Fabric knitting method

A kind of braided fabric, the technology of the other side, applied in the weaving field of braided fabrics, can solve the problems of braided yarn disconnection, small neck hole, insufficient number of coils, etc., and achieve the effect of increasing the number of coils and suppressing yarn disconnection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

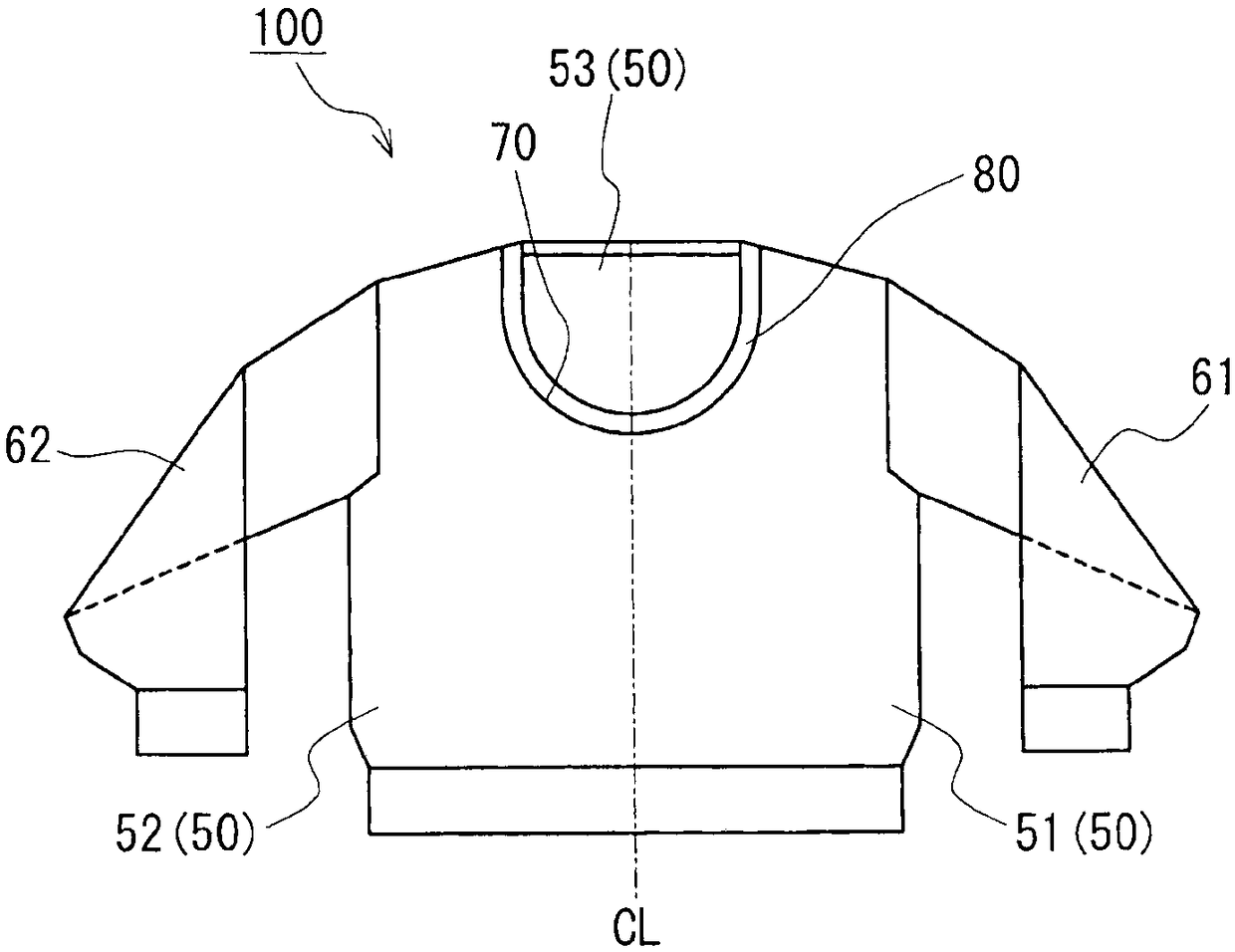

[0040] In Embodiment 1, an example in which a neckline is formed on a knitted pullover (knitted fabric) having a body and sleeves using the knitted fabric knitting method of the present invention will be described.

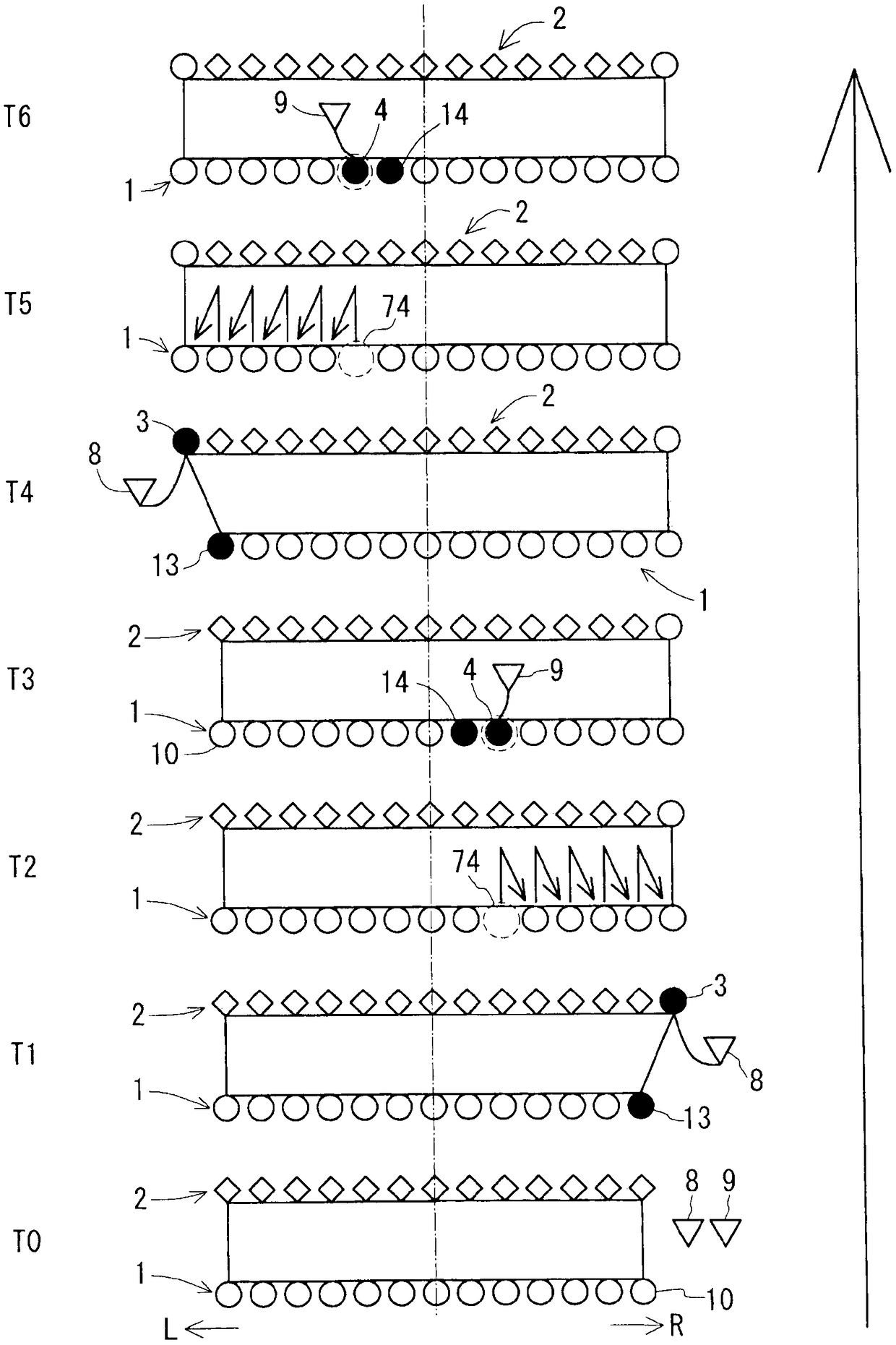

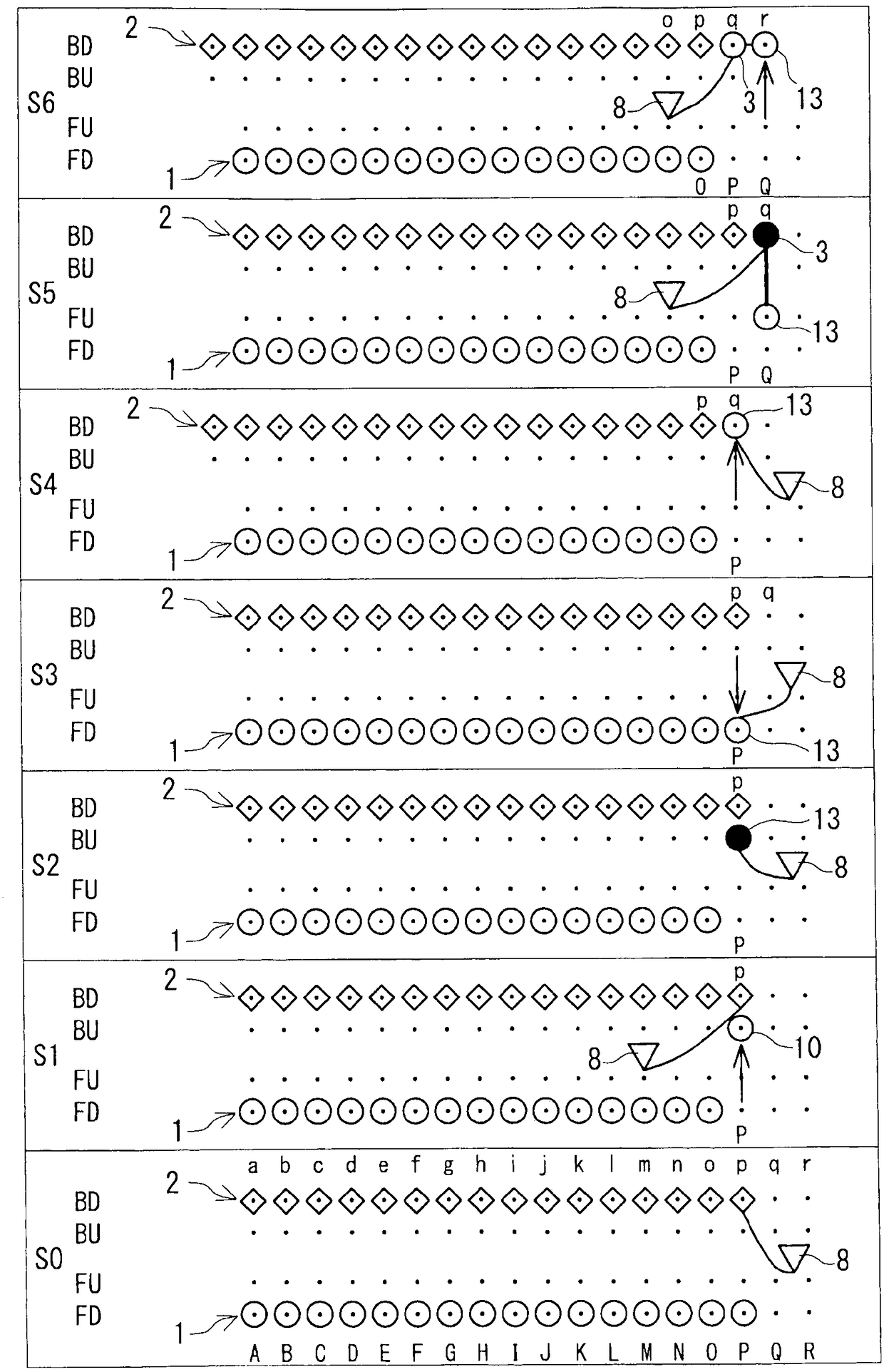

[0041] figure 1 The illustrated knitted pullover 100 (tubular knitted fabric) has a body 50 and sleeves (left sleeve 61 , right sleeve 62 ) of the set-in type. For convenience, the body 50 can be divided into a left front body 51 and a right front body 52 sandwiching the center line CL of the knitted pullover 100 , and a rear body 53 . A substantially U-shaped neckline 70 on the front body side is formed on the body 50 , and a cylindrical collar 80 is provided on the neckline 70 . In order to knit the sweater 100 using a flat knitting machine, the body 50 and the sleeves 61, 62 are knitted up to the position of the neckline 70, and then, with the front body 51, 52 and the back body 53 connected in a cylindrical shape, The number of stitches in the knitting width...

Embodiment approach

[0069] The method for knitting knitted fabrics of the present invention can also be used for knitting knitted fabrics other than sweaters. For example, the knitting method of the knitted fabric of the present invention can also be applied to knitting of openings such as knitted bags. Also, in addition to the one-side knitted fabric portion 1 , widening stitches may be formed on the other-side knitted fabric portion 2 to increase the number of stitches in the knitting width direction of the other-side knitted fabric portion 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com