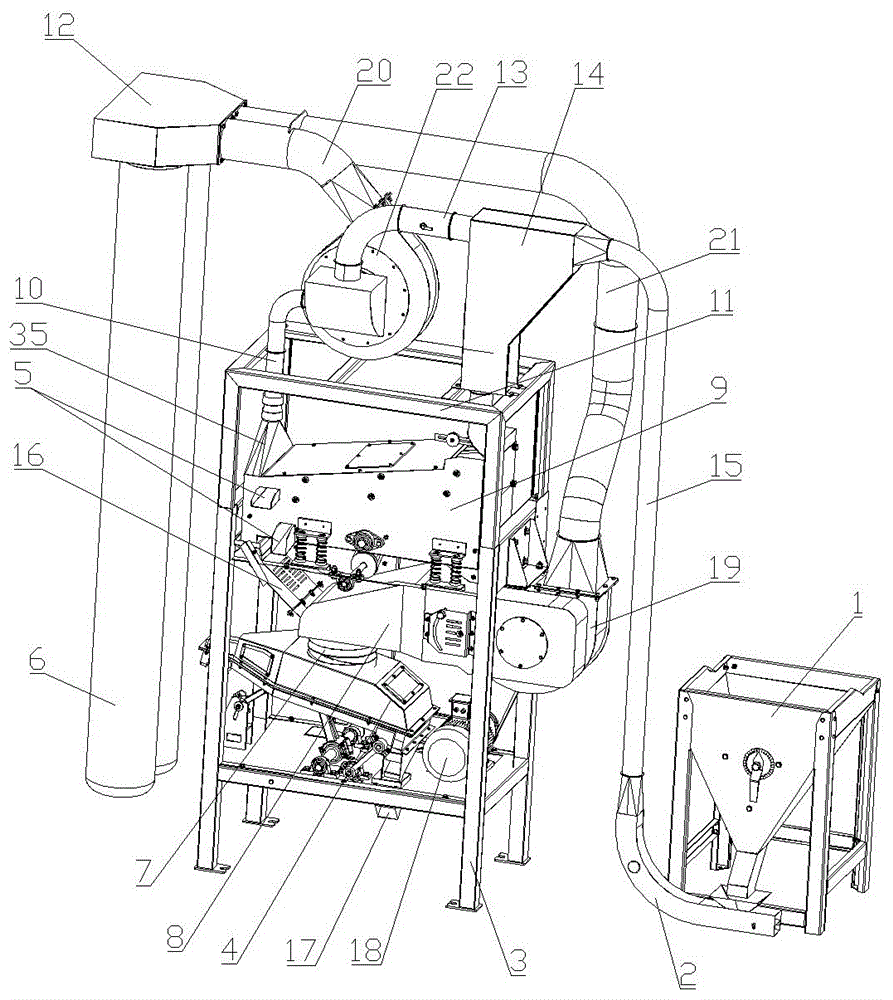

Combined stand-alone grain fanner

A combined and stand-alone technology, which is applied in the direction of solid separation, separation of solids from solids with airflow, chemical instruments and methods, etc., can solve problems such as uneven air volume on the screen surface, dust pollution, and unfiltered wind, etc. Achieve the effects of reducing the probability of accidents, reducing labor intensity, and saving fan energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] Embodiment: material: raw grain wheat

[0036] Minimum wind volume: 150m 3 / h~300m 3 / h

[0037] Minimum pressure: 234kg / ㎡~330kg / ㎡

[0038] Above, the output of the equipment is 500kg / h, the wind speed in the air duct is 20-25m / s, and the conveying concentration is: 2-4 (ratio: the weight of the material conveyed per unit time / the weight of air passing through the conveying pipe per unit time), The pipe diameter takes the range value calculated from φ70mm~80mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com