Short fiber mixing device for silk fabrics

A mixing device and short fiber technology, which is applied in the directions of fiber mixing, fiber processing, textiles and papermaking, etc., can solve the problems of easy adhesion of short fibers, difficult to clean, slow mixing speed, etc., and achieve good mixing effect and mixing. Good effect and fast mixing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the examples, but not as a basis for limiting the present invention.

[0019] Example.

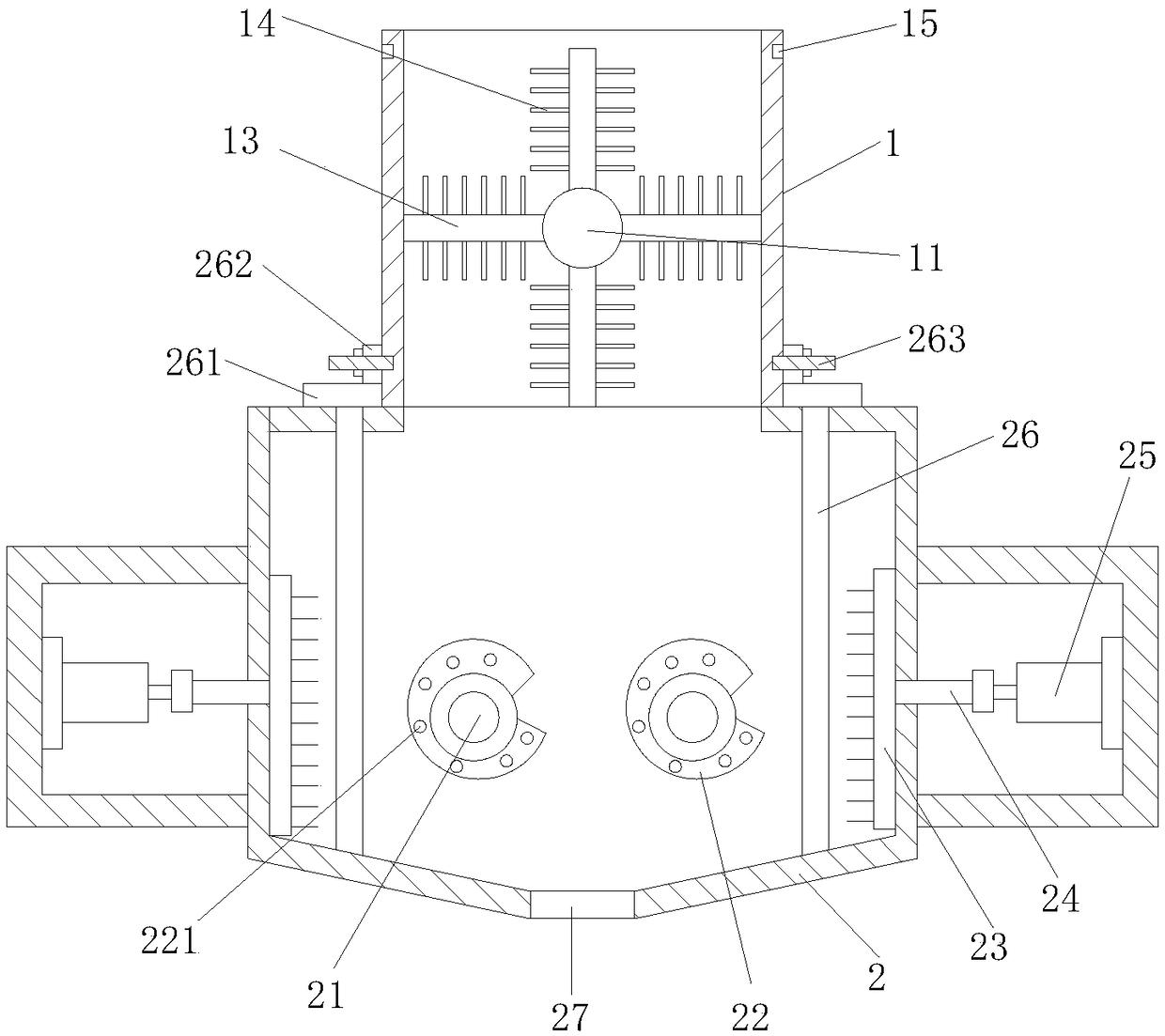

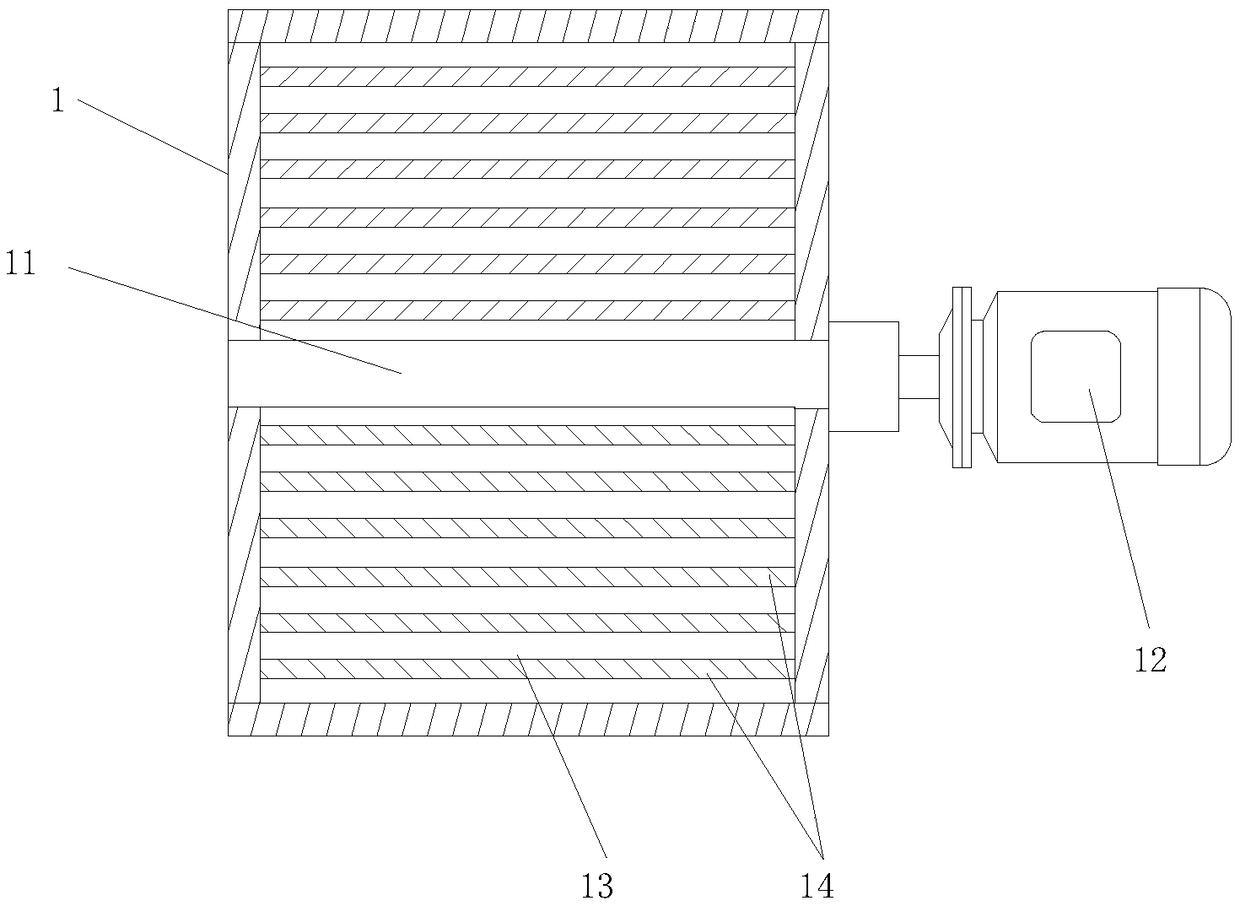

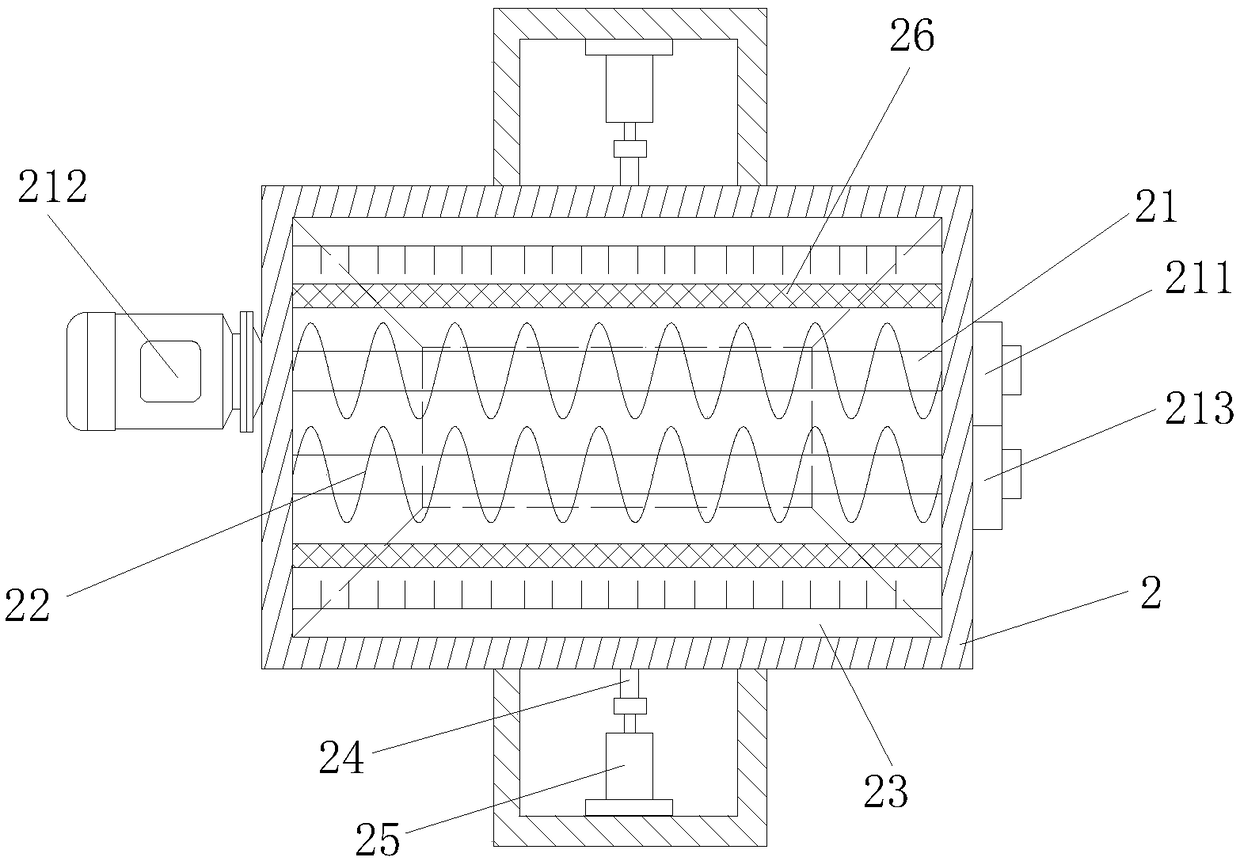

[0020] like Figure 1-3 As shown, a short fiber mixing device for silk fabrics comprises a feeding box 1, the outlet of the feeding box 1 is provided with a mixing box 2, and the inside of the feeding box 1 is provided with a feed rod 11 distributed laterally, and The two ends of feed rod 11 are connected with the inner wall of feed box 1 in rotation, and one end of feed rod 11 is connected with rotating motor 12, and the peripheral surface of feed rod 11 is evenly provided with several feed plates 13; 2 is provided with a pair of left and right parallel mixing rollers 21, the surrounding surface of the mixing rollers 21 is provided with S-shaped mixing blades 22, and the mixing box 2 is also equipped with cleaning brushes corresponding to the mixing rollers 21 one by one. 23. The outer surface of the cleani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com