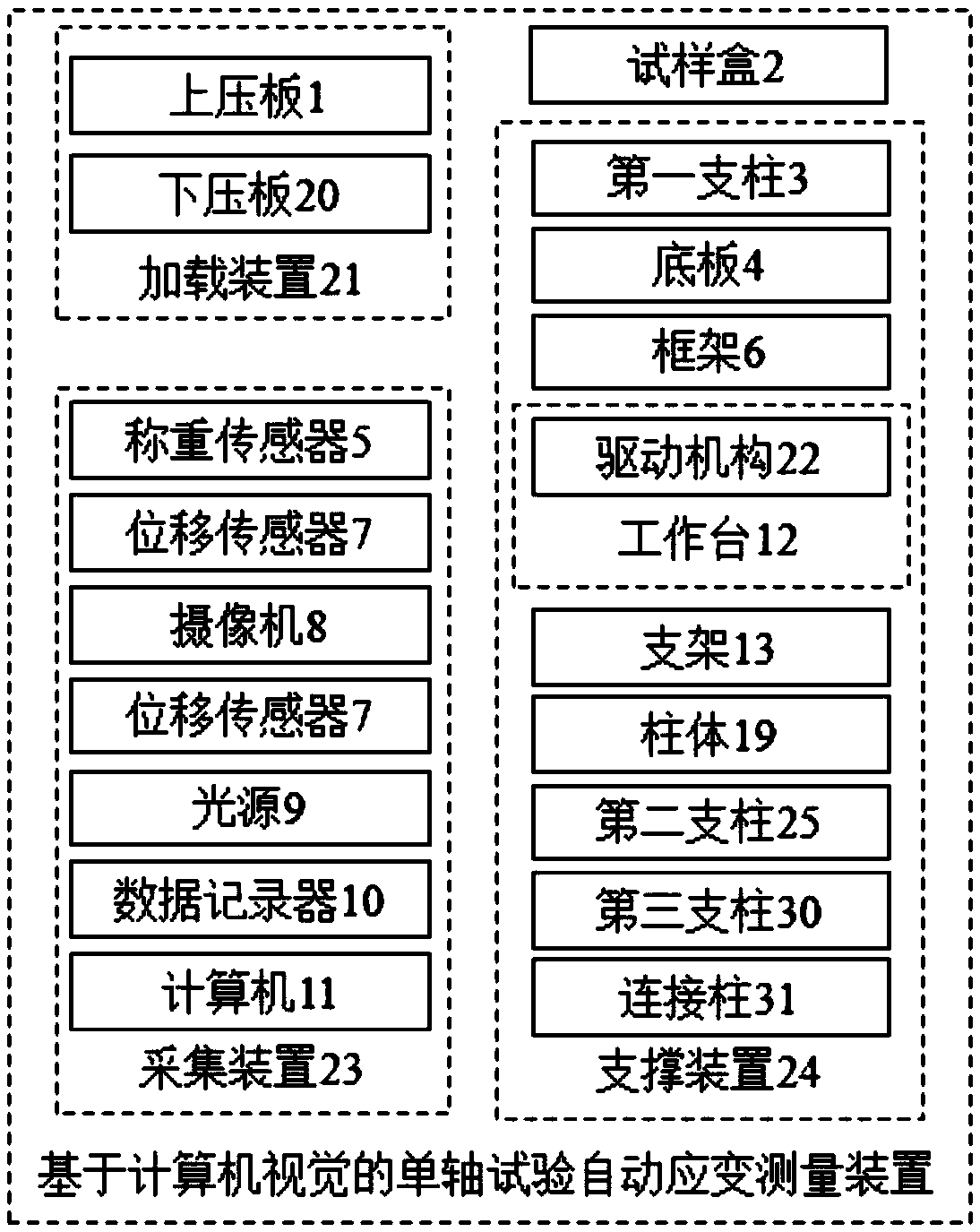

[0031] Such as Figure 1-3 As shown, the embodiment of the present invention discloses a computer vision-based uniaxial test automatic strain measurement device, including a loading device 21, a sample box 2, an acquisition device 23, and a support device 24, and the loading device 21 includes an upper platen 1, the lower platen 20, the acquisition device 23 includes a load cell 5, a displacement sensor 7, a video camera 8, a light source 9, a data recorder 10 and a computer 11, and the support device 24 includes a first pillar 3, a base plate 4, a frame 6. Workbench 12 , bracket 13 , column 19 , second support 25 , third support 30 and connecting column 31 .

[0032] The workbench 12 is placed on a fixed operating plane, and a drive mechanism 22 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com