Layered injection and production integrated pipe column and process

A pipe string and process technology, which is applied in the field of layered injection-production integrated pipe string and process, can solve the problems of complex operation, high crude oil production cost, and low work efficiency, so as to improve production efficiency, simplify well conversion operations, The effect of reducing mining costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

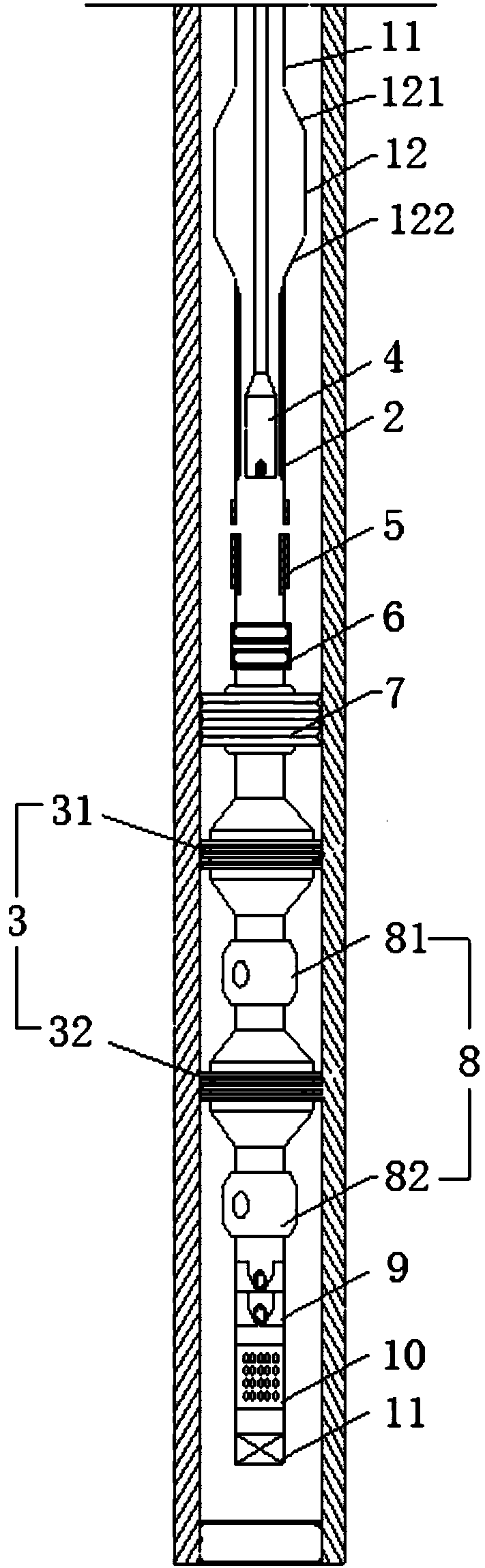

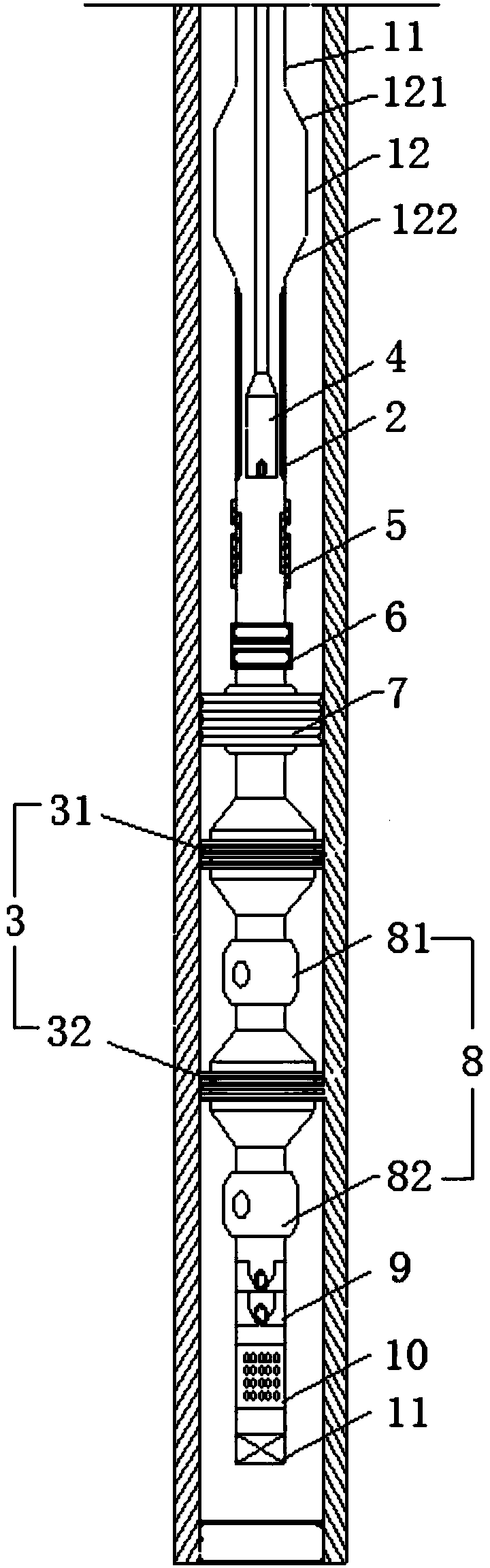

[0041] Such as figure 1 As shown, the embodiment of the present invention provides a layered injection-production integrated pipe string. The pipe string is arranged inside the casing, and the pipe string has an axial inner cavity whose upper end communicates with the wellhead. The pipe string includes:

[0042] The second oil pipe 12, the oil well pump barrel 2 and at least two packers 3 connected sequentially from top to bottom through the first oil pipe 11, and the oil well pump column arranged inside the oil well pump barrel 2 in a dynamic and sealed connection Plug 4;

[0043] Under each packer 3, there is a liquid communication port connecting the inner cavity of the casing and the inner cavity of the pipe string;

[0044] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com