A kind of preparation method of polyester nylon composite elastic fiber

A composite technology of elastic fiber and polyester nylon, which is applied in the field of spinning to achieve good crimp elasticity and improved compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A preparation method of polyester nylon composite elastic fiber, comprising the following steps:

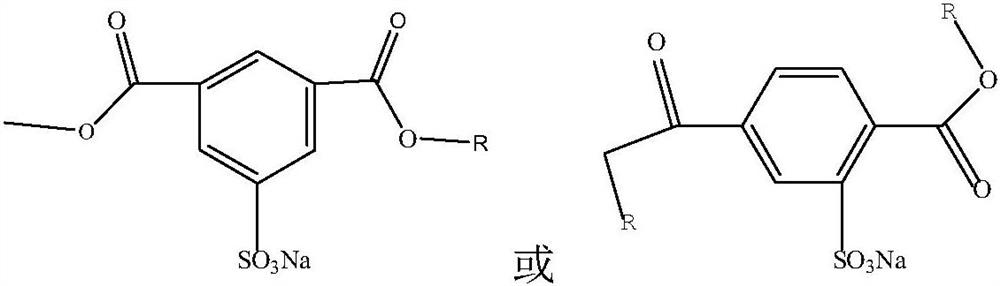

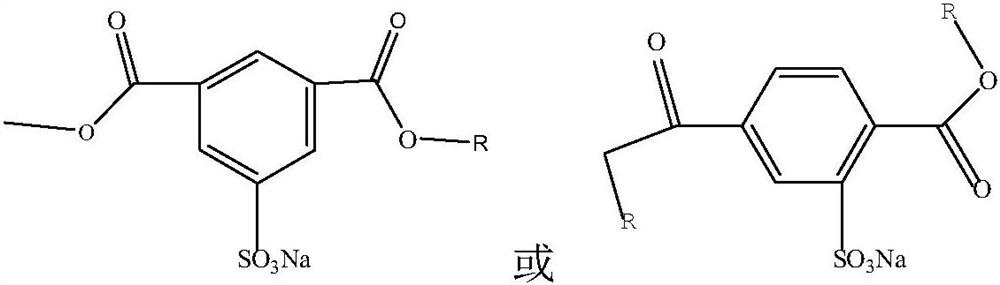

[0031] 1) Adding a third monomer with a total monomer amount of 1.5 to 2.5 mol / % to polyester monomers to synthesize modified polyester chips.

[0032] 2) Drying the modified polyester slices and nylon 6 slices respectively. The drying temperature of the modified polyester chips is 120-140° C., the drying time is 20 hours, and the water content of the resin after drying treatment is less than 30 ppm. The drying temperature of nylon 6 chips is 90-100°C, the drying time is 24 hours, and the water content of the resin after drying treatment is less than 100ppm.

[0033] Blend the dried modified polyester chips and nylon 6 chips, wherein the intrinsic viscosity of the modified polyester chips is 0.50-0.65dl / g, the relative viscosity of the nylon 6 chips is 2.47-2.52, the modified polyester chips and nylon The mass ratio of slices is 80:20-60:40.

[0034] Polyester and nylon...

Embodiment 1

[0041] A preparation method of polyester nylon composite elastic fiber, comprising the following steps:

[0042] 1) Add a third monomer of 2 mol / % total monomer amount to the polyester monomer, the third monomer is sodium ethylene glycol sulfonate isophthalate, and synthesize modified polyester chips.

[0043] 2) Drying the modified polyester slices and nylon 6 slices respectively. The drying temperature of the modified polyester chips is 130°C, the drying time is 20 hours, and the water content of the resin after drying treatment is less than 30ppm. The drying temperature of nylon 6 chips is 95°C, the drying time is 24 hours, and the water content of the resin after drying treatment is less than 100ppm.

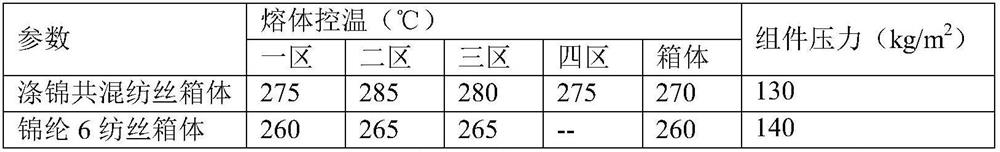

[0044] The modified polyester chips and nylon 6 chips that have been dried are blended for 3 minutes, wherein the intrinsic viscosity of the modified polyester chips is 0.50dl / g, the relative viscosity of the nylon 6 chips is 2.48, and the quality of the modified polyester ...

Embodiment 2

[0051] A preparation method of polyester nylon composite elastic fiber, comprising the following steps:

[0052] 1) Add a third monomer with a total monomer amount of 2 mol / % to the polyester monomer, the third monomer is sodium ethylene glycol phthalate sulfonate, and synthesize modified polyester chips.

[0053] 2) Drying the modified polyester slices and nylon 6 slices respectively. The drying temperature of the modified polyester chips is 130°C, the drying time is 20 hours, and the water content of the resin after drying treatment is less than 30ppm. The drying temperature of nylon 6 chips is 100°C, and the drying time is 24 hours. After drying, the water content of the resin is less than 100ppm.

[0054] The modified polyester chips and nylon 6 chips that have been dried are blended for 3 minutes, wherein the intrinsic viscosity of the modified polyester chips is 0.52dl / g, the relative viscosity of the nylon 6 chips is 2.48, and the quality of the modified polyester chip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com