Clamp used for numerical control lathe for machining parts in irregular shapes

A CNC lathe, irregular technology, used in metal processing machinery parts, manufacturing tools, metal processing equipment and other directions, can solve the problems of unsuitable parts, unsuitable CNC machine tools, etc., to achieve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

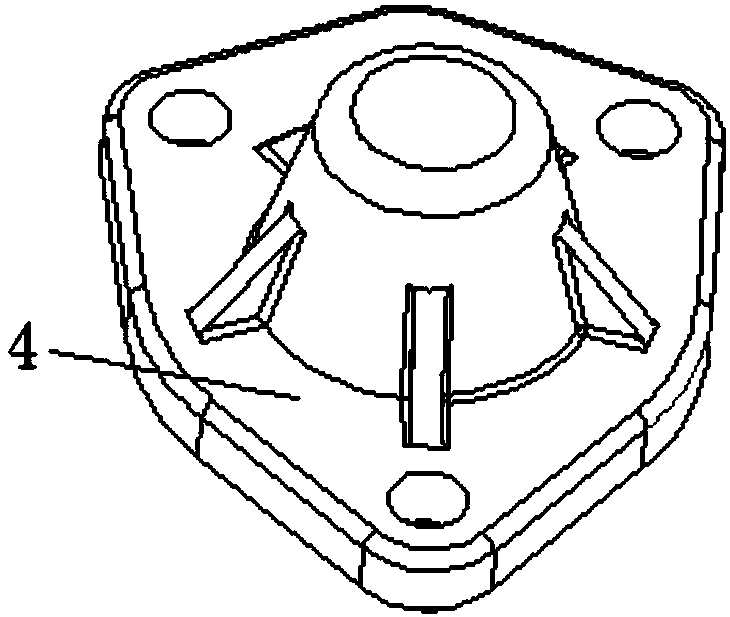

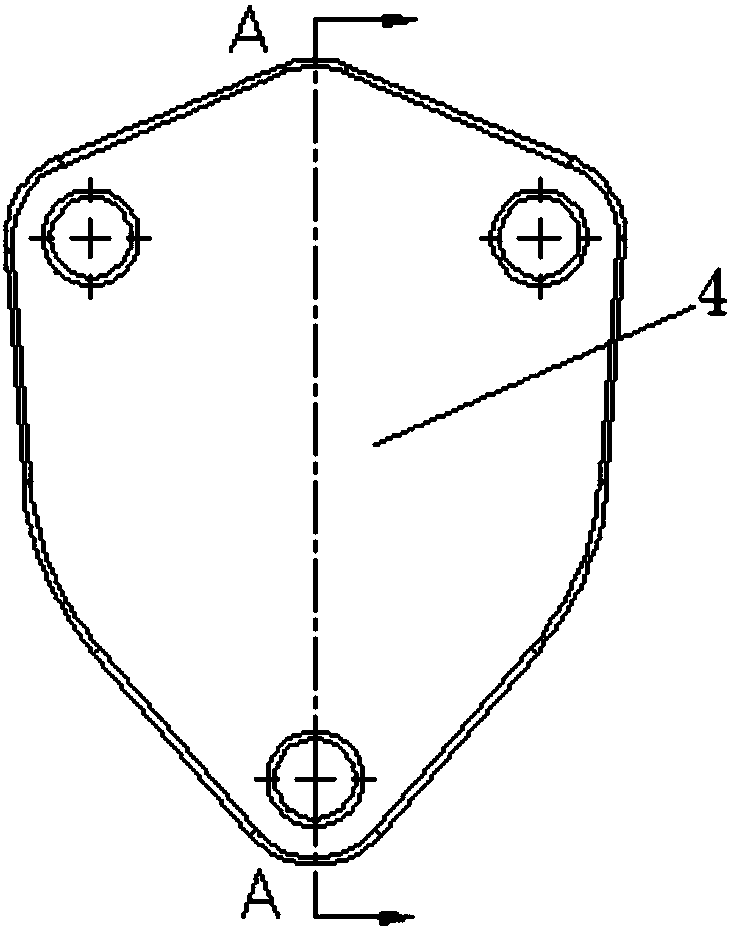

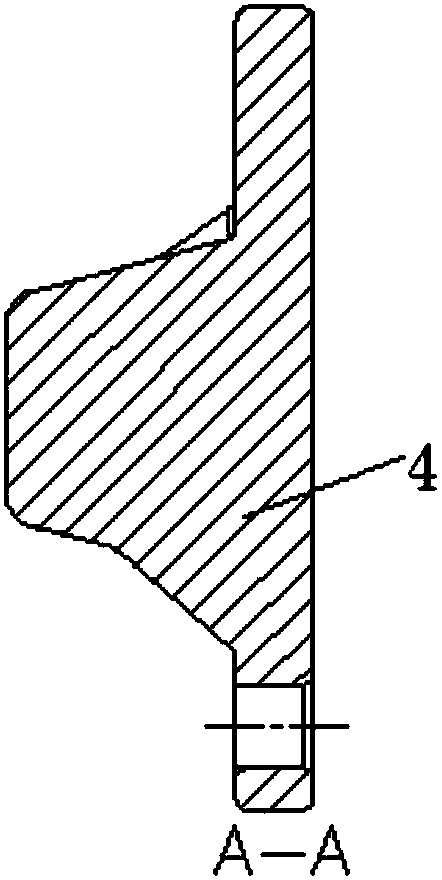

[0035] Irregular shape parts to be processed 4 such as figure 1 , 2 , as shown in 3, for figure 1 , 2 3. For cast aluminum parts with extremely irregular shapes as shown in 3, especially a tapered hole is processed in the middle of the part, and a tapered annular spiral oil groove is processed in the hole. The precision and surface roughness of the tapered hole are very high. The feature of the tapered annular spiral oil groove must be processed on a CNC lathe, and the traditional three-jaw or four-jaw chuck on a CNC lathe cannot meet the clamping requirements at all.

[0036] like Figure 4 , Figure 5 As shown, a fixture for CNC lathe processing parts with irregular shapes, including a supporting part, a positioning part and a fixing part, the supporting part includes a supporting base 1, a supporting plate 5 and a supporting panel 7, and the positioning part includes a positioning pin 2 and a shaft Shoulder positioning screw 3, the fixed parts include locking bolt 6 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com