Fabric tightness detecting apparatus

A detection device and a technology for fabric tightness, which are applied in the field of fabric tightness detection devices, can solve the problems of large difference in yarn bulkiness, large influence of length relationship, high labor intensity, etc., so as to improve detection effect and stability. And the effect of good reliability and less detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments involved in the present invention will be described in further detail below in conjunction with the accompanying drawings.

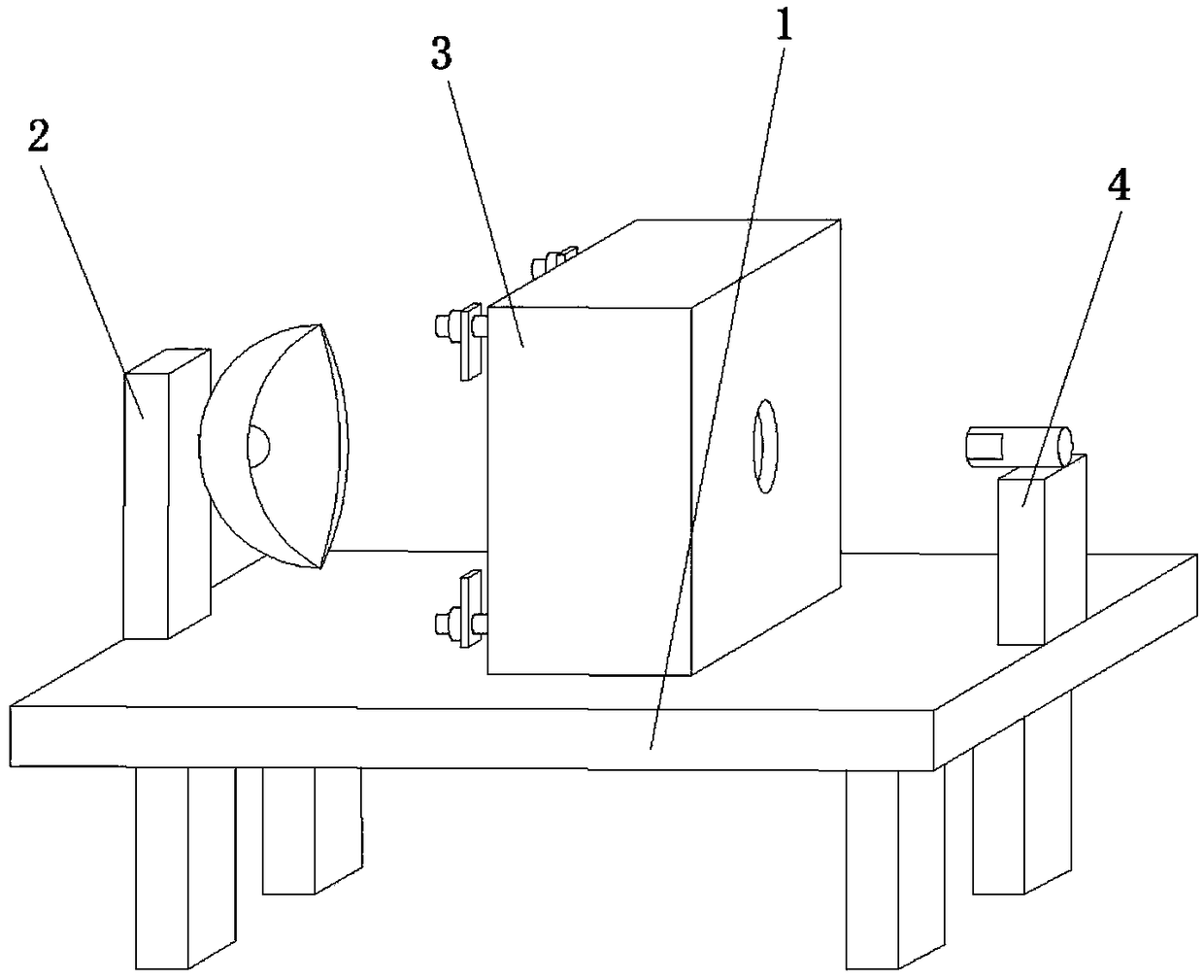

[0022] combine figure 1 , a fabric tightness detection device, including a device body, the device body is connected with an external PLC industrial computer for communication, the device body includes a table body 1, and also includes a light source mechanism 2, a test box 3 and a light receiving mechanism arranged on the table body 1 4. The light source mechanism 2 is located on one side of the top of the table body 1, the light receiving mechanism 4 is located on the other side of the top of the table body 1, the test box 3 is located between the light source mechanism 2 and the light receiving mechanism 4, the light source mechanism 2, the test box 3 and the light The central axis of the receiving mechanism 4 is on the same vertical plane.

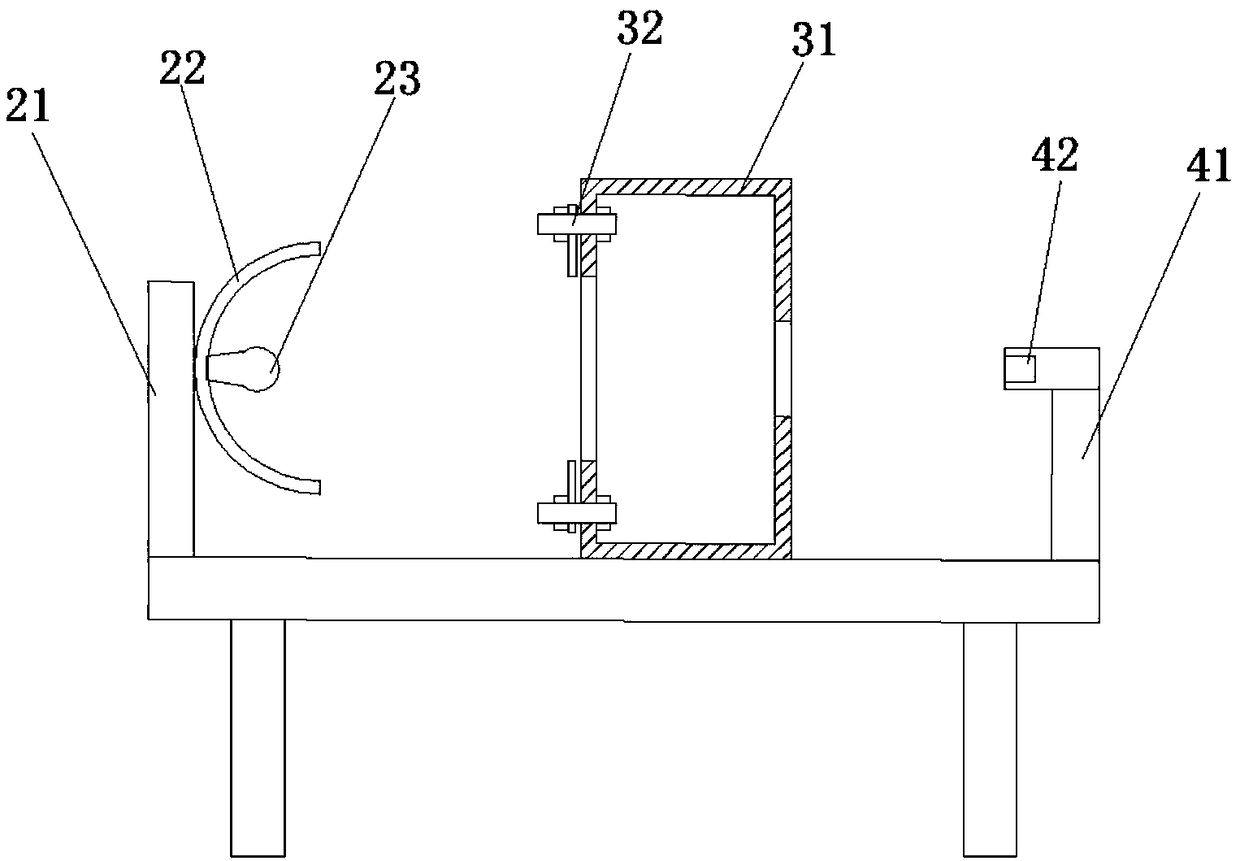

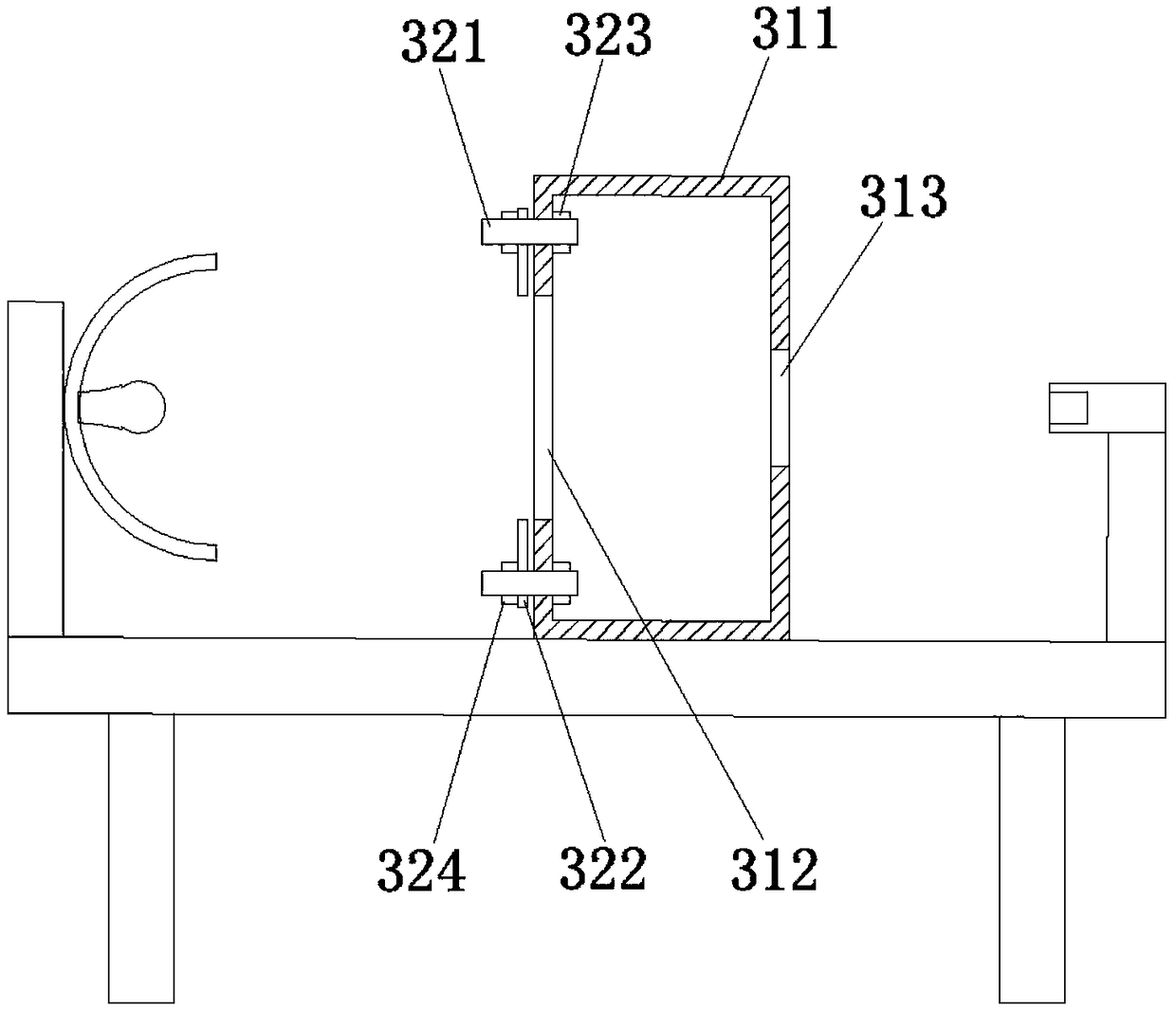

[0023] combine figure 2 The light source mechanism 2 includes a support rod 21 fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com